Abstract

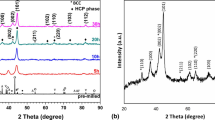

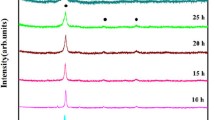

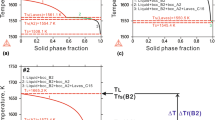

In the present investigation, a newly designed composition of equiatomic AlCrFeCoNiZn high-entropy alloy (HEA) has been synthesized by mechanical alloying. The milled powder after 30 h exhibited the formation of a single solid solution phase of BCC crystal structure with lattice parameter, a = 2.87 ± 0.02 Å. Decomposition of the single-phase BCC structure into the two-phase, tetragonal (Cr–Co)-based σ phase (a = 8.81 Å, c = 4.56 Å)- and L12 (a = 3.59 ± 0.02 Å)-type intermetallics was observed at temperature of ~ 800 °C (1073 K). However, after heat treatment of the 30 h milled powder at the temperatures of 300 °C (573 K) and 600 °C (873 K), similar type of phases was also noticed to coexist along with B2 (a = 2.87 ± 0.03 Å)-type phase. This behaviour of the alloy confirms the diffusive nature of the phase transformation. The consolidated bulk alloy exhibited similar type of phases after sintering at 950 °C (1223 K).

Similar content being viewed by others

References

Ranganathan S, Curr Sci85 (2003) 1404.

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, and Chang S Y, Adv Eng Mater6 (2004) 299.

Cantor B, Chang I T H, Knight P, and Vincent A J B, Mater Sci Eng A375–377 (2004) 213.

Ye Y F, Wang Q, Lu J, Liu C T, and Yang Y, Mater Today19 (2016) 349.

Mukhopadhyay N K, Curr Sci109 (2015) 665.

Tsai M H, and Yeh J W, Mater Res Lett2 (2014) 107.

Otto F, Yang Y, Bei H, and George E P, Acta Mater61 (2013) 2628.

Wang Y P, Li B S, and Fu H Z, Adv Eng Mater11 (2009) 641.

Yao M J, Pradeep K G, Tasan C C, and Raabe D, Scr Mater72–73 (2014) 5.

Yadav T P, Mukhopadhyay S, Mishra S S, Mukhopadhyay N K, and Srivastava O N, Philos Mag Lett97 (2017) 494.

Pickering E J, and Jones N G, Int Mater Rev61 (2016) 183.

Senkov O N, and Miracle D B, J Alloys Compd658 (2016) 603.

Sharma A S, Yadav S, Biswas K, and Basu B, Mater Sci Eng R 131 (2018) 1.

Zhang K B, Fu Z Y, Zhang J Y, Wang W M, Wang H, Wang Y C, Zhang Q J, and Shi J, Mater Sci Eng A508 (2009) 214.

Bhadeshia H K D H, Mater Sci Technol31 (2015) 1139.

Shivam V, Shadangi Y, Basu J, and Mukhopadhyay N K, J Mater Res35 (2019) 787.

Zhang Y, Ting T, Tang Z, Gao M C, Dahmen K A, Liaw P K, and Ping Z, Prog Mater Sci61 (2014) 1.

Koch C C, Mater Res Lett32 (2017) 3435.

Varalakshmi S, Kamaraj M, and Murty B S, J Alloys Compd460 (2008) 253.

Suryanarayana C, Prog Mater Sci46 (2001) 1.

Raviathul Basariya M, Srivastava V C, and Mukhopadhyay N K, Mater Des64 (2014) 542.

Shadangi Y, Shivam V, Singh M K, Chattopadhyay K, Basu J, and Mukhopadhyay N K, J Alloys Compd797 (2019) 1280.

Varalakshmi S, Kamaraj M, and Murty B S, Metall Mater Trans A Phys Metall Mater Sci41 (2010) 2703.

Vaidya M, Prasad A, Parakh A, and Murty B S, Mater Des126 (2017) 37.

Shivam V, Basu J, Pandey V K, Shadangi Y, and Mukhopadhyay N K, Adv Powder Technol29 (2018) 2221.

Shivam V, Basu J, Shadangi Y, Singh M K, and Mukhopadhyay N K, J Alloys Compd757 (2018) 87.

Thurston K V S, Gludovatz B, Hohenwarter A, Laplanche G, George E P, and Ritchie R O, Intermetallics88 (2017) 65.

Borkar T, Gwalani B, Choudhuri D, Mikler C V, Yannetta C J, Chen X, Ramanujan R V, Styles M J, Gibson M A, and Banerjee R, Acta Mater116 (2016) 63.

Praveen S, Murty B S, and Kottada R S, Mater Sci Eng A534 (2012) 83.

Suryanarayana C, Ivanov E, and Boldyrev V, Mater Sci Eng A304 (2001) 151.

Basariya M R, Srivastava V C, and Mukhopadhyay N K, Philos Mag96 (2016) 2445.

Miracle D B, and Senkov O N, Acta Mater122 (2017) 448.

Guo S, Hu Q, Ng C, and Liu C T, Intermetallics41 (2013) 96.

Yang X, and Zhang Y, Mater Chem Phys132 (2012) 233.

Zhang Y, Zhou Y J, Lin J P, Chen G L, and Liaw P K, Adv Eng Mater10 (2008) 534.

Miedema A R, de Châtel P F, and de Boer F R Phys B100 (1980) 1.

Guo S, and Liu C T, Prog Nat Sci Mater Int21 (2011) 433.

Dwivedi A, Koch C C, and Rajulapati K V, Mater Lett183 (2016) 44.

Jiang L I, JOM, (2020).

Chen Y L, Hu Y H, Hsieh C A, Yeh J W, and Chen S K, J Alloys Compd 481 (2009) 768.

Mohanty S, Maity T N, Mukhopadhyay S, Sarkar S, Gurao N P, Bhowmick S, and Biswas K, Mater Sci Eng A679 (2017) 299.

Acknowledgements

The authors would like to thank Dr. Joysurya Basu, Dr. Manish Kumar Singh, Mr. Vivek Kumar Pandey and Mr. Yagnesh Shadangi for many useful discussions during the course of this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shivam, V., Sanjana, V. & Mukhopadhyay, N.K. Phase Evolution and Thermal Stability of Mechanically Alloyed AlCrFeCoNiZn High-Entropy Alloy. Trans Indian Inst Met 73, 821–830 (2020). https://doi.org/10.1007/s12666-020-01892-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01892-1