Abstract

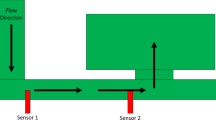

Mold wall collapse in the lost foam casting process has been largely associated with poor sand compaction where pattern design and glue line placement has been overlooked. In this paper, the design and location of glue joints is studied to determine its role in mold wall collapse, by measuring time for the metal front to pass through a directional glue joint. Using high-temperature glass, the flow of the metal and the kinetic zone was tracked with a high-speed camera and thermocouples were used to measure the time and temperature of the metal front. It was found that location of glue joints and glue type can cause sand collapse in addition to poor sand compaction.

Similar content being viewed by others

References

J. Belke, K. Bieniewicz, M. Reich, P. Sanders, N. Soraruf, and A. Steer, Improving metal flow in lost foam casting through use of low thermal degradation hot melt adhesives, 2023-037.

W. Sun, H.E. Littleton, Real-time X-ray visualization of effects of glue joints on metal filling and defect formation of lost foam castings. AFS Trans. 113, 1099–1107 (2005)

A. Sharifi, M.M.H. Abadi, R. Ashiri R, Direct observation of effects of foam density, gating design and pouring temperature on mold filling process in lost foam casting of A356 Alloy. In: Proceedings of the TMS Middle East – Mediterranean Materials Congress on Energy and Infrastructure Systems, MEMA 2015.

M. Sands, S. Shivkumar, Influence of coating thickness and sand fineness on mold filling in the lost foam casting process. J Mater Sci. 38, 667–673 (2003)

M. Hill, A.E. Vrieze, T.L. Moody, C.W. Ramsay, D.R. Askeland, Effect of metal velocity on defect. Formation in Al LFCs. AFS Trans. 106, 365–374 (1998)

S. Sulaiman, M.K.A.M. Ariffin, S.H. Tang, A. Saleh, Influence of pattern coating thickness on porosity and mechanical properties of lost foam casting of Al-Si (LM6) Alloy. Appl. Mech. Mater. 300–301, 1281–1284 (2013)

J.M. Jeon, S.J. Lee, K.H. Choe, J.S. Huh, Gas pressure effect on sand collapse in kinetic zone of lost-foam casting. Adv Mater Sci Eng. 4, 1–9 (2020)

Acknowledgement

I would like to thank my co-author Jacob A. Belke and everyone at Mercury Marine, Fond du Lac, WI. for their assistance, guidance and support on my project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Allen, K.R., Belke, J.A. IJMC/FEF Student Research Competition. Inter Metalcast 18, 23–29 (2024). https://doi.org/10.1007/s40962-023-01185-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01185-5