Abstract

Introduction

Pd/Ti double-layer thin film as non-evaporable getter (NEG) was deposited by sublimation, and its activation temperature was as low as 100 °C. The Pd film was deposited in situ after Ti deposition to ensure no oxidization on Ti film.

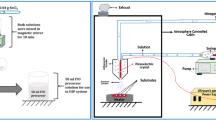

Pumping speed test and characterization method

The pumping speed of the coated pipe was measured by a pumping speed test system. The sticking factor was calculated by Molflow. The surface morphology was observed by a scanning electron microscope (SEM). The chemical composition of the film was measured by an energy-dispersive spectrum inbuilt with the SEM. The crystalline structure of the film was measured using grazing incidence X-ray diffraction.

Conclusion

It was found that the pumping performance of the Pd/Ti film still remained high after 15 times of activation. The maximum pumping speed after heating at 100 °C for 24 h was 1.1 L/s cm2 and 0.49 L/s cm2 for H2 and CO, respectively. It can be concluded that the key to reducing the activation temperature of NEG materials is to enhance the oxidation resistance of the surface of NEG.

Similar content being viewed by others

References

C. Benvenuti, P. Chiggiato, Vacuum 44, 511 (1993)

C. Benvenuti, P. Chiggiato, J. Vac. Sci. Technol. A 14, 3278 (1996)

C. Benvenuti, P. Chiggiato, P. Costa Pinto, A. Escudeiro Santana, T. Hedley, A. Mongelluzzo, V. Ruzinov, I. Wevers, Vacuum 60, 57–65 (2001)

C. Benvenuti, P. Chiggiato, F. Cicoira, Y. L’Aminot, V. Ruzinov, Vacuum 73, 139–144 (2004)

O.B. Malyshev, R. Valizadeh, A.N. Hannah, Vacuum 100, 26–28 (2014)

T. Miyazawa, M. Kurihara, S. Ohno, N. Terashima, Y. Natsui, H. Kato, A. Hashimoto, T. Kikuchi, K. Mase, J. Vac. Sci. Technol. A 36, 051601 (2018)

T. Miyazawa, Y. Kano, Y. Nakayama, K. Ozawa, T. Iga, M. Yamanaka, A. Hashimoto, T. Kikuchi, K. Mase, J. Vac. Sci. Technol. A 37, 021601 (2019)

R.K. Sharma, S. Bhattacharya, R.B. Tokas, K.G. Bhushan, S.C. ShashwatiSen, A. Gadkari, S.K. Gupta, J. Alloys Compd. 651, 375–381 (2015)

P. Chiggiato, P. Costa Pinto, Thin Solid Films 515, 382–388 (2006)

A. Noordermeer, G.A. Kok, B.E. Nieuwenhuys, Surf. Sci. 165, 375 (1986)

Funding

The funding was provided by National Development and Reform Commission (Grand No. 发改高技(2017)2173号).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhiwei, Z., Yuchen, Y., Yongsheng, M. et al. Deposition and characterization of Pd–Ti thin film by sublimation. Radiat Detect Technol Methods 4, 465–471 (2020). https://doi.org/10.1007/s41605-020-00199-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41605-020-00199-5