Abstract

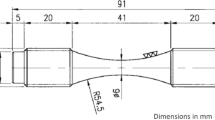

Low cycle fatigue experiments were performed on nickel-based alloy 617M at different temperatures ranging from 300 to 1123 K. Samples were machined from a forged block of 800 mm diameter of the alloy. The alloy exhibited continuous cyclic hardening up to the macrocrack initiation followed by a rapid stress drop until the final failure at all the temperatures except 300 K, 473 K and 1123 K where saturation was observed between the initial hardening and the final stress drop. The above observations indicate the difference in the deformation mechanisms at the above temperature extremities compared to the intermediate temperature range of 573–1023 K. The extent of cyclic hardening increased initially with the strain amplitude and saturated whereas, with the increase in temperature, it increased up to 973 K followed by a reduction with further increase. Type-C serrations were observed in the temperature range of 573–1123 K. However, the serrations disappeared with progressive cycling and matrix hardening persisted and seemed to be more predominant at the later stage of cycling, resulting in cyclic hardening up to macrocrack initiation. Stress drops curves of a serrated flow were used to understand the effect of precipitates on the alloy behavior. All the samples failed in transgranular mode. The data generated was used to arrive at the fatigue design curves for the alloy.

Similar content being viewed by others

Availability of Data and Material

The experimental data cannot be shared at this stage because it also forms part of a further investigation.

Code Availability

Not applicable.

References

Alok M, Bhutani OP, Jayakumar T, Dubey DK, Chetal SC (2013) Advances in materials technology for fossil power plants. In: Proceedings from the Seventh International Conference. Electric Power Research Institute, USA: 53

ASTM E606 (1994) Standard recommended practice for constant-amplitude low-cycle fatigue testing.Annual Book of ASTM Standards. ASTM, Philadelphia

Burke MA, Beck CG (1984) High temperature low cycle fatigue behavior of the nickel base alloy IN-617. MTA 15:661–670. https://doi.org/10.1007/BF02644197

Cui CY, Tian CG, Zhou YZ, Jin T, Sun XF (2012) Dynamic strain aging in Ni base alloys with different stacking fault energy. In: Huron ES, Reed RC, Hardy MC, Mills MJ, Montero RE, Portella PD, Telesman J (eds) Superalloys 2012. Wiley, Hoboken: 715–722. https://doi.org/10.1002/9781118516430.ch79

Dewa RT, Park JH, Kim SJ, Kim WG, Kim ES, Haryadi GD, Ekaputra IMW (2018) A review of low-cycle fatigue of Alloy 617 for use in VHTR components: experimental outlook. In: MATEC Web of Conferences: 02049–02055. https://doi.org/10.1051/matecconf/201815902049

Gopinath K, Gogia AK, Kamat SV, Ramamurty U (2009) Dynamic strain ageing in Ni-base superalloy 720Li. Acta Mater 57:1243–1253. https://doi.org/10.1016/j.actamat.2008.11.005

Hosier JC, Tillack DJ (1972) INCONEL alloy 617: a new high-temperature alloy. Met Eng Quart 12:51–55

Li Z, Zhang L, Sun N, Fu L, Shan A (2015) Grain size dependence of the serrated flow in a nickel based alloy. Mater Lett 150:108–110. https://doi.org/10.1016/j.matlet.2015.03.007

Mariappan K, Shankar V, Goyal S, Sandhya R, Laha K, Bhaduri AK (2016) Strain amplitude and temperature effects on the low cycle fatigue behavior of Alloy 617M. Trans Indian Inst Met 69:325–329. https://doi.org/10.1007/s12666-015-0784-5

Narayanan A, Dubey K, Davies CM, Dear JP (2017) The creep of alloy 617 at 700 °C: material properties, measurement of strain and comparison between finite element analysis and digital image correlation. Int J Solids Struct 129:195–203. https://doi.org/10.1016/J.IJSOLSTR.2017.08.021

Rao KBS, Schiffers H, Schuster H, Nickel H (1988) Influence of time and temperature dependent processes on strain controlled low cycle fatigue behavior of alloy 617. Metall Trans A 19:359–371. https://doi.org/10.1007/BF02652546

Rao CV, Srinivas NCS, Sastry GVS, Singh V (2019a) Dynamic strain aging, deformation and fracture behaviour of the nickel base superalloy Inconel 617. Mater Sci Eng A 742:44–60. https://doi.org/10.1016/J.MSEA.2018.10.123

Rao CV, Srinivas NCS, Sastry GVS, Singh V (2019b) Low cycle fatigue, deformation and fracture behaviour of Inconel 617 alloy. Mater Sci Eng A 765:138286. https://doi.org/10.1016/J.MSEA.2019.138286

Ren W, Swindeman RW (2005) Development of a controlled material specification for Alloy 617 for nuclear applications, In: ORNL/TM--2005/504, United States. https://doi.org/10.2172/1034357

Rodriguez P (1984) Serrated plastic flow. Bull Mater Sci 6:653–663. https://doi.org/10.1007/BF02743993

Shankar V, Kumar A, Mariappan K, Sandhya R, Laha K, Bhaduri AK, Narasaiah N (2017) Occurrence of dynamic strain aging in Alloy 617M under low cycle fatigue loading. Int J Fatigue 100:12–20. https://doi.org/10.1016/J.IJFATIGUE.2017.03.001

Smith GD, Yates DH (1991) Optimization of the fatigue properties of INCONEL Alloy 617. In: ASME International Gas Turbine and Aero Engine Congress and Exposition. American Society of Mechanical Engineers, Orlando: 1–5. https://doi.org/10.1115/91-GT-161

Tan L, Sridharan K, Allen TR (2007) Effect of thermomechanical processing on grain boundary character distribution of a Ni-based superalloy. J Nucl Mater 371:171–175. https://doi.org/10.1016/J.JNUCMAT.2007.05.002

Yuan Y, Gu YF, Osada T, Zhong ZH, Yokokawa T, Harada H (2012) A new method to strengthen turbine disc superalloys at service temperatures. Scr Mater 66:884–889. https://doi.org/10.1016/j.scriptamat.2012.01.025

Acknowledgements

The authors would like to thank Dr. C. Chetal, Director, Indian AUSC Mission, New Delhi, Dr. Shaju K Albert, Directo, MMG, Dr. M Vasudevan, Head, MDTD, IGCAR for allowing us to do present work and BHEL, Hyderabad for providing alloy 617M forged rod. We would also thank Shri Vetrivendan, SO-E, IGCAR and Shri Paulson Varghese, SRF, IGCAR for assisting in the SEM investigations.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Conceptualization, Experimentation, Data analysis and investigation, Writing—original draft preparation: JV; Experimentation, review and editing: RK; Conceptualization, Writing—review and editing: SG; Conceptualization, Supervision Writing – Final editing: AN.

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Veerababu, J., Kannan, R., Goyal, S. et al. Low Cycle Fatigue Behavior of Forged Alloy 617M. Trans Indian Natl. Acad. Eng. 7, 417–424 (2022). https://doi.org/10.1007/s41403-021-00292-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41403-021-00292-1