Abstract

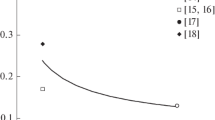

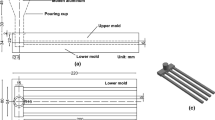

Graphite mold casting is a promising technique owing to its ability to provide high cooling rates and suitability for many types of alloys. The fluidity of A356 aluminum and AZ91 magnesium alloys cast into graphite molds was determined at casting temperatures of 670 °C–810 °C. As expected, the fluidity of AZ91 was lower than that of A356. The critical solid fractions for A356 aluminum and AZ91 magnesium alloys were determined by comparing simulated spiral fluidity test lengths with those obtained experimentally. For graphite mold casting, the critical solid fractions for A356 and AZ91 alloys were in the range of 0.12–0.15 and 0.13–0.17, respectively.

Similar content being viewed by others

References

V.E. Bazhenov, Yu.V. Tselovalnik, A.V. Koltygin, V.D. Belov, Submitted to Int. J. Metalcast.

J. Major, M. Hartlieb, Int. J. Metalcast. 3, 43 (2009)

S. O’Connor, Adv. Mater. Process. 166, 29 (2008)

S. O’Connor, AMMTIAC Quart. 2, 3 (2007)

L. Jia, D. Xu, M. Li, J. Guo, H. Fu, Met. Mater. Int. 18, 55 (2012)

V. Zanchuk, Adv. Mater. Process. 162, 66 (2004)

V. Zanchuk, Die Cast Eng. 1, 38 (2006)

L. Wang, H. Yan, J. Teng, X. Liu, X. Wang, Y. Su, J. Guo, J. Mater. Res. Tech. (in press). https://doi.org/10.1016/j.jmrt.2020.02.071. (2020)

G. Baumeister, D. Buqezi-Ahmeti, J. Glaser, H.-J. Ritzhaupt-Kleissl, Microsyst. Technol. 17, 289 (2011)

W.C. Chen, F.Y. Teng, C.C. Hung, Mater. Sci. Eng. C 35, 231 (2014)

A.Y.C. Nee, Handbook of Manufacturing Engineering and Technology (Springer, London, 2015)

H. Huang, Y.X. Wang, P.H. Fu, L.M. Peng, H.Y. Jiang, W.Y. Xu, Int. J. Cast Met. Res. 26, 213 (2013)

M. Sabatino, L. Arnberg, D. Apelian, Int. J. Metalcast. 2, 17 (2008)

T.O. Mbuya, Trans. Am. Foundry. Soc. 114, 163 (2006)

M. Di Sabatino, L. Arnberg, Metall. Sci. Technol. 22, 9 (2004)

K.R. Ravi, R.M. Pillai, K.R. Amaranathan, B.C. Pai, M. Chakraborty, J. Alloys Compd. 456, 201 (2008)

Y. Motoyama, H. Tokunaga, M. Yoshida, T. Maruyama, T. Okane, J. Mater. Process. Tech. 276, 116394 (2020)

J. Jakumeit, E. Subasic, M. Bünck, Shape Casting: 5th International Symposium 2014 (Wiley, San Diego, 2014), pp. 253–260

V.E. Bazhenov, A.V. Petrova, A.V. Koltygin, Int. J. Metalcast. 12, 514 (2018)

M.A.A. Khan, A.K. Sheikh, Int. J. Simul. Model. 17, 197 (2018)

ESI Group, ProCAST 2010.0 User’s Manual (ESI Group, 2010), https://myesi.esi-group.com/system/files/documentation/ProCAST/2010/ProCAST_20100_UM.pdf. Accessed 1 August 2019

L. Yang, L.H. Chai, Y.F. Liang, Y.W. Zhang, C.L. Bao, S.B. Liu, J.P. Lin, Intermetallics 66, 149 (2015)

S.-L. Lu, F.-R. Xiao, Z.-H. Guo, L.-J. Wang, H.-Y. Li, B. Liao, Appl. Therm. Eng. 93, 518 (2016)

J.A. Dantzig, M. Rappaz, Solidification (EPFL Press, Lausanne, 2009), pp. 105–151

E.I. Zhmurikov, I.V. Savchenko, S.V. Stankus, O.S. Yatsuk, L.B. Tecchio, Nucl. Instrum. Methods Phys. Res. Sect. A 674, 79 (2012)

G. Palumbo, V. Piglionico, A. Piccininni, P. Guglielmi, D. Sorgente, L. Tricarico, Appl. Therm. Eng. 78, 682 (2015)

V.E. Bazhenov, A.V. Koltygin, Yu.V. Tselovalnik, Russ. J. Non-Ferr. Met. 57, 686 (2016)

V.E. Bazhenov, A.V. Petrova, A.V. Koltygin, Yu.V. Tselonalnik, Tsvetnye Metally 2017, 89 (2017)

W.P. Goss, R.G. Miller, Proceedings of Thermal Performance of the Exterior Envelopes of Buildings (ASHRAE, New York, 1992), pp. 193–203

A.S.M. Handbook, Properties and selection: Nonferrous alloys and special-purpose materials, vol. 2, 10th edn. (ASM International, Materials Park, 2002), pp. 624–1546

A.K. Dahle, P.A. Tøndel, C.J. Paradies, L. Arnberg, Metall. Mater. Trans. A 27, 2305 (1996)

A.K. Dahle, L. Arnberg, Acta Mater. 45, 547 (1997)

N.L.M. Veldman, A.K. Dahle, D.H. StJohn, L. Arnberg, Metall. Mater. Trans. A 32, 147 (2001)

L. Arnberg, G. Chai, L. Backerud, Mater. Sci. Eng., A 173, 101 (1993)

M. Król, T. Tański, G. Matula, P. Snopiński, A. Tomiczek, Arch. Metall. Mater. 60, 2993 (2015)

F. Yavari, S.G. Shabestari, Int. J. Cast Met. Res. 32, 85 (2019)

Acknowledgements

The reported study was funded by RFBR, Project Number 19-38-90003.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors report no potential conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bazhenov, V.E., Petrova, A.V., Rizhsky, A.A. et al. Simulation and Experimental Validation of A356 and AZ91 Alloy Fluidity in a Graphite Mold. Inter Metalcast 15, 319–325 (2021). https://doi.org/10.1007/s40962-020-00468-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-020-00468-5