Abstract

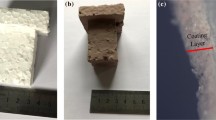

Lost foam casting minimizes pattern design limitations by using pattern segments and hot melt adhesives to create complex geometries. Defects in cast parts have been shown to be caused by the higher thermal degradation energy densities in hot melt adhesives as compared to polystyrene. A polystyrene-based glue was designed to achieve a lower thermal degradation energy, measured via thermal gravimetric analysis, while maintaining qualitative metrics such as low odor and proper viscosity to avoid stringing during application. Casting trials were performed for multiple developed glue mixtures to assess the melt front velocities at each glue joint. The resulting polystyrene-based glue increased the melt front velocity by 75% at the glue joint compared to a commercial glue. The addition of a wax component increased the melt front velocity further and eliminated stringing upon application.

Similar content being viewed by others

References

K.A. Guler, A. Kisasoz, A. Karaaslan, A study of expanded polyethylene (EPE) pattern application in aluminium lost foam casting. Rus. J. Non-Ferrous Metals. 56(2), 171–176 (2015)

D.M. Matson, R. Venkatesh, S. Biederman, Expanded polystyrene lost foam casting—modeling bead steaming operations. J. Manuf. Sci. Eng. 129(2), 425–434 (2007)

R. Albonetti, Porosity and intermetallic formation in lost foam casting of 356 alloy (2000)

W. Sun, H.E. Littleton, C.E. Bates, Formation mechanism of gas cavity defects in lost foam iron castings. Int. J. Cast Met. Res. 16(6), 549–553 (2003)

T.C. Pederson, Inventor. Glued lost foam casting pattern assembly. US 7,318,468 B2. November 16, (2008)

K. Allen, J. Belke, IJMC/FEF student research competition. Int. J. Metalcast. 18, 23–29 (2024)

E. Atlas, C.S. Giam, Phthalates and Related Plasticizers, in Mass Spectrometry in Environmental Sciences. ed. by F.W. Karasek, O. Hutzinger, S. Safe (Springer, Boston, 1985), pp.341–351. https://doi.org/10.1007/978-1-4613-2361-7_15

F. Lovering, J. Bikker, C. Humblet, Escape from flatland: increasing saturation as an approach to improving clinical success. J. Med. Chem. 52(21), 6752–6756 (2009)

K. Bieniewicz, M. Reich, N. Soraruf, A. Steer, P. Sanders, J. Belke, Improving metal flow in lost foam casting through use of low thermal degradation hot melt adhesives. AFS Trans. 131, 309–314 (2023)

Acknowledgements

This paper is based upon a presentation made at the 2023 AFS Metalcasting Congress and published in the AFS Transactions, Vol. 131, pp. 303–308 (2023). This research was funded by Brunswick Corporation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper is based upon one in the AFS Transactions Vol. 131.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bieniewicz, K., Reich, M., Soraruf, N. et al. Improving Metal Flow in Lost Foam Casting Through Use of Low Thermal Degradation Hot Melt Adhesives. Inter Metalcast (2024). https://doi.org/10.1007/s40962-024-01331-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-024-01331-7