Abstract

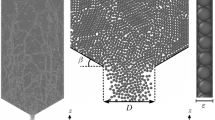

The stable discharge of particles through the hopper plays a key role in many industrial applications. In order to investigate the discharge characteristics of binary particles in a rectangular hopper with an inclined bottom, the discrete element method (DEM) was used to simulate the discharge process. The accuracy of DEM was validated by comparing calculated and experimental values. The influences of geometric parameters (hopper width, orifice width, and hopper angle) and particle parameters (friction coefficient between particles, friction coefficient between particles and wall, fine particle mass fraction, and particle size ratio) on the discharge were studied. Some interesting results have been found that the effect of hopper width on discharge is minimal. The mass discharge rate is linearly related to the 3/2 power of orifice width, and it can be predicted by the modified Beverloo correlation which developed for a rectangular hopper with flat bottom. The mass discharge rate increases exponentially with the decrease in hopper angle, which is different from that of monosized particles. The mass discharge rate is more sensitive to low friction coefficient, and the friction coefficient between particles plays a leading role. Fine particles can promote the discharge process, and this effect is enhanced as particle size ratio increases.

Similar content being viewed by others

References

Li Y, Xu Y, Jiang S (2009) DEM simulations and experiments of pebble flow with monosized spheres. Powder Technol 193(3):312–318. https://doi.org/10.1016/j.powtec.2009.03.009

Ketterhagen WR, Hancock BC (2010) Optimizing the design of eccentric feed hoppers for tablet presses using DEM. Comput Chem Eng 34(7):1072–1081. https://doi.org/10.1016/j.compchemeng.2010.04.016

Tao H, Jin B, Zhong W, Wang X, Ren B, Zhang Y, Xiao R (2010) Discrete element method modeling of non-spherical granular flow in rectangular hopper. Chem Eng Process 49(2):151–158. https://doi.org/10.1016/j.cep.2010.01.006

Yu Y, Saxén H (2011) Discrete element method simulation of properties of a 3D conical hopper with mono-sized spheres. Adv Powder Technol 22(3):324–331. https://doi.org/10.1016/j.apt.2010.04.003

Calderón CA, Villagrán Olivares MC, Uñac RO, Vidales AM (2017) Correlations between flow rate parameters and the shape of the grains in a silo discharge. Powder Technol 320:43–50. https://doi.org/10.1016/j.powtec.2017.07.004

Johanson K (2004) Rathole stability analysis for aerated powder materials. Powder Technol 141(1):161–170. https://doi.org/10.1016/j.powtec.2004.02.004

Oldal I, Keppler I, Csizmadia B, Fenyvesi L (2012) Outflow properties of silos: the effect of arching. Adv Powder Technol 23(3):290–297. https://doi.org/10.1016/j.apt.2011.03.013

Nedderman RM, Tüzün U, Savage SB, Houlsby GT (1982) The flow of granular materials—I: discharge rates from hoppers. Chem Eng Sci 37(11):1597–1609. https://doi.org/10.1016/0009-2509(82)80029-8

Artega P, Tüzün U (1990) Flow of binary mixtures of equal-density granules in hoppers—size segregation, flowing density and discharge rates. Chem Eng Sci 45(1):205–223. https://doi.org/10.1016/0009-2509(90)87093-8

Ostendorf M, Schwedes J (2005) Application of particle image velocimetry for velocity measurements during silo discharge. Powder Technol 158(1):69–75. https://doi.org/10.1016/j.powtec.2005.04.020

Uñac RO, Vidales AM, Benegas OA, Ippolito I (2012) Experimental study of discharge rate fluctuations in a silo with different hopper geometries. Powder Technol 225:214–220. https://doi.org/10.1016/j.powtec.2012.04.013

Albaraki S, Antony SJ (2014) How does internal angle of hoppers affect granular flow? Experimental studies using digital particle image velocimetry. Powder Technol 268:253–260. https://doi.org/10.1016/j.powtec.2014.08.027

Bacchuwar S, Vidyapati V, Quan K-m, Lin C-L, Miller JD (2019) Quantitative bin flow analysis of particle discharge using X-ray radiography. Powder Technol 344:693–705. https://doi.org/10.1016/j.powtec.2018.12.028

Beverloo WA, Leniger HA, van de Velde J (1961) The flow of granular solids through orifices. Chem Eng Sci 15(3):260–269. https://doi.org/10.1016/0009-2509(61)85030-6

Brown RL, Richards JC (1965) Kinematics of the flow of dry powders and bulk solids. Rheol Acta 4(3):153–165. https://doi.org/10.1007/bf01969251

Myers M, Sellers M (1971) Chemical engineering, tripos part 2. Research Project Report, University of Cambridge

Humby S, Tüzün U, Yu AB (1998) Prediction of hopper discharge rates of binary granular mixtures. Chem Eng Sci 53(3):483–494. https://doi.org/10.1016/S0009-2509(97)00326-6

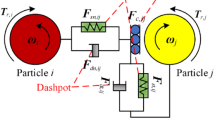

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65. https://doi.org/10.1680/geot.1979.29.1.47

Bayesteh H, Ghasempour T (2019) Role of the location and size of soluble particles in the mechanical behavior of collapsible granular soil: a DEM simulation. Comput Part Mech 6(3):327–341. https://doi.org/10.1007/s40571-018-00216-x

Cleary PW (2019) Effect of rock shape representation in DEM on flow and energy utilisation in a pilot SAG mill. Comput Part Mech 6(3):461–477. https://doi.org/10.1007/s40571-019-00226-3

Langston PA, Tüzün U, Heyes DM (1995) Discrete element simulation of granular flow in 2D and 3D hoppers: dependence of discharge rate and wall stress on particle interactions. Chem Eng Sci 50(6):967–987. https://doi.org/10.1016/0009-2509(94)00467-6

González-Montellano C, Ramírez Á, Gallego E, Ayuga F (2011) Validation and experimental calibration of 3D discrete element models for the simulation of the discharge flow in silos. Chem Eng Sci 66(21):5116–5126. https://doi.org/10.1016/j.ces.2011.07.009

Masson S, Martinez J (2000) Effect of particle mechanical properties on silo flow and stresses from distinct element simulations. Powder Technol 109(1):164–178. https://doi.org/10.1016/S0032-5910(99)00234-X

Yang S-C, Hsiau S-S (2001) The simulation and experimental study of granular materials discharged from a silo with the placement of inserts. Powder Technol 120(3):244–255. https://doi.org/10.1016/S0032-5910(01)00277-7

Chou C-S, Lee A-F, Yeh C-K (2009) Placement of a non-isosceles-triangle insert in an asymmetrical two-dimensional bin-hopper. Adv Powder Technol 20(1):80–88. https://doi.org/10.1016/j.apt.2008.03.001

Goda TJ, Ebert F (2005) Three-dimensional discrete element simulations in hoppers and silos. Powder Technol 158(1):58–68. https://doi.org/10.1016/j.powtec.2005.04.019

Anand A, Curtis JS, Wassgren CR, Hancock BC, Ketterhagen WR (2008) Predicting discharge dynamics from a rectangular hopper using the discrete element method (DEM). Chem Eng Sci 63(24):5821–5830. https://doi.org/10.1016/j.ces.2008.08.015

Anand A, Curtis JS, Wassgren CR, Hancock BC, Ketterhagen WR (2009) Predicting discharge dynamics of wet cohesive particles from a rectangular hopper using the discrete element method (DEM). Chem Eng Sci 64(24):5268–5275. https://doi.org/10.1016/j.ces.2009.09.001

Balevičius R, Kačianauskas R, Mróz Z, Sielamowicz I (2011) Analysis and DEM simulation of granular material flow patterns in hopper models of different shapes. Adv Powder Technol 22(2):226–235. https://doi.org/10.1016/j.apt.2010.12.005

Höhner D, Wirtz S, Scherer V (2012) A numerical study on the influence of particle shape on hopper discharge within the polyhedral and multi-sphere discrete element method. Powder Technol 226:16–28. https://doi.org/10.1016/j.powtec.2012.03.041

Höhner D, Wirtz S, Scherer V (2013) Experimental and numerical investigation on the influence of particle shape and shape approximation on hopper discharge using the discrete element method. Powder Technol 235:614–627. https://doi.org/10.1016/j.powtec.2012.11.004

Liu SD, Zhou ZY, Zou RP, Pinson D, Yu AB (2014) Flow characteristics and discharge rate of ellipsoidal particles in a flat bottom hopper. Powder Technol 253(Supplement C):70–79. https://doi.org/10.1016/j.powtec.2013.11.001

Höhner D, Wirtz S, Scherer V (2015) A study on the influence of particle shape on the mechanical interactions of granular media in a hopper using the discrete element method. Powder Technol 278:286–305. https://doi.org/10.1016/j.powtec.2015.02.046

Gui N, Yang X, Tu J, Jiang S (2017) Effect of roundness on the discharge flow of granular particles. Powder Technol 314:140–147. https://doi.org/10.1016/j.powtec.2016.09.056

Khazeni A, Mansourpour Z (2018) Influence of non-spherical shape approximation on DEM simulation accuracy by multi-sphere method. Powder Technol 332:265–278. https://doi.org/10.1016/j.powtec.2018.03.030

Tangri H, Guo Y, Curtis JS (2019) Hopper discharge of elongated particles of varying aspect ratio: experiments and DEM simulations. Chem Eng Sci X 4:100040. https://doi.org/10.1016/j.cesx.2019.100040

Wang P, Zhu L, Zhu X (2016) Flow pattern and normal pressure distribution in flat bottom silo discharged using wall outlet. Powder Technol 295:104–114. https://doi.org/10.1016/j.powtec.2016.03.036

Wan J, Wang F, Yang G, Zhang S, Wang M, Lin P, Yang L (2018) The influence of orifice shape on the flow rate: a DEM and experimental research in 3D hopper granular flows. Powder Technol 335:147–155. https://doi.org/10.1016/j.powtec.2018.03.041

Xue J, Schiano S, Zhong W, Chen L, Wu C-Y (2018) Determination of the flow/no-flow transition from a flat bottom hopper. Powder Technol. https://doi.org/10.1016/j.powtec.2018.08.063

Zhang Y, Jia F, Zeng Y, Han Y, Xiao Y (2018) DEM study in the critical height of flow mechanism transition in a conical silo. Powder Technol 331:98–106. https://doi.org/10.1016/j.powtec.2018.03.024

Ge L, Gui N, Yang X, Tu J, Jiang S (2019) Effects of aspect ratio and component ratio on binary-mixed discharging pebble flow in hoppers. Powder Technol 355:320–332. https://doi.org/10.1016/j.powtec.2019.07.045

Ji S, Wang S, Peng Z (2019) Influence of external pressure on granular flow in a cylindrical silo based on discrete element method. Powder Technol 356:702–714. https://doi.org/10.1016/j.powtec.2019.08.083

Liu H, Jia F, Xiao Y, Han Y, Li G, Li A, Bai S (2019) Numerical analysis of the effect of the contraction rate of the curved hopper on flow characteristics of the silo discharge. Powder Technol 356:858–870. https://doi.org/10.1016/j.powtec.2019.09.033

Zaki M, Siraj MS (2019) Study of a flat-bottomed cylindrical silo with different orifice shapes. Powder Technol 354:641–652. https://doi.org/10.1016/j.powtec.2019.06.041

Zhao Y, Yang S, Zhang L, Chew JW (2019) Understanding the varying discharge rates of lognormal particle size distributions from a hopper using the discrete element method. Powder Technol 342:356–370. https://doi.org/10.1016/j.powtec.2018.09.080

Wang Y, Lu Y, Ooi JY (2013) Numerical modelling of dynamic pressure and flow in hopper discharge using the arbitrary Lagrangian–Eulerian formulation. Eng Struct 56:1308–1320. https://doi.org/10.1016/j.engstruct.2013.07.006

Wang Y, Lu Y, Ooi JY (2015) A numerical study of wall pressure and granular flow in a flat-bottomed silo. Powder Technol 282:43–54. https://doi.org/10.1016/j.powtec.2015.01.078

Zheng QJ, Xia BS, Pan RH, Yu AB (2017) Prediction of mass discharge rate in conical hoppers using elastoplastic model. Powder Technol 307(Supplement C):63–72. https://doi.org/10.1016/j.powtec.2016.11.037

Huang X, Zheng Q, Yu A, Yan W (2019) Shape optimization of conical hoppers to increase mass discharging rate. Powder Technol. https://doi.org/10.1016/j.powtec.2019.09.043

Ketterhagen WR, Curtis JS, Wassgren CR (2005) Stress results from two-dimensional granular shear flow simulations using various collision models. Phys Rev E 71(6):061307. https://doi.org/10.1103/PhysRevE.71.061307

Hertz H (1882) On the contact of elastic solids. J Reine Angew Math 92:156–171

Mindlin RD (1949) Compliance of elastic bodies in contact. J Appl Mech 16(3):259–268

Mindlin RD, Deresiewicz H (1953) Elastic spheres in contact under varying oblique forces. J Appl Mech 20(3):327–344

Tsuji Y, Tanaka T, Ishida T (1992) Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol 71(3):239–250. https://doi.org/10.1016/0032-5910(92)88030-L

Sakaguchi H, Ozaki E, Igarashi T (1993) Plugging of the flow of granular materials during the discharge from a silo. Int J Mod Phys B 7:1949–1963

Zeng Y, Jia F, Zhang Y, Meng X, Han Y, Wang H (2017) DEM study to determine the relationship between particle velocity fluctuations and contact force disappearance. Powder Technol 313:112–121. https://doi.org/10.1016/j.powtec.2017.03.022

Nedderman RM, Laohakul C (1980) The thickness of the shear zone of flowing granular materials. Powder Technol 25(1):91–100. https://doi.org/10.1016/0032-5910(80)87014-8

Acknowledgements

This work has been financially supported by National Key R&D Program of China (2017YFB0603504-2) and Shandong Provincial Natural Science Foundation, China (ZR2017LEE019 and ZR2014EL030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Liu, Y., Zheng, B. et al. Discharge characteristics of binary particles in a rectangular hopper with inclined bottom. Comp. Part. Mech. 8, 315–324 (2021). https://doi.org/10.1007/s40571-020-00332-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-020-00332-7