Abstract

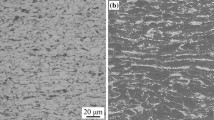

Low-carbon (0.08 wt% C) steel has been subjected to three different heat treatments to obtain dual-phase steels with different microstructures. An understanding of structure–property was established through tensile tests, in conjunction with scanning electron microscope and transmission electron microscope. The results show that the steel after intermediate quenching (IQ) consisting of fine and fibrous martensite exhibited the intermediate strength, highest elongation and the best comprehensive performance of mechanical properties, whereas the steel subjected to intercritical annealing (IA) produced a network martensite along ferrite grain boundaries, having the lowest strength and intermediate elongation. Besides, step quenching (SQ) resulted in a coarse and blocky ferrite–martensite microstructure showing the worst mechanical properties of the three different heat-treatment conditions. The strain-hardening behavior was studied through the modified Crussard–Jaoul model, indicating two stages of strain-hardening behavior for all three samples. The highest magnitude of strain-hardening ability was obtained by IQ annealing routes. The analysis of the fractured surface revealed that ferrite/martensite interfaces are the most susceptible for microvoid nucleation. However, martensite microcracks were also observed in SQ sample, and the microvoids are nucleated within the ferrite grain in IA sample as well. The variations in strength, elongation, strain-hardening behavior and fracture mechanism of the steel with different heat-treatment schedules were further discussed in relation to the microstructural features.

Similar content being viewed by others

References

J. Kadkhodapour, A. Butz, S. Ziaei-Rad, Acta Mater. 59, 2575 (2011)

A. Huseyin, K.Z. Havva, K. Ceylan, J. Iron. Steel Res. Int. 17, 73 (2010)

J.J. Luo, W. Shi, Q.L. Huang, L. Li, J. Iron. Steel Res. Int. 17, 54 (2010)

R.O. Rocha, T.M.F. Melo, E.V. Pereloma, D.B. Santos, Mater. Sci. Eng., A 391, 296 (2005)

G.A. Cingara, Y. Ososkov, M.K. Jain, D.S. Wilkinson, Mater. Sci. Eng., A 516, 7 (2009)

M. Asadi, B.C.D. Cooman, H. Palkowski, Mater. Sci. Eng., A 538, 42 (2012)

H. Ghassemi-Armaki, R. Maab, S.P. Bhat, Acta Mater. 62, 197 (2014)

Y. Sun, X.F. Li, X.Y. Yu, Acta Metall. Sin. (Engl. Lett.) 27, 101 (2014)

M. Koyama, C.C. Tasan, E. Akiyama, K. Tsuzaki, D. Raabe, Acta Mater. 70, 174 (2014)

X. Sun, K.S. Choi, W.N. Liu, M.A. Khaleel, Int. J. Plast 25, 1888 (2009)

J. Kadkhodapour, S. Schmauder, D. Raabe, S. Ziaei-Rad, U. Weber, M. Calcagnotto, Acta Mater. 59, 4387 (2011)

C.C. Tasan, J.P.M. Hoefnagels, M.G.D. Geers, Scr. Mater. 63, 316 (2010)

H. Ghadbeigi, C. Pinna, S. Celotto, J.R. Yates, Mater. Sci. Eng., A 527, 5026 (2010)

N. Peranio, Y.J. Li, F. Roters, D. Raabe, Mater. Sci. Eng., A 527, 4161 (2010)

A. Bag, K.K. Ray, E.S. Dwarakadasa, Metall. Mater. Trans. A 30, 1193 (1999)

M.A. Maleque, Y.M. Poon, H.H. Masjuki, J. Mater. Process. Technol. 153–154, 482 (2004)

D. Das, P.P. Chattopadhyay, J. Mater. Sci. 44, 2957 (2009)

N.J. Kim, G. Thomas, Metall. Trans. A 12, 483 (1981)

G. Speich, V. Demarest, R. Miller, Metall. Mater. Trans. A 12, 1419 (1981)

M. Calcagnotto, Y. Adachi, D. Ponge, D. Raabe, Acta Mater. 59, 658 (2011)

M. Calcagnotto, D. Ponge, D. Raabe, Mater. Sci. Eng., A 527, 7832 (2010)

N. Saeidi, F. Ashrafizadeh, B. Niroumand, Mater. Sci. Eng., A 599, 145 (2014)

Y. Mazaheri, A. Kermanpur, A. Najamizadeh, ISIJ Int. 55, 218 (2015)

Y. Mazaheri, A. Kermanpur, A. Najafizadeh, Mater. Sci. Eng., A 619, 1 (2014)

A.R. Marder, Metall. Trans. A 13, 85 (1982)

K. Park, M. Nishiyama, N. Nakada, T. Tsuchiyama, Mater. Sci. Eng., A 604, 135 (2014)

A. Karmakar, M. Ghosh, D. Chakrabarti, Mater. Sci. Eng., A 564, 389 (2013)

T. Bhattacharyya, T. Sakaki, G.J. Weng, Metall. Trans. A 24, 301 (1993)

A. Hüseyin, K.Z. Havva, K. Ceylan, J. Iron. Steel Res. Int. 17, 73 (2010)

A. Bayram, A. Uguz, M. Ula, Mater. Charact. 43, 259 (1999)

P. Li, J. Li, W.B. Hua, D.H. Xu, J. Alloys Compd. 578, 320 (2013)

R.R. Mohanty, O.A. Girina, N.M. Fonstein, Metall. Mater. Trans. A 42, 3680 (2011)

M. Türkmen, S. Gündüz, Acta Metall. Sin. (Engl. Lett.) 27, 279 (2014)

H.F. Lan, X.H. Liu, L.X. Du, Acta Metall. Sin. (Engl. Lett.) 25, 443 (2012)

K.T. Park, S.Y. Han, B.D. Ahn, D.H. Shin, Y.K. Lee, K.K. Um, Scr. Mater. 51, 909 (2004)

M. Calcagnotto, D. Ponge, D. Raabe, ISIJ Int. 48, 1096 (2008)

V. Colla, M. De Sanctis, A. Dimatteo, Metall. Mater. Trans. 40, 2557 (2009)

W.J. Nie, C.J. Shang, H.L. Guan, X.B. Zhang, S.H. Chen, Acta Metall. Sin. 48, 298 (2012). (in Chinese)

Y.I. Son, Y.K. Lee, K.T. Park, C.S. Lee, D.H. Shin, Acta Mater. 53, 3125 (2005)

Y. Mazaheri, A. Kermanpur, A. Najafizadeh, N. Saeidi, Mater. Sci. Eng., A 612, 54 (2014)

N.K. Balliger, T. Gladman, Met. Sci. 15, 95 (1981)

M. Mazinani, W.J. Poole, Metall. Mater. Trans. A 38, 328 (2007)

M. Sarwar, J. Mater. Sci. 31, 2091 (1996)

P. Uggowitzer, H.P. Stüwe, Mater. Sci. Eng. 55, 181 (1982)

Acknowledgments

This work was financially supported by the National Key Project of Scientific and Technical Supporting Programs of China (No. 2011CB606306-2) and the National Natural Science Foundation of China (Grant No. 51204048).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Deng, YG., Di, HS. & Zhang, JC. Effect of Heat-Treatment Schedule on the Microstructure and Mechanical Properties of Cold-Rolled Dual-Phase Steels. Acta Metall. Sin. (Engl. Lett.) 28, 1141–1148 (2015). https://doi.org/10.1007/s40195-015-0305-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-015-0305-x