Abstract

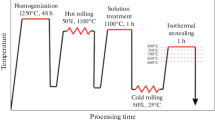

The intercritical annealing treatment at 650 and 700 °C results in two ultrafine-grained (UFG) dual-phase ferrite–austenite steels. The two steels exhibit different and special discontinuous yielding and pronounced Lüders-like strain phenomena with large yielding strain which are related to their retained γ-austenite (RA) volume fractions and RA stabilities. The steel annealed at 650 °C shows an absent or very small strain hardening, while the steel annealed at 700 °C shows an obvious strain hardening upward curvature with increasing strain. The results show that before and during straining, the steel annealed at 650 °C exhibits a mixture of equiaxed and elongated UFG α-ferrite and austenite phases; however, the steel annealed at 700 °C exhibits only elongated UFG α and γ phases. It was found that most of the γ-austenite to α′-martensite transformation occurred at the initial deformation stage and very small or almost no transformation occurred afterward. This demonstrates that the strain-induced martensite (SIM) transformation (γ–α′) or transformation-induced plasticity (TRIP) effect dominates only at the initial deformation stage. RA remained stable, and no TRIP effect was observed at the final deformation stage. The load–unload–reload test was performed to evaluate the back stress (σb) hardening effect. It is believed that the pronounced strain hardening behavior at the later deformation stage is mainly associated with σb enhancement induced by the strain partitioning between the soft and hard phases due to SIM transformation during tensile deformation.

Similar content being viewed by others

References

A. Perlade, A. Antoni, R. Besson, D. Caillard, M. Callahan, J. Emo, A.F. Gourgues, P. Maugis, A. Mestrallet, L. Thuinet, Q. Tonizzo, J.H. Schmitt, Mater. Sci. Technol. 35 (2019) 204–219.

Z.C. Li, X.T. Zhang, Y.J. Mou, R.D.K. Misra, L.F. He, H.P. Li, Mater. Sci. Eng. A 746 (2019) 363–371.

S. Ahmad, L.F. Lv, L.M. Fu, H.R. Wang, W. Wang, A.D. Shan, Acta Metall. Sin. (Engl. Lett.) 32 (2019) 361–371.

D.W. Suh, S.J. Kim, Scripta Mater. 126 (2017) 63–67.

Z.H. Cai, H. Ding, H. Kamoutsi, G.N. Haidemenopoulos, R.D.K. Misra, Mater. Sci. Eng. A 654 (2016) 359–367.

X.G. Wang, L. Wang, M.X. Huang, Acta Mater. 124 (2017) 17–29.

H. Luo, H. Dong, M. Huang, Mater. Des. 83 (2015) 42–48.

J. Ma, H. Liu, Q. Lu, Y. Zhong, L. Wang, Y. Shen, Scripta Mater. 169 (2019) 1–5.

Z.H. Cai, S.Y. Jing, H.Y. Li, K.M. Zhang, R.D.K. Misra, H.H. Ding, Z.Y. Tang, Mater. Sci. Eng. A 739 (2019) 17–25.

B. Sun, F. Fazeli, C. Scott, B. Guo, C. Aranas Jr., X. Chu, M. Jahazi, S. Yue, Mater. Sci. Eng. A 729 (2018) 496–507.

Y. Zhang, H. Ding, Mater. Sci. Eng. A 733 (2018) 220–223.

J.H. Ryu, J.I. Kim, H.S. Kim, C.S. Oh, H.K.D.H. Bhadeshia, D.W. Suh, Scripta Mater. 68 (2013) 933–936.

C. Wang, W. Cao, J. Shi, C. Huang, H. Dong, Mater. Sci. Eng. A 562 (2013) 89–95.

D. Hull, D.J. Bacon, Introduction to dislocations, 5th ed., Elsevier, Amsterdam, 2011.

Z.C. Li, H. Ding, R.D.K. Misra, Z.H. Cai, Mater. Sci. Eng. A 679 (2017) 230–239.

L. Fu, M. Shan, D. Zhang, H. Wang, W. Wang, A. Shan, Metall. Mater. Trans. A 48 (2017) 2179–2192.

L. Fu, Z. Li, H. Wang, W. Wang, A. Shan, Scripta Mater. 67 (2012) 297–300.

X.G. Wang, M.X. Huang, J. Iron Steel Res. Int. 24 (2017) 1073–1077.

B. Sun, F. Fazeli, C. Scott, X. Yan, Z. Liu, X. Qin, S. Yue, Scripta Mater. 130 (2017) 49–53.

Q. Han, Y. Zhang, L. Wang, Metall. Mater. Trans. A 46 (2015) 1917–1926.

M. Abareshi, E. Emadoddin, Mater. Des. 32 (2011) 5099–5105.

K. Steineder, D. Krizan, R. Schneider, C. Béal, C. Sommitsch, Acta Mater. 139 (2017) 39–50.

H. Wang, Y. Zhang, G. Yuan, J. Kang, Y. Wang, R.D.K. Misra, G. Wang, Mater. Sci. Eng. A 737 (2018) 176–181.

J. Zhang, H. Ding, R.D.K. Misra, C. Wang, Mater. Sci. Eng. A 611 (2014) 252–256.

Z.C. Li, H. Ding, R.D.K. Misra, Z.H. Cai, H.X. Li, Mater. Sci. Eng. A 672 (2016) 161–169.

Z.C. Li, R.D.K. Misra, Z.H. Cai, H.X. Li, H. Ding, Mater. Sci. Eng. A 673 (2016) 63–72.

Z. Cai, H. Ding, X. Xue, J. Jiang, Q. Xin, R. Misra, Scripta Mater. 68 (2013) 865–868.

I. Gutiérrez-Urrutia, D. Raabe, Acta Mater. 60 (2012) 5791–5802.

Z.H. Cai, H. Ding, R.D.K. Misra, Z.Y. Ying, Acta Mater. 84 (2015) 229–236.

Z.H. Cai, H. Ding, R.D.K. Misra, S.Q. Qiguan, Mater. Sci. Eng. A 652 (2016) 205–211.

P.L. Mangonon, G. Thomas, Metall. Trans. 1 (1970) 1577–1586.

G.B. Olson, M. Cohen, Metall. Trans. A 7 (1976) 1905–1914.

J. Rajagopalan, C. Rentenberger, H.P. Karnthaler, G. Dehm, M.T.A. Saif, Acta Mater. 58 (2010) 4772–4782.

A.A. Saleh, E.V. Pereloma, B. Clausen, D.W. Brown, C.N. Tomé, A.A. Gazder, Acta Mater. 61 (2013) 5247–5262.

X. Feaugas, Acta Mater. 47 (1999) 3617–3632.

X. Wu, M. Yang, F. Yuan, G. Wu, Y. Wei, X. Huang, Y. Zhu, PNAS 112 (2015) 14501–14505.

M.X. Yang, F.P. Yuan, Q.G. Xie, Y.D. Wang, E. Ma, X.L. Wu, Acta Mater. 109 (2016) 213–222.

M. Yang, Y. Pan, F. Yuan, Y. Zhu, X. Wu, Mater. Res. Lett. 4 (2016) 145–151.

L. Thilly, S.V. Petegem, P.O. Renault, F. Lecouturier, V. Vidal, B. Schmitt, H.V. Swygenhoven, Acta Mater. 57 (2009) 3157–3169.

A.T. Jennings, C. Gross, F. Greer, Z.H. Aitken, S.W. Lee, C.R. Weinberger, J.R. Greer, Acta Mater. 60 (2012) 3444–3455.

Acknowledgements

This work was financially supported by the Joint Research Center for Future Iron and Steel, SJTU & Baosteel. The author (L.M. Fu) is grateful to the financial support from Startup Fund for Youngman Research at SJTU (SFYR at SJTU, No. 18X100040023).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ahmad, S., Han, Z., Fu, Lm. et al. Tensile behavior of ultrafine-grained low carbon medium manganese steel by intercritical annealing treatment. J. Iron Steel Res. Int. 27, 1433–1445 (2020). https://doi.org/10.1007/s42243-020-00405-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00405-0