Abstract

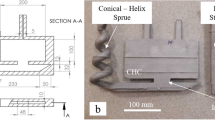

Three-dimensional (3D) printing of sand molds and cores has increasingly been used by foundries to produce castings with complex geometries quickly and economically. While the cost has decreased, 3D sand printing remains a relatively costly process. The technology most commonly used to produce 3D printed sand is binder jetting, a process invented in 1993 by researchers at MIT. Selective powder deposition (SPD) is an additive manufacturing technology developed to produce metal parts. In the process, unbound metal and support powders are deposited in a layer-by-layer fashion to produce the desired geometry. The build structure is then sintered or infiltrated to produce a solid metal product. The focus of this research was to determine if selective powder deposition (SPD) could be used to produce 3D printed sand molds and cores. To test this, an iro3d Model-C SPD printer was obtained and modified to print shell sand as the build medium with unbound silica sand as the support medium. The prints were cured in an oven to bind the shell sand structures. Several 3D model parts were produced to evaluate the capabilities of the printer. The structures produced included a resolution test print and horizontally parted molds. Aluminum castings were successfully produced from the molds. The results indicate that SPD can be used to economically create 3D printed sand molds and cores. This paper will detail modifications made to the SPD printer to produce 3D printed sand structures and the results obtained.

Similar content being viewed by others

References

J. Wang, S.R. Sama, G. Manogharan, Re-thinking design methodology for castings: 3D sand-printing and topology optimization. Int. J. Metalcast. 13(1), 2–17 (2019). https://doi.org/10.1007/s40962-018-0229-0

T. Sivarupan et al., A review on the progress and challenges of binder jet 3D printing of sand moulds for advanced casting. Addit. Manuf. 40, 101889 (2021). https://doi.org/10.1016/j.addma.2021.101889

N. Bryant, T. Frush, J. Thiel, E. MacDonald, J. Walker, Influence of machine parameters on the physical characteristics of 3D-printed sand molds for metal casting. Inter Metalcast 15(2), 361–372 (2021). https://doi.org/10.1007/s40962-020-00486-3

L. Yang, S. Tang, Z. Fan, W. Jiang, X. Liu, Rapid casting technology based on selective laser sintering. China Foundry 18(4), 296–306 (2021). https://doi.org/10.1007/s41230-021-1099-2

“Metal 3D printer - iro3d.” Accessed: Jul. 21, 2022. [Online]. Available: https://iro3d.com/

S. Magalhães et al., Validation of a low-cost selective powder deposition process through the characterization of tin bronze specimens. Proc Insti Mech Eng Part L J Mater Des Appl 235(12), 2681–2691 (2021). https://doi.org/10.1177/14644207211031941

Acknowledgements

This project was funded through NSF REU Site #2051066. The authors gratefully acknowledge the generous technical support provided by Sergey Singov of iro3d.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rios, R., Trueba, L. IJMC/FEF Student Research Competition. Inter Metalcast 18, 40–45 (2024). https://doi.org/10.1007/s40962-023-01182-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-023-01182-8