Abstract

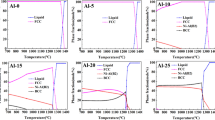

A high-entropy dual-phase AlTiVCoNi alloy with a low density of ∼6.24 g cm−3 is developed, and it consists of a hierarchical structure, including an ordered L21 phase, a disordered body-centered-cubic (BCC) solid-solution phase, and nano-sized L21 precipitates embedded in the BCC phase. It is found that this new alloy shows phase stability after the heat treatment at 1200°C for 24 h, and the compressive yield strength of this annealed alloy is approximately equal to that of the as-cast condition, ∼1.6 GPa. This alloy displays an exceptional compressive strength at room temperature and at 600°C, with the specific yield strengths of ∼261 and ∼210 MPa g−1 cm3, respectively. The semi-coherent interface of the L21 and the BCC phases makes the alloy phase stable and regulates the work-hardening mechanism. Local dynamic-recrystallization behavior and grain evolution are observed in the as-prepared alloy during compression at 800 and 1000°C, which results in the high-temperature softening. This alloy with a muti-phase hierarchical structure would provide a new paradigm for the development of next-generation low-density, high-entropy structural materials for high-temperature applications.

摘要

本文研究了一种新型低密度(~6.24 g cm−3)双相AlTiVCoNi高熵合金, 其组织结构由有序L21 高熵金属间化合物、无序体心立方结构和纳米L21 相多层次结构构成. 该合金在1200°C + 24 h热处理下未发生相结构转变, 在此条件下具有优异的高温相结构稳定性, 其铸态和热处理态的压缩屈服强度相当, 达到~1.6 GPa. 另外, 该合金在室温和600°C条件下表现出了优异的强塑性匹配和优异的比屈服强度, 分别达到了约261和210 MPa g−1cm3. 该合金的超高强度主要源于有序L21 相与体心立方相的半共格界面导致的一种强相结构稳定性和多层次结构的复合强化机制. 该合金在800和1000°C压缩过程中出现了动态再结晶软化,使得其高温强度有所降低. 这种“具有半共格界面L21 + 体心立方+ 纳米L21颗粒”的多层次结构设计为开发新型低密度耐高温高熵合金提供了一种新设计思路.

Similar content being viewed by others

References

Yeh JW, Chen SK, Lin SJ, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv Eng Mater, 2004, 6: 299–303

Yao Y, Huang Z, Xie P, et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science, 2018, 359: 1489–1494

Lei Z, Liu X, Wu Y, et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature, 2018, 563: 546–550

Shi P, Li R, Li Y, et al. Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys. Science, 2021, 373: 912–918

Pan Q, Zhang L, Feng R, et al. Gradient cell-structured high-entropy alloy with exceptional strength and ductility. Science, 2021, 374: 984–989

Lu Y, Huang H, Gao X, et al. A promising new class of irradiation tolerant materials: Ti2ZrHfV0.5Mo0.2 high-entropy alloy. J Mater Sci Tech, 2019, 35: 369–373

Wu Y, Liaw P, Zhang Y. Preparation of bulk TiZrNbMoV and NbTiAlTaV high-entropy alloys by powder sintering. Metals, 2021, 11: 1748

Feng R, Zhang C, Gao MC, et al. High-throughput design of high-performance lightweight high-entropy alloys. Nat Commun, 2021, 12: 4329

Wang M, Lu Y, Wang T, et al. A novel bulk eutectic high-entropy alloy with outstanding as-cast specific yield strengths at elevated temperatures. Scripta Mater, 2021, 204: 114132

Varma SK, Sanchez F, Moncayo S, et al. Static and cyclic oxidation of Nb-Cr-V-W-Ta high entropy alloy in air from 600 to 1400°C. J Mater Sci Tech, 2020, 38: 189–196

Zhang W, Liaw PK, Zhang Y. Science and technology in high-entropy alloys. Sci China Mater, 2018, 61: 2–22

Zhang Y, Zuo TT, Tang Z, et al. Microstructures and properties of high-entropy alloys. Prog Mater Sci, 2014, 61: 1–93

Tsai MH, Yeh JW. High-entropy alloys: A critical review. Mater Res Lett, 2014, 2: 107–123

China-Aeronautical-Materials-Handbook-Editorial-Board. China Aeronautical Materials Handbook Second edition -Volume (2). Beijing, China: Standards Press of China, 2001, 874

Li R, Gao JC, Fan K. Microstructure and mechanical properties of MgMnAlZnCu high entropy alloy cooling in three conditions. MSF, 2011, 686: 235–241

Li R, Gao JC, Fan K. Study to microstructure and mechanical properties of Mg containing high entropy alloys. MSF, 2010, 650: 265–271

Yang X, Chen SY, Cotton JD, et al. Phase stability of low-density, multiprincipal component alloys containing aluminum, magnesium, and lithium. JOM, 2014, 66: 2009–2020

Shao L, Zhang T, Li L, et al. A low-cost lightweight entropic alloy with high strength. J Materi Eng Perform, 2018, 27: 6648–6656

Li Y, Li R, Zhang Y. Effects of Si addition on microstructure, properties and serration behaviors of lightweight Al-Mg-Zn-Cu medium-entropy alloys. Res Appl Mater Sci, 2019, 1: 13

Li R, Wang Z, Guo Z, et al. Graded microstructures of Al-Li-Mg-Zn-Cu entropic alloys under supergravity. Sci China Mater, 2019, 62: 736–744

Li H, Yang C, Fu J, et al. Nano-amorphous-crystalline dual-phase design of Al80Li5Mg5Zn5Cu5 multicomponent alloy. Sci China Mater, 2022, 65: 1671–1678

Youssef KM, Zaddach AJ, Niu C, et al. A novel low-density, high-hardness, high-entropy alloy with close-packed single-phase nano-crystalline structures. Mater Res Lett, 2015, 3: 95–99

Tseng KK, Yang YC, Juan CC, et al. A light-weight high-entropy alloy Al20Be20Fe10Si15Ti35. Sci China Technol Sci, 2018, 61: 184–188

Senkov ON, Wilks GB, Scott JM, et al. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics, 2011, 19: 698–706

Feng R, Feng B, Gao MC, et al. Superior high-temperature strength in a supersaturated refractory high-entropy alloy. Adv Mater, 2021, 33: 2102401

Karthick G, Raman L, Murty BS. Phase evolution and mechanical properties of novel nanocrystalline Y2(TiZrHfMoV)2O7 high entropy pyrochlore. J Mater Sci Tech, 2021, 82: 214–226

Stepanov ND, Shaysultanov DG, Salishchev GA, et al. Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy. Mater Lett, 2015, 142: 153–155

Stepanov ND, Yurchenko NY, Sokolovsky VS, et al. An AlNbTiVZr0.5 high-entropy alloy combining high specific strength and good ductility. Mater Lett, 2015, 161: 136–139

Xu ZQ, Ma ZL, Wang M, et al. Design of novel low-density refractory high entropy alloys for high-temperature applications. Mater Sci Eng-A, 2019, 755: 318–322

Qiu Y, Hu YJ, Taylor A, et al. A lightweight single-phase AlTiVCr compositionally complex alloy. Acta Mater, 2017, 123: 115–124

Qiu Y, Thomas S, Gibson MA, et al. Microstructure and corrosion properties of the low-density single-phase compositionally complex alloy AlTiVCr. Corrosion Sci, 2018, 133: 386–396

Li Y, Liaw PK, Zhang Y. Microstructures and properties of the low-density Al15Zr40Ti28Nb12M(Cr,Mo,Si)5 high-entropy alloys. Metals, 2022, 12: 496

Tan XR, Zhao RF, Ren B, et al. Effects of hot pressing temperature on microstructure, hardness and corrosion resistance of Al2NbTi3V2Zr high-entropy alloy. Mater Sci Tech, 2016, 32: 1582–1591

Yao H, Liu Y, Sun X, et al. Microstructure and mechanical properties of Ti3V2NbAlxNiy low-density refractory multielement alloys. Intermetallics, 2021, 133: 107187

Pang J, Zhang H, Zhang L, et al. Ductile Ti1.5ZrNbAl0.3 refractory high entropy alloy with high specific strength. Mater Lett, 2021, 290: 129428

Senkov ON, Senkova SV, Woodward C, et al. Low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system: Microstructure and phase analysis Acta Mater, 2013, 61: 1545–1557

Senkov ON, Senkova SV, Miracle DB, et al. Mechanical properties of low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system Mater Sci Eng-A, 2013, 565: 51–62

Feng R, Gao M, Lee C, et al. Design of light-weight high-entropy alloys Entropy, 2016, 18: 333

Feng R, Gao MC, Zhang C, et al. Phase stability and transformation in a light-weight high-entropy alloy. Acta Mater, 2018, 146: 280–293

Xu J, Xia Y, Li Z, et al. Multi-physics instrument: Total scattering neutron time-of-flight diffractometer at China Spallation Neutron Source. Nucl Instruments Methods Phys Res Sect A-Accelerators Spectrometers Detectors Associated Equipment, 2021, 1013: 165642

Packard JC. Archimedes principle. School Sci Math, 1929, 29: 969–970

Yan XH, Liaw PK, Zhang Y. Order and disorder in amorphous and high-entropy materials. Metall Mater Trans A, 2021, 52: 2111–2122

Cao P, Ni X, Tian F, et al. Ab initio study of AlxMoNbTiV high-entropy alloys. J Phys-Condens Matter, 2015, 27: 075401

Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans, 2005, 46: 2817–2829

Zhang Y, Zhou Y, Lin J, et al. Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater, 2008, 10: 534–538

Guo S, Ng C, Lu J, et al. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J Appl Phys, 2011, 109: 103505

Yang X, Zhang Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater Chem Phys, 2012, 132: 233–238

Ye YF, Wang Q, Lu J, et al. The generalized thermodynamic rule for phase selection in multicomponent alloys. Intermetallics, 2015, 59: 75–80

Ye YF, Wang Q, Lu J, et al. Design of high entropy alloys: A single-parameter thermodynamic rule. Scripta Mater, 2015, 104: 53–55

Nagase T, Rack PD, Noh JH, et al. In-situ TEM observation of structural changes in nano-crystalline CoCrCuFeNi multicomponent high-entropy alloy (HEA) under fast electron irradiation by high voltage electron microscopy (HVEM). Intermetallics, 2015, 59: 32–42

Yeh JW. Recent progress in high-entropy alloys. Ann Chim Sci Mat, 2006, 31: 633–648

Yan X, Zhang Y. Functional properties and promising applications of high entropy alloys. Scripta Mater, 2020, 187: 188–193

Yang T, Zhao YL, Tong Y, et al. Multicomponent intermetallic nano-particles and superb mechanical behaviors of complex alloys. Science, 2018, 362: 933–937

Lütjering G, Williams JC. Titanium (2nd edition). Berlin, Germany: Springer-Verlag Berlin Heidelberg, 2007, 449

Yao K, Liu L, Ren J, et al. High-entropy intermetallic compound with ultra-high strength and thermal stability. Scripta Mater, 2021, 194: 113674

Zhang Y, Liu JP, Chen SY, et al. Serration and noise behaviors in materials. Prog Mater Sci, 2017, 90: 358–460

Vegard L. Die konstitution der mischkristalle und die raumfüllung der atome. Z Physik, 1921, 5: 17–26

Stepanov ND, Yurchenko NY, Panina ES, et al. Precipitation-strengthened refractory Al0.5CrNbTi2V0.5 high entropy alloy. Mater Lett, 2017, 188: 162–164

Steingrimsson B, Fan X, Yang X, et al. Predicting temperature-dependent ultimate strengths of body-centered-cubic (BCC) high-entropy alloys npj Comput Mater, 2021, 7: 152

Jiang S, Wang H, Wu Y, et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation Nature, 2017, 544: 460–464

Acknowledgements

Zhang Y appreciated the supports from the Fundamental Research Funds for the Central Universities (FRF-MP-19-013), Guangdong Basic and Applied Basic Research Foundation (2019B1515120020), the State Key Laboratory for Advanced Metals and Materials, the University of Science and Technology Beijing (2020Z-08), and the Funds for Creative Research Groups of China (51921001) Liao WB thanked the National Natural Science Foundation of China (51801128), and Guangdong Basic and Applied Basic Research Foundation (2021A1515012278 and 2022A1515010288) He Z appreciated the supports from the National Natural Science Foundation of China (51871015 and 52171151) Liaw PK appreciated the supports from the National Science Foundation (DMR-1611180 and 1809640) with program directors, Drs J Yang, G. Shiflet, and D. Farkas and the US Army Research Office (W911NF-13-1-0438 and W911NF-19-2-0049) with program managers, Drs. M.P. Bakas, S.N. Mathaudhu, and D.M. Stepp.

Author information

Authors and Affiliations

Contributions

Li Y conducted the experiments and wrote the draft; Liao WB and Zhang Y conceived the idea and directed the whole project. Chen H, Brechtl J, Song W, Yin W, He Z, and Liaw PK provided valuable suggestions. All authors contributed to the general discussion.

Corresponding authors

Additional information

Conflict of interest

The authors declare that they have no conflict of interest.

Supplementary information

Calculation details and supporting data are available in the online version of the paper.

Yasong Li is a PhD student at the State Key Laboratory for Advanced Metals and Materials, University of Science & Technology Beijing (USTB), under Prof. Yong Zhang’s supervision. His research interest is on high-entropy alloys.

Wei-Bing Liao received his PhD degree in materials science and engineering from USTB in 2013. He did postdoctoral work at Peking University from 2013 to 2015, and the City University of Hong Kong from 2015 to 2017. Then, he jointed Shenzhen University as an assistant professor in 2017. His research interest focuses on bulk-metallic glasses and high-entropy alloys.

Yong Zhang has been a professor of materials science at the USTB since 2004. He has published over 200 papers and authored a book entitled “High-Entropy Materials, A Brief Introduction” by Springer-Nature publisher. He proposed a parameter to evaluate the configurational entropy effect over the enthalpy effect in the liquid state. It has been verified to be effective in predicting the phase formation for the multicomponent materials.

Peter K. Liaw obtained his BSc degree in physics from Tsing Hua University, Taiwan, and his PhD degree in materials science and engineering from the Northwestern University, in 1980. After working at Westinghouse Research and Development (R&D) Center for thirteen years, he joined the faculty and became an Endowed Ivan Racheff Chair of Excellence at the Department of Materials Science and Engineering, The University of Tennessee (UT), Knoxville in March 1993. He is working in the areas of fatigue, fracture, nondestructive evaluation, and life-prediction methodologies of structural alloys and composites.

Rights and permissions

About this article

Cite this article

Li, Y., Liao, WB., Chen, H. et al. A low-density high-entropy dual-phase alloy with hierarchical structure and exceptional specific yield strength. Sci. China Mater. 66, 780–792 (2023). https://doi.org/10.1007/s40843-022-2178-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-022-2178-x