Abstract

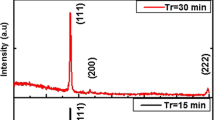

In this study, we first fabricated ITO thin film samples on glass substrates at 300 °C temperature by ultrasonic spray pyrolysis technique. Then three different groups of samples were prepared under three different medium conditions. Some of these samples were annealed at 475 °C in an atmospheric medium and the other two group of samples were annealed at the same temperature, but in different media in which flowing N2 with 150 and 250 L/h. Structural, morphological, electric and electronic, and optical properties of these samples were determined by X-ray diffraction, scanning electron microscope, atomic force microscope, ultraviolet–visible spectrometer, and cryostat measurements. These measurements showed that increasing nitrogen (N2) flow rate in annealing improved the structural properties of the films by almost doubling crystallinity, but bandgap energy of the samples decreased. It was seen that with this increasing the N2 flow rate slightly reduced the transmittance of the films. In addition, Hall measurements have shown that the resistivity of the films decreased from \(1.65\times {10}^{-2}\) to \(1.19\times {10}^{-2}\) Ω cm by introducing the N2 gas. It has also been shown that annealing under N2 gas flow is a method that can be used efficiently to reduce the Oxygen (O2) ratio in the ITO thin films.

Similar content being viewed by others

References

Exarhos, G.J.; Zhou, X.D.: Discovery-based design of transparent conducting oxide films. Thin Solid Films 515, 7025–7052 (2007). https://doi.org/10.1016/j.tsf.2007.03.014

Fauzia, V.; Yusnidar, M.N.; Lalasari, L.H.; Subhan, A.; Umar, A.A.: High figure of merit transparent conducting Sb-doped SnO2thin films prepared via ultrasonic spray pyrolysis. J. Alloy Compd. 720, 79–85 (2017). https://doi.org/10.1016/j.jallcom.2017.05.243

Ginley, D.S.; Bright, C.; Edi, G.: Transparent. MRS Bull. (2000). https://doi.org/10.1557/mrs2000.256

Fortunato, E.; Ginley, D.; Hosono, H.; Paine, D.C.: Transparent conducting oxides for photovoltaics. MRS Bull. 32, 242–247 (2007). https://doi.org/10.1557/mrs2007.29

Livage, J.; Ganguli, D.: Sol–gel electrochromic coatings and devices: a review. Sol. Energy Mater. Sol. Cells 68, 365–381 (2001). https://doi.org/10.1016/S0927-0248(00)00369-X

Granqvist, C.G.; Hultåker, A.: Transparent and conducting ITO films: new developments and applications. Thin Solid Films 411, 1–5 (2002). https://doi.org/10.1016/S0040-6090(02)00163-3

Aegerter, M.A.; Al-Dahoudi, N.: Wet-chemical processing of transparent and antiglare conducting ITO coating on plastic substrates. J. Sol–Gel Sci. Technol. 27, 81–89 (2003). https://doi.org/10.1023/A:1022636112130

Minami, T.: Transparent conducting oxide semiconductors for transparent electrodes. Semicond. Sci. Technol. (2005). https://doi.org/10.1088/0268-1242/20/4/004

Granqvist, C.G.: Transparent conductors as solar energy materials: a panoramic review. Sol. Energy Mater. Sol. Cells 91, 1529–1598 (2007). https://doi.org/10.1016/j.solmat.2007.04.031

Parola, S.; Verdenelli, M.; Sigala, C.; Scharff, J.P.; Velez, K.; Veytızou, C.; Quinson, J.F.: Sol–gel coatings on non-oxide planar substrates and fibers: a protection barrier against oxidation and corrosion. J. Sol–Gel Sci. Technol. 26, 803–806 (2003). https://doi.org/10.1023/A:1020739330499

Moholkar, A.V.; Pawar, S.M.; Rajpure, K.Y.; Patil, P.S.; Bhosale, C.H.; Kim, J.H.: Temperature-dependent properties of spray-deposited ITO thin films. J. Therm. Spray Technol. 19, 531–540 (2010). https://doi.org/10.1007/s11666-009-9412-4

Godt, J.J.; Scheidig, F.; Grosse-Siestrup, C.; Esche, V.; Brandenburg, P.; Reich, A.; David, A.; Groneberg, D.A.: The toxicity of cadmium and resulting hazards for human health. J. Occup. Med. Toxicol. (2006). https://doi.org/10.1186/1745-6673-1-22

Gupta, S.; Yadav, B.C.; Dwivedi, P.K.; Das, B.: Microstructural, optical and electrical investigations of Sb-SnO2thin films deposited by spray pyrolysis. Mater. Res. Bull. 48(9), 3315–3322 (2013). https://doi.org/10.1016/j.materresbull.2013.05.001

Fauzia, V.; Yusnidar, M.N.; Lalasari, L.H.; Subhan, A.; Umar, A.A.: High figure of merit transparent conducting Sb-doped SnO2 thin films prepared via ultrasonic spray pyrolysis. J. Alloy Compd. 720, 79–85 (2017). https://doi.org/10.1016/j.jallcom.2017.05.243

Kim, S.S.; Choi, S.Y.; Park, C.G.; Jin, H.W.: Transparent conductive ITO thin films through the sol–gel process using metal salts. Thin Solid Films Thin Solid Films 347, 155–160 (1999). https://doi.org/10.1016/S0040-6090(98)01748-9

Löffler, J.: Transparent conductive oxides for thin-film silicon solar cells. Utrecht University Repository, PhD thesis, Netherlands, p. 147 (2005)

Sarma, B.K.; Pradhyut, R.P.: Al-doped ZnO transparent conducting oxide with appealing electro-optical properties–Realization of indium free transparent conductors from sputtering targets with varying dopant concentrations. Mater. Today Commun. 23, 100870 (2020). https://doi.org/10.1016/j.mtcomm.2019.100870

Szkutnik, P.D.; Roussel, H.; Lahootun, V.; Mescot, X.; Weiss, F.; Jiménez, C.: Study of the functional properties of ITO grown by metalorganic chemical vapor deposition from different indium and tin precursors. J. Alloy Compd. 603, 268–273 (2014). https://doi.org/10.1016/j.jallcom.2014.03.088

Aouaj, M.A.; Diaz, R.; Belayachi, A.; Rueda, F.; Abd-Lefdil, M.: Comparative study of ITO and FTO thin films grown by spray pyrolysis. Mater. Res. Bull. 44, 1458–1461 (2009). https://doi.org/10.1016/j.materresbull.2009.02.019

Untila, G.G.; Kost, T.N.; Chebotareva, A.B.; Timofeyev, M.A.: Effect of the tin content on the composition and optical and electrical properties of ITO films deposited onto silicon and glass by ultrasonic spray pyrolysis. Semiconductors 46(7), 962–968 (2012). https://doi.org/10.1134/S1063782612070202

Jadsadapattarakul, D.; Euvananont, C.; Thanachayanont, C.; Nukeaw, J.; Sooknoi, T.: Tin oxide thin films deposited by ultrasonic spray pyrolysis. Ceram. Int. 34, 1051–1054 (2008). https://doi.org/10.1016/j.ceramint.2007.09.096

Thirumoorthi, M.; Thomas Joseph Prakash, J.: Structure, optical and electrical properties of indium tin oxide ultra thin films prepared by jet nebulizer spray pyrolysis. J. Asian Ceram. Soc. 4, 124–132 (2016). https://doi.org/10.1016/j.jascer.2016.01.001

Guillén, G.; Herrero, J.: Influence of Oxygen in the deposition and annealing atmosphere on the characteristics of ITO thin films prepared by sputtering at room temperature. Vacuum 80(6), 615–620 (2006). https://doi.org/10.1016/j.vacuum.2005.10.006

Lee, J.; Lim, D.G.; Song, W.; Yi, J.: Influence of annealing temperature and atmosphere on the properties of ITO films deposited using a powdery target. J. Korean Phys. Soc. 51(3), 1143–1146 (2007)

Steckl, A.J.; Mohammed, G.: The effect of ambient atmosphere in the annealing of indium tin oxide films. J. Appl. Phys. 51(7), 3890–3895 (1980). https://doi.org/10.1063/1.328135

Guillén, C.; Herrero, J.: Structure, optical, and electrical properties of indium tin oxide thin films prepared by sputtering at room temperature and annealed in air or nitrogen. J. Appl. Phys. (2007). https://doi.org/10.1063/1.2715539

Mikrajuddin, A.; Khairurrijal, K.: Derivation of scherrer relation using an approach in basic physics course. J. Nanosains Nanotenol. 1(1), 28–32 (2008)

Untila, G.G.; Kost, T.N.; Chebotareva, A.B.: Fluorine and tin-doped indium oxide films grown by ultrasonic spray pyrolysis: characterization and application in bifacial silicon concentrator solar cells. Sol. Energy 159, 173–185 (2018). https://doi.org/10.1016/j.solener.2017.10.068

Park, J.O.; Lee, J.H.; Kim, J.J.; Cho, S.H.; Cho, Y.K.: crystallization of indium tin oxide thin films prepared by RF-magnetron sputtering without external heating. Thin Solid Films 474, 127–132 (2005). https://doi.org/10.1016/j.tsf.2004.08.172

Rozati, S.M.; Ganj, T.: Transparent conductive Sn-doped indium oxide thin films deposited by spray pyrolysis technique. Renew. Energy 29(10), 1671–1676 (2004). https://doi.org/10.1016/j.renene.2004.01.008

Lee, J.H.; Kim, Y.H.; Ahn, S.J.; Ha, T.H.; Kim, H.S.: Grain-size effect on the electrical properties of nanocrystalline indium tin oxide thin films. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 199, 37–41 (2015). https://doi.org/10.1016/j.mseb.2015.04.011

Tauc, J.; Menth, A.: States in the gap. J. Non-Cryst. Solids 8–10, 569–585 (1972)

Jongthammanurak, S.; Witana, M.; Cheawkul, T.; Thanachayanont, C.: The effects of carrier gas and substrate temperature on ZnO films prepared by ultrasonic spray pyrolysis. Mater. Sci. Semicond. Process. 16(3), 625–632 (2013). https://doi.org/10.1016/j.mssp.2012.11.009

Adedokun, O.: Review on transparent conductive oxides thin films deposited by sol–gel spin coating technique. Int. J. Eng. Sci. Appl. 2(3), 88–97 (2018)

Acknowledgements

We thank Prof. Dr. Refik KAYALI for his help in the reduction and his contribution to improving our manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Koç, M., Kaleli, M. & Öztürk, M. Effect of Nitrogen Flow Rate During Annealing on Structural and Electro-optical Properties of ITO Thin Films Deposited by Ultrasonic Spray Pyrolysis. Arab J Sci Eng 47, 7707–7716 (2022). https://doi.org/10.1007/s13369-021-06553-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06553-z