Abstract

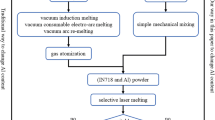

Selective laser melting (SLM) of aluminium alloys for lightweight application is arousing widespread interest, but the available alloy compositions are limited due to unsatisfactory mechanical performances. The rapid solidification of SLM provides a pathway to design a novel alloy composition with extended solubility. This strategy is demonstrated by an additively manufactured novel Al–2.51Mn–2.71Mg–0.55Sc–0.29Cu–0.31Zn alloy with the supersaturated solid solution in the present study. The microstructure of as-build sample is characterized with multi-modal grains with the fine equiaxed grain (FEG, ~ 800 nm) at molten pool boundaries, coarse equiaxed grain (CEG, ~ 2 μm) and columnar dendrites (CD, ~ 4 μm) inside the molten pool, which relates to the precipitations type and distribution. It is observable that Al3(Sc, Zr) precipitation particles with the size of ~ 50 nm are dispersed in the FEG zone, while the interior of CEG shows no Al3(Sc, Zr) particle which only exists at the CEG boundaries. Regardless of FEG, CEG or CD, the slender Al6Mn precipitation with the length of ~ 500 nm is distributed along the grain boundaries. Meanwhile, a lot of vacancies and thickness fringes are detected in the FEG zone, which confirms the supersaturated solid solution in laser rapid solidification. The ultimate tensile strength and yield strength of the as-printed sample are ~ 380 MPa and ~ 330 MPa, respectively, with elongation ~ 14%, which increase to ~ 440 MPa and ~ 410 MPa with a reduction of elongation to ~ 9% after heat treatment.

Similar content being viewed by others

References

J. Zhang, B. Song, Q. Wei, D. Bourell, Y. Shi, J. Mater. Sci. Technol. 35, 270 (2019)

E.O. Olakanmi, R.F. Cochrane, K.W. Dalgarno, Prog. Mater. Sci. 74, 401 (2015)

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, M. Qian, Acta Mater. 85, 74 (2015)

R.R. Dehoff, S.S. Babu, Acta Mater. 58, 4305 (2010)

M. Vlach, I. Stulikova, B. Smola, T. Kekule, H. Kudrnova, S. Danis, R. Gemma, V. Ocenasek, J. Malek, D. Tanprayoon, V. Neubert, Mater. Charact. 86, 59 (2013)

B. Forbord, H. Hallem, N. Ryum, K. Marthinsen, Mater. Sci. Eng. A 387–389, 936 (2004)

F. Jiang, H. Zhang, X. Ji, X. Meng, L. Li, Mater. Sci. Eng. A 595, 10 (2014)

K. Liu, A.M. Nabawy, X.G. Chen, Trans. Nonferrous Met. Soc. China 27, 771 (2017)

K. Liu, X.G. Chen, Mater. Sci. Eng. A 697, 141 (2017)

K. Liu, H. Ma, X.G. Chen, J. Alloys Compd. 694, 354 (2017)

K.L. Kendig, D.B. Miracle, Acta Mater. 50, 4165 (2002)

O.N. Senkov, M.R. Shagiev, S.V. Senkova, D.B. Miracle, Acta Mater. 56, 3723 (2008)

M.E. Krug, Z. Mao, D.N. Seidman, D.C. Dunand, Acta Mater. 79, 382 (2014)

M. Vlach, I. Stulíková, B. Smola, N. Žaludová, Mater. Charact. 61, 1400 (2010)

M. Vlach, I. Stulikova, B. Smola, J. Piesova, H. Cisarova, S. Danis, J. Plasek, R. Gemma, D. Tanprayoon, V. Neubert, Mater. Sci. Eng. A 548, 27 (2012)

A.B. Spierings, K. Dawson, K. Kern, F. Palm, K. Wegener, Mater. Sci. Eng. A 701, 264 (2017)

T. Yu, J. Liu, Y. He, J. Tian, M. Chen, Y. Wang, Wear 476, 203581 (2021).

A.B. Spierings, K. Dawson, P.J. Uggowitzer, K. Wegener, Mater. Des. 140, 134 (2018)

R. Li, M. Wang, T. Yuan, B. Song, C. Chen, K. Zhou, P. Cao, Powder Technol. 319, 117 (2017)

M. Wang, R. Li, T. Yuan, C. Chen, L. Zhou, H. Chen, M. Zhang, S. Xie, Mater. Sci. Eng. A 756, 354 (2019)

Q. Jia, P. Rometsch, P. Kürnsteiner, Q. Chao, A. Huang, M. Weyland, L. Bourgeois, X. Wu, Acta Mater. 171, 108 (2019)

H. Asgari, C. Baxter, K. Hosseinkhani, M. Mohammadi, Mater. Sci. Eng. A 707, 148 (2017)

W. Li, S. Li, J. Liu, A. Zhang, Y. Zhou, Q. Wei, C. Yan, Y. Shi, Mater. Sci. Eng. A 663, 116 (2016)

A.B. Spierings, K. Dawson, T. Heeling, P.J. Uggowitzer, R. Schäublin, F. Palm, K. Wegener, Mater. Des. 115, 52 (2017)

R. Li, M. Wang, Z. Li, P. Cao, T. Yuan, H. Zhu, Acta Mater. 193, 83 (2020)

Y.K. Kim, J. Choe, K.A. Lee, J. Alloys Compd. 805, 680 (2019)

Z. Zribi, H.H. Ktari, F. Herbst, V. Optasanu, N. Njah, Mater. Charact. 153, 190 (2019)

Y. Shi, K. Yang, S.K. Kairy, F. Palm, X. Wu, P.A. Rometsch, Mater. Sci. Eng. A 732, 41 (2018)

W. Li, Y. Yang, J. Liu, Y. Zhou, M. Li, S. Wen, Q. Wei, C. Yan, Y. Shi, Acta Mater. 136, 90 (2017)

J. Bi, Z. Lei, Y. Chen, X. Chen, Z. Tian, J. Liang, X. Zhang, X. Qin, Mater. Sci. Eng. A 768, 138478 (2019)

X. Yang, D. Wang, Z. Wu, J. Yi, S. Ni, Y. Du, M. Song, Mater. Sci. Eng. A 658, 16 (2016)

J.H. Zheng, Y. Dong, K. Zheng, H. Dong, J. Lin, J. Jiang, T.A. Dean, J. Alloys Compd. 810, 151934 (2019)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (51871249), the Guangxi Key Research and Development Programme (Guike AB19050002), the Science and Technology Planning Project of Shenzhen (JCYJ20180508151903646), the Hunan Science Fund for Distinguished Young Scholars (2020JJ2046), Natural Science Foundation of Shandong Province (ZR2020ZD04) and the Huxiang Youth Talent Support Programme (2018RS3007).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Wang, M., Li, R., Yuan, T. et al. Microstructure and Mechanical Properties of Selective Laser Melted Al–2.51Mn–2.71Mg–0.55Sc–0.29Cu–0.31Zn Alloy Designed by Supersaturated Solid Solution. Acta Metall. Sin. (Engl. Lett.) 35, 354–368 (2022). https://doi.org/10.1007/s40195-021-01290-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01290-6