Abstract

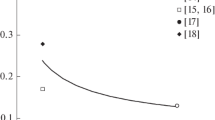

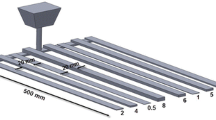

The basic parameters for the high-precision simulation of misrun formation in castings are the interface heat transfer coefficient (IHTC) between the casting and the mold and the critical solid fraction (f crS ) at which the alloy flow in the mold is choked off. The values for IHTC were obtained by comparing the simulated spiral lengths at different IHTC values with those obtained from experimental results. The IHTC values above the liquidus temperature (IHTCL = 1200 W m−2 K−1) and below the solidus temperature (IHTCS = 600 W m−2 K−1), as well as the critical solid fraction (f crS = 0.1–0.15), were determined. The obtained values of IHTCL, IHTCS, and f crS were used to simulate the casting process of 356.0 aluminum alloy into sand molds. Comparison of the misruns obtained in the cylindrical casting with misruns predicted by the simulation confirmed the accuracy of the IHTCL and IHTCS values obtained using the spiral test and allowed the value of the critical solid fraction (f crS = 0.1) to be defined more accurately.

Similar content being viewed by others

References

M. Di Sabatino, L. Arnberg, D. Apelian, Int. J. Metalcast. 2, 17 (2008)

J. Major, M. Hartlieb, Int. J. Metalcast. 3, 43 (2009)

S.-Y. Sung, Y.-J. Kim, Intermetallics 15, 468 (2007)

J. Jakumeit, E. Subasic, M. Bünck, Shape Casting: 5th International Symposium 2014 (Wiley, San Diego, 2014), pp. 253–260

N.J. Humphreys, D. McBride, D.M. Shevchenko, T.N. Croft, P. Withey, N.R. Green, M. Cross, Appl. Math. Modell. 37, 7633 (2013)

T.O. Mbuya, Trans. Am. Foundry Soc. 114, 163 (2006)

M. Di Sabatino, L. Arnberg, Metall. Sci. Technol. 22, 9 (2004)

K.R. Ravi, R.M. Pillai, K.R. Amaranathan, B.C. Pai, M. Chakraborty, J. Alloys Compd. 456, 201 (2008)

A.K. Dahle, P.A. Tøndel, C.J. Paradies, L. Arnberg, Metall. Mater. Trans. A 27, 2305 (1996)

A.K. Dahle, L. Arnberg, Acta Mater. 45, 547 (1997)

N.L. Veldman, A.K. Dahle, D.H. StJohn, L. Arnberg, Metall. Mater. Trans. A 32, 147 (2001)

L. Arnberg, G. Chai, L. Backerud, Mater. Sci. Eng. A 173, 101 (1993)

O. Cabrera, M. Ramírez, B. Campillo, C. González-Rivera, Mater. Manuf. Process. 23, 46 (2007)

D. Brabazon, D.J. Browne, A.J. Carr, Mater. Sci. Eng. A 356, 69 (2003)

J.C. Baez, C. Gonzalez, M.R. Chavez, M. Castro, J. Juarez, J. Mater. Process. Technol. 153–154, 531 (2004)

R. Rajaraman, R. Velraj, Heat Mass Transf. 44, 1025 (2008)

L. Chen, Y. Wang, L. Peng, P. Fu, H. Jiang, Exp. Therm. Fluid Sci. 54, 196 (2014)

J. Kang, X. Hao, G. Nie, H. Long, B. Liu, J. Mater. Process. Technol. 215, 278 (2015)

K. Kubo, R.D. Pehlke, Metall. Trans. B 16, 359 (1985)

S.N. Kulkarni, D.K. Radhakrishna, Mater. Sci. Pol. 29, 135 (2011)

R.K. Nayak, S. Sundarraj, Metall. Mater. Trans. B 41, 151 (2010)

M. Di Sabatino, L. Arnberg, F. Bonollo, Metall. Sci. Technol. 23, 3 (2005)

ESI Group, ProCAST 2010.0 User’s Manual (ESI Group, 2010), http://myesi.esi-group.com/system/files/documentation/ProCAST/2010/ProCAST_20100_UM.pdf. Accessed 8 Oct 2017

L. Yang, L.H. Chai, Y.F. Liang, Y.W. Zhang, C.L. Bao, S.B. Liu, J.P. Lin, Intermetallics 66, 149 (2015)

S.-L. Lu, F.-R. Xiao, Z.-H. Guo, L.-J. Wang, H.-Y. Li, B. Liao, Appl. Therm. Eng. 93, 518 (2016)

J.A. Dantzig, M. Rappaz, Solidification (EPFL Press, Lausanne, 2009), pp. 105–151

V.E. Bazhenov, A.V. Koltygin, Yu.V. Tselovalnik, Russ. J. Non Ferr. Met. 57, 686 (2016)

T. Midea, J.V. Shah, AFS Trans. 110, 121 (2002)

G. Palumbo, V. Piglionico, A. Piccininni, P. Guglielmi, D. Sorgente, L. Tricarico, Appl. Therm. Eng. 78, 682 (2015)

E.I. Zhmurikov, I.V. Savchenko, S.V. Stankus, O.S. Yatsuk, L.B. Tecchio, Nucl. Instrum. Methods Phys. Res., Sect. A 674, 79 (2012)

V.E. Bazhenov, A.V. Koltygin, Yu.V. Tselovalnik, A.V. Sannikov, Russ. J. Non Ferr. Met. 58, 114 (2017)

Acknowledgements

The work was undertaken with support from a Grant of the President of the Russian Federation to young scientists and postgraduates who are carrying out scientific investigations and developments in the priority directions of the Russian Federation’s economy modernization (2016–2018 contest).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bazhenov, V.E., Petrova, A.V. & Koltygin, A.V. Simulation of Fluidity and Misrun Prediction for the Casting of 356.0 Aluminum Alloy into Sand Molds. Inter Metalcast 12, 514–522 (2018). https://doi.org/10.1007/s40962-017-0188-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-017-0188-x