Abstract

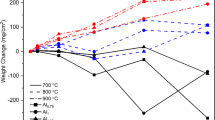

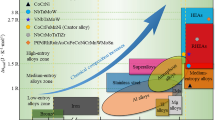

The study added Mn at different rates to the Al–Si–Mg eutectic alloy and heat-treated the quaternary alloy. Therefore, the microstructure morphology of the Al–Si–Mg eutectic alloy was examined after Mn addition and heat treatment. Also determined were the hardness, tensile strength, fracture surface analysis, and thermoelectric characteristics of the newly produced Al–12.95%Si–4.96%Mg–X%Mn [X=0.5, 1.0, and 1.5 (wt.)] alloys. Along with the predicted Si and Mg2Si phases in the Al matrix phase, this investigation found a randomly distributed Mn-rich Al15Mn3Si2 intermetallic phase and a Mg-rich Al5Si3Mg2 phase. Mn-doped samples without heat treatment were somewhat softer than the parent alloy. After heat treatment, the hardness more than doubled for the Al–Si–Mg eutectic system and Mn-doped samples. After heat treatment, the alloy with 1.5% Mn added had the maximum hardness value of 94.3±5.0 HV. Heat treatment improved tensile strength by up to 80%, and the alloy with 0.5% Mn had 144.7 MPa. Melting temperatures (Tm) (K), fusion enthalpy (ΔH) (J/g), and specific heat Cpl (J/gK) were determined for non-heat-treated materials. The 0.5, 1.0, and 1.5 Mn-added samples had Tm of 566.30, 568.96, and 566.40 °C, respectively. The ΔH value of samples with 0.5%, 1.0% and 1.5% Mn addition is 662.29, 657.93 and 639.11, respectively. Cpl was 0.788, 0.781, and 0.761 J/g.K. for 0.5%, 1.0%, and 1.5% Mn-added samples. In both heat-treated and non-heat-treated samples, Mn enhanced electrical resistance.

Similar content being viewed by others

References

D.R. Askeland, P.F. Pradeep, W.J. Wright, The Science and Engineering of Materials, 6th ed. (Cengage Learning, Stamford, 2011)

Y. Kaygisiz, N. Maraşli, Microstructural, mechanical and electrical characterization of directionally solidified Al–Si–Mg Eutectic Alloy. J. Alloys Compd. (2015). https://doi.org/10.1016/j.jallcom.2014.08.056

N.A. Belov, A.N. Alabin, D.G. Eskin, Improving the properties of cold-rolled Al-6%Ni sheets by alloying and heat treatment. Scr. Mater. 50(1), 89–94 (2004). https://doi.org/10.1016/j.scriptamat.2003.09.033

Y. Li, T. Liu, S. Chen, Y. Ren, Effect of Ce inoculation on microstructure and mechanical properties of in situ Al–20%Mg2Si composite. Int. J. Met. 13(2), 331–336 (2019). https://doi.org/10.1007/s40962-018-0252-1

S. Ashkvary, S.G. Shabestari, F. Yavari, Effect of cooling rate on the microstructure and solidification characteristics of Al–20%Mg2Si in situ composites using computer-aided thermal analysis technique. Int. J. Met. 17(1), 322–333 (2023). https://doi.org/10.1007/s40962-022-00771-3

R.S. Rana, R. Purohit, S. Das, Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminum alloys and aluminum alloy composites. Int. J. Sci. Res. Publ. 2(6), 1–7 (2012)

E. Spinelli, I.L. Ferreira, P.R. Goulart, K.S. Cruz, Cellular growth during transient directional solidification of hypoeutectic Al–Fe alloys. J. Alloys Compd. 470, 589–599 (2009). https://doi.org/10.1016/j.jallcom.2008.03.026

F. Prusa, D. Vojtech, A. Michalcová, I. Marek, Materials science & engineering a mechanical properties and thermal stability of Al–Fe–Ni alloys prepared by centrifugal atomisation and hot extrusion. Mater. Sci. Eng. A 603, 141–149 (2014). https://doi.org/10.1016/j.msea.2014.02.081

G. Gustafsson, T. Thorvaldsson, G.L. Dunlop, The influence of Fe and Cr on the microstructure of cast Al–Si–Mg Alloys. Metall. Trans. A 17(January), 45–52 (1986)

X. Cao, J. Campbell, The Solidification Characteristics of Fe-Rich Intermetallics in Al-11. 5Si-0. 4Mg Cast Alloys. Metall. Mater. Trans. A. 35, 1425 (2004)

M. Tocci, R. Donnini, G. Angella, A. Pola, Materials characterization effect of Cr and Mn addition and heat treatment on AlSi3Mg casting alloy. Mater. Charact. 123, 75–82 (2017). https://doi.org/10.1016/j.matchar.2016.11.022

Y.S. Lee, J.H. Cha, S.H. Kim, C.Y. Lim, H.W. Kim, Effect of pre-homogenization deformation treatment on the workability and mechanical properties of AlMg5Si2Mn alloy. Mater. Sci. Eng. A 685, 244–252 (2017). https://doi.org/10.1016/j.msea.2016.12.107

M.N.E. Efzan, H.J. Kong, C.K. Kok, Review: effect of alloying element on Al–Si alloys. Adv. Mater. Res. 845, 355–359 (2014). https://doi.org/10.4028/www.scientific.net/AMR.845.355

M. Emamy, K. Tavighi, B. Pourbahari, A.B. Eradi-Zare, Improvement in tensile and wear properties of As-cast Al-15%Mg2Si composite modified by Zn and Ni. Int. J. Met. 11(4), 790–801 (2017). https://doi.org/10.1007/s40962-016-0125-4

E. Sjölander, S. Seifeddine, The heat treatment of Al–Si–Cu–Mg casting alloys. J. Mater. Process. Technol. 210, 1249–1259 (2010). https://doi.org/10.1016/j.jmatprotec.2010.03.020

C.H. Cacares, I.L. Svensson, J.A. Taylor, Strenght-ductility behaviour of Al–Si–Cu–Mg casting alloys in T6 temper. Int. J. Cast Met. Res. 15, 531–543 (2003)

Y. Yang, S.Y. Zhong, Z. Chen, M. Wang, N. Ma, H. Wang, Effect of Cr content and heat-treatment on the high temperature strength of eutectic Al–Si alloys. J. Alloys Compd. 647, 63–69 (2015). https://doi.org/10.1016/j.jallcom.2015.05.167

D. Casari, T.H. Ludwig, M. Merlin, L. Arnberg, G.G. Luca, The effect of Ni and V trace elements on the mechanical properties of A356 aluminium foundry alloy in As-cast and T6 heat treated conditions. Mater. Sci. Eng. A 610, 414–426 (2014). https://doi.org/10.1016/j.msea.2014.05.059

A. Vajd, A. Samadi, Optimization of centrifugal casting parameters to produce the functionally graded Al–15wt%Mg2Si composites with higher tensile properties. Int. J. Met. 14(4), 937–948 (2020). https://doi.org/10.1007/s40962-019-00394-1

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, D.L. Chen, Ageing characteristics and high-temperature tensile properties of Al–Si–Cu–Mg alloys with micro-additions of Mo and Mn. Mater. Sci. Eng. A 2017(684), 726–736 (2016). https://doi.org/10.1016/j.msea.2016.12.044

S.S.S. Kumari, R.M. Pillai, B.C. Pai, Effects of individual and combined additions of Be, Mn, Ca and Sr on the solidification behaviour, structure and mechanical properties of Al–7Si–0. 3Mg–0. 8Fe Alloy. Mater. Sci. Eng. A 461, 561–573 (2007). https://doi.org/10.1016/j.msea.2007.01.082

Y. Kaygısız, D. Balun, Effect of heat treatment on the mechanical properties and corrosion behaviour of Al–Si–Mg alloy systems. Phys. Metals Metallography 123(14), 1499–1508 (2022). https://doi.org/10.1134/S0031918X22100210

V.S. Zolotorevsky, N.A. Belov, M.V. Glozoff, Plating Aluminium Alloys (Elsevier Ltd., Amsterdam, 2007)

J.J. Valencia, P.N. Quested, Thermophysical properties, in ASM Handbook, Volume 15: Casting; ASM International, vol. 15, pp. 468–481, (2008). https://doi.org/10.1361/asmhba0005240

L.F. Mondolfo, Aluminum Alloys-Structure and Properties (1976). https://doi.org/10.1016/j.msea.2016.07.080

N.A. Belov, D.G. Eskin, A.A. Aksenov. Multicomponent Phase Diagrams Applications for Commercial Aluminum Alloys. (Elsevier Ltd., 2005)

W.J. Boettinger, U.R. Kattner, K.W. Moon, J.H. Perepezko, Methods for Phase Diagram Determination, ed by Zhao J. (Elsevier, 2007)

W.M. Wesley, Chemical Analysis Thermal-Analysis, third, ed by P.J., E., J.D. Winefordner, (Wiley-Interscience Publication, 1986)

Recommended Value of Thermophysical Properties for Selected Commercial Alloys; ed. by Kenneth C, (Mills, England, Cambridge, 2002)

D.R. Gaskell, Introduction to the Thermodynamics Od Materials, Fourth; Gaskell, D. R., ed.; (New York, 2003)

S. Yilmaz, Dy2O3, Eu2O3, Sm2O3 KATKILANMIŞ β-Bi2O3 TİPİ KATI ELEKTROLİTLERİN SENTEZLENMESİ, KARAKTERİZASYONLARI VE KATI HAL OKSİJEN İYONİK İLETKENLİKLERİNİN ARAŞTIRILMASI, GAZİ ÜNİVERSİTESİ, (2008)

I. Kolobnev. Zharoprochnost’liteinyh Alyuminievyh Splavov. Metallurgiya, 320 (1973)

T.M. Smith, M.S. Hooshmand, B.D. Esser, F. Otto, D.W. Mccomb, E.P. George, M. Ghazisaeidi, M.J. Mills, Atomic-scale characterization and modeling of 60°dislocations in a high-entropy alloy. Acta. Mater. 110, 352–363 (2016). https://doi.org/10.1016/j.actamat.2016.03.045

L. Ding, Z. Jia, Z. Zhang, R.E. Sanders, Q. Liu, G. Yang, The natural aging and precipitation hardening behaviour of Al–Mg–Si–Cu alloys with different Mg/Si ratios and Cu additions. Mater. Sci. Eng. A 627, 119–126 (2015). https://doi.org/10.1016/j.msea.2014.12.086

W. Jiang, X. Xu, Y. Zhao, Z. Wang, C. Wu, D. Pan, Z. Meng, Effect of the addition of Sr modifier in different conditions on microstructure and mechanical properties of T6 treated Al−Mg2Si in-situ composite. Mater. Sci. Eng. A 721(February), 263–273 (2018). https://doi.org/10.1016/j.msea.2018.02.100

H.C. Yu, H.Y. Wang, L. Chen, M. Zha, C. Wang, C. Li, Q.C. Jiang, Spheroidization of primary Mg2Si in Al-20Mg2Si-45Cu alloy modified with Ca and Sb during T6 heat treatment process. Mater. Sci. Eng. A. 685, 31–38 (2017). https://doi.org/10.1016/j.msea.2016.12.080

A.K. Gupta, B.K. Prasad, R.K. Pajnoo, S. Das, Effects of T6 heat treatment on mechanical, abrasive and erosive-corrosive wear properties of eutectic Al–Si alloy. Trans. Nonferrous Met. Soc. China 22(5), 1041–1050 (2012). https://doi.org/10.1016/S1003-6326(11)61281-8

M. Tocci, R. Donnini, G. Angella, A. Pola, Effect of Cr and Mn addition and heat treatment on AlSi3Mg casting alloy. Mater Charact 123, 75–82 (2017). https://doi.org/10.1016/j.matchar.2016.11.022

Y. Wu, J. Zhang, H. Liao, G. Li, Y. Wu, Development of high performance near eutectic Al–Si–Mg alloy profile by micro alloying with Ti. J. Alloys Compd. 660, 141–147 (2016). https://doi.org/10.1016/j.jallcom.2015.11.083

I. Bacaicoa, P.K. Dwivedi, M. Luetje, F. Zeismann, A. Brueckner-Foit, A. Geisert, M. Fehlbier, Effect of non-equilibrium heat treatments on microstructure and tensile properties of an Al–Si–Cu alloy. Mater. Sci. Eng. A 673, 562–571 (2016). https://doi.org/10.1016/j.msea.2016.07.080

R. Chen, Q. Xu, Z. Jia, B. Liu, Precipitation behavior and hardening effects of Si-containing dispersoids in Al–7Si–Mg alloy during solution treatment. Mater. Des. 90, 1059–1068 (2016). https://doi.org/10.1016/j.matdes.2015.11.069

J. Pezda, The effect of the T6 heat treatment on hardness and microstructure of the En AC-AlSi12CuNiMg Alloy. Metalurgija 53(1), 63–66 (2014)

Z. Li, C. Li, Y. Liu, L. Yu, Q. Guo, H. Li, Effect of heat treatment on microstructure and mechanical property of Al-10%Mg2Si alloy. J. Alloys Compd. 663, 16–19 (2016). https://doi.org/10.1016/j.jallcom.2015.12.128

S. Wang, K. Matsuda, T. Kawabata, T. Yamazaki, S. Ikeno, Variation of age-hardening behavior of TM-addition Al–Mg–Si alloys. J. Alloys Compd. 509(41), 9876–9883 (2011). https://doi.org/10.1016/j.jallcom.2011.07.067

H.A. Razazi, M. Paidar, O.O. Ojo, Effect of Mn and Cr on structure and mechanical properties of Al-10%Mg-0.1%Ti Alloy. Vacuum 155, 619–630 (2018). https://doi.org/10.1016/j.vacuum.2018.06.071

J. Fu, K. Cui, Effect of Mn content on the microstructure and corrosion resistance of Al–Cu–Mg–Mn alloys. J. Alloys Compd. 896, 162903 (2022). https://doi.org/10.1016/j.jallcom.2021.162903

T.M. Ribeiro, E. Catellan, A. Garcia, C.A. dos Santos, The effects of Cr addition on microstructure, hardness and tensile properties of as-cast Al-3.8wt%Cu-(Cr) alloys. J. Mater. Res. Technol. 9(3), 6620–6631 (2020). https://doi.org/10.1016/j.jmrt.2020.04.054

Y. Weng, Y. Xu, L. Ding, Z. Jia, Z. Zhang, J. Chen, M. Xie, Q. Liu, Effect of Sn contents on natural aging and precipitation hardening in Al–Mg–Si Alloys. Mater. Charact. 179(August), 111383 (2021). https://doi.org/10.1016/j.matchar.2021.111383

M. Beder, Y. Alemdag, Influence of Mg addition and T6 heat treatment on microstructure, mechanical and tribological properties of Al–12Si–3Cu based alloy. Trans. Nonferrous Met. Soc. China. 31(8), 2208–2219 (2021). https://doi.org/10.1016/S1003-6326(21)65649-2

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, D.L. Chen, Ageing Characteristics and High-Temperature Tensile Properties of Al-Si-Cu-Mg Alloys with Micro-Additions of Cr, Ti, V and Zr. Mater. Sci. Eng. A 652, 353–364 (2016). https://doi.org/10.1016/j.msea.2015.11.049

M. Tocci, A. Pola, G. Angella, R. Donnini, V.G.M. La, Dispersion hardening of an AlSi3Mg alloy with Cr and Mn addition. Mater. Today Proc. 10, 319–326 (2019). https://doi.org/10.1016/j.matpr.2018.10.412

H. Zhan, B. Hu, Analyzing the microstructural evolution and hardening response of an Al–Si–Mg casting alloy with Cr addition. Mater. Charact. 142(May), 602–612 (2018). https://doi.org/10.1016/j.matchar.2018.06.026

O. Prach, O. Trudonoshyn, P. Randelzhofer, Körner, K. Durst, Multi-alloying effect of Sc, Zr, Cr on the Al–Mg–Si–Mn high-pressure die casting alloys. Mater. Charact. 168, 110537 (2020). https://doi.org/10.1016/j.matchar.2020.110537

O. Prach, O. Trudonoshyn, P. Randelzhofer, Körner, K. Durst, Effect of Zr, Cr and Sc on the Al–Mg–Si–Mn high-pressure die casting alloys. Mater. Sci. Eng. A. 759, 603–612 (2019). https://doi.org/10.1016/j.msea.2019.05.038

O. Trudonoshyn, O. Prach, P. Randelzhofer, K. Durst, Körner, Heat treatment of the new high-strength high-ductility Al–Mg–Si–Mn Alloys with Sc Zr and Cr additions. Materialia (2021). https://doi.org/10.1016/j.mtla.2020.100981

Z. An, W. Yang, H. Zhan, B. Hu, Q. Wang, S. Matsumura, G. Sha, On the strengthening effect of Al–Cr–Si Dispersoid in an Al–Si–Mg–Cu casting alloy with Cr addition. Mater Charact 166(June), 110457 (2020). https://doi.org/10.1016/j.matchar.2020.110457

E.A. Brandes, G.B. Brook, Smithells metals reference book (Seventh; Butterworth-Heinemann, Boston, 1992)

Ü. Bayram, Directional solidification of Al–Si–Ti irregular ternary eutectic alloy and thermophysical properties. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. (2022). https://doi.org/10.1007/s11663-022-02648-6

U. Böyük, Physical and mechanical properties of Al–Si–Ni eutectic alloy. Met. Mater. Int. 18(6), 933–938 (2012). https://doi.org/10.1007/s12540-012-6004-5

O. Kahveci, E. Çadirli, M. Ari, H. Tecer, M. Gündüz, Measurement and prediction of the thermal and electrical conductivity of Al-Zr overhead line conductors at elevated temperatures. Mater. Res. (2019). https://doi.org/10.1590/1980-5373-MR-2018-0513

D.R. Lide, CRC handbook of chemistry and physics. J. Mol. Struct. (2005). https://doi.org/10.1016/0022-2860(92)85083-s

R. Brandt, G. Neuer, Electrical resistivity and thermal conductivity of pure aluminum and aluminum alloys up to and above the melting temperature. Int. J. Thermophys. 28(5), 1429–1446 (2007). https://doi.org/10.1007/s10765-006-0144-0

A. Ben Abdellah, B. Grosdidier, S.M. Osman, S.M. Mujibur Rahman, M. Mayoufi, J. Ataati, J.G. Gasser, Spin-state dependence of electrical resistivity and thermoelectric power of molten Al-Mn alloys: experiment and theory. J. Alloys Compd. 658, 1010–1019 (2016). https://doi.org/10.1016/j.jallcom.2015.10.271

Y. Kaygısız, N. Maraşlı, Hardness and electrical resistivity of Al–13 Wt % Mg2Si pseudoeutectic alloy. Russ. J. Non-Ferrous Met. 58(1), 15–21 (2017). https://doi.org/10.3103/S1067821217010060

Acknowledgements

This project was supported by Necmettin Erbakan University Scientific Research Project Unit, Contract No: 161226001. The authors are obliged to Necmettin Erbakan University for their financial contribution.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaygısız, Y., Palta, Ç., Kaymaz, T.Ç. et al. The Effect of Mn Addition and Heat Treatment on the Microstructure, Mechanical, and Thermophysical Properties of Al-Si-Mg Eutectic Alloy. Inter Metalcast (2023). https://doi.org/10.1007/s40962-023-01165-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40962-023-01165-9