Summary

Although qualitative pictures of the flow pattern in moving powders and bulk solids have been published, there is no quantitative evidence on the velocity profiles. This was needed in developing an energy theorem determining flow rates (Brown, Nature, 1961, 191, 458–461) and the experiments described here were undertaken to test various suppositions made at that time. It is shown that the assumptions made were correct.

The gravity flow of dry powders and bulk solids through apertures cannot begin until the powder has dilated. The friction caused by the motion then determines the flow pattern.

In this paper only those materials that flow freely under gravity are considered. In such materials cohesive forces between the grains are inappreciable. The results are expected to apply to all bulk solids that do not contain large quantities of finely-divided powders in the range of sizes below 20 to 30 microns, and to closely graded powders with particles larger than about 100 microns. In all cases it is assumed that the moisture content is in equilibrium with the ambient air.

Measurements of the voidage in a single layer of ballbearings flowing down an inclined plate show that dilatant waves pass upward through the bed. Below the aperture the emergent stream forms a vena contracta. At the aperture there is a statistically empty space adjacent to the edges, through which few balls pass. The existence of a free-fall arch at the aperture is demonstrated, below which the grains fall freely under gravity.

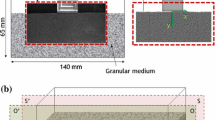

By fixing a flowing system in wax it is shown that the flow just above the free-fall arch is radial, converging to an apex below the aperture, and that the flowing region is bounded by the surfaces of sliding that separate flowing from non-flowing material.

By observing the flow of powder through a transparent end face, the angle to the vertical (β degrees) of the surface of sliding at the aperture has been measured for (a) flow through a central slot (βc o), (b) flow through an edge slot adjacent to a vertical wall (βE o). A different method was used to determine the inclination of the surface of sliding through a central circular aperture (β3 o). It was found that β3 o < βc o ⩽ βE o.

The surfaces of sliding are steeper than the drained angle of repose of a conical heap.

Similar content being viewed by others

Abbreviations

- f :

-

downward acceleration cm sec−2

- l :

-

length of slot aperture cm

- Q :

-

total mass flow rate through an aperture g s−1

- R :

-

length of a radius vector from the apex in radial flow cm

- R 0 :

-

initial length of radius vector in radial flow cm

- dS :

-

elementary area of a stream tube cm2

- t :

-

time from start of flow sec

- T :

-

total energy of flowing system per unit volume g cm−1 sec−2

- v :

-

radial velocity of an assembly of grains cm sec−1

- dV :

-

elementary volume in a stream tube cm3

- x 0 :

-

angle to the horizontal of a slip plane

- α :

-

drained angle of repose of a conical heap

- β :

-

angle of approach of the flowing zone to the vertical

- β E :

-

angle of approach above a slot adjacent to a vertical end face

- β c :

-

angle of approach above a central slot in a flat floor

- β 3 :

-

angle of approach above a central circular orifice in a flat floor

- λ :

-

constant. The slope of (R 2,t) graphs is 2λ

- Φ :

-

angle of internal friction

- Φ 1 :

-

angle of friction between powder and a wall

- ψ :

-

angle of inclination (to the horizontal) of the wall of a trough

- ϱ :

-

minimum bulk density g cm−3

- θ :

-

inclination of a radius vector to the vertical

References

Airy, W., Proc. Inst. Civil Engrs131, 347 (1897).

Brown, R. L., Nature, Lond.191, 458 (1961).

Brown, R. L. andJ. C. Richards, Trans. Instn. Chem. Engrs37, 108 (1959).

Brown, R. L. andJ. C. Richards, Trans. Instn. Chem. Engrs38, 243 (1960).

Delaplaine, J. W., J. Amer. Inst., Chem. Engrs2 (March), 127, (Sept.), 371 (1956).

Jenike, A. W., P. J. Elsey, andR. H. Woolley, Proc. Amer. Soc. Test Materials60, 1168 (1960).

Kvapil, R., Statni Nakladatelstve Teck. Literatury (10), 629 (Prague 1960).

Martin, J. B. andJ. C. Richards, J. Sci. Technol.11 (1), 31 (1965).

Meldau, R. andE. Stach, J. Inst. Fuel7, 336 (1934).

Reynolds, O., Phil. Mag.20, 469 (1885).

Voellmy, A., Eingebettete Rohre (Zürich 1937).

Zenz, F. A. andD. F. Othmer, Fluidization and Fluid Particle Systems (New York 1959).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Brown, R.L., Richards, J.C. Kinematics of the flow of dry powders and bulk solids. Rheol Acta 4, 153–165 (1965). https://doi.org/10.1007/BF01969251

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01969251