Abstract

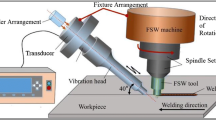

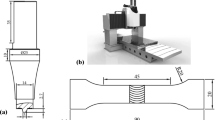

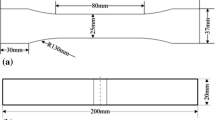

Friction stir welding (FSW) and ultrasonic vibration-assisted FSW (UVaFSW) experiments of AA2024 aluminum alloy and AZ31B magnesium alloy plates with thickness of 3 mm were carried out. The effects of ultrasonic vibration on the microstructures and mechanical properties of dissimilar joints were investigated. The test results show that with application of ultrasonic vibration, the mechanical interlocking degree of AA2024/AZ31B dissimilar materials in the weld nugget zone (WNZ) was enhanced, and the thickness of intermetallic compounds at top and lower parts of WNZ was reduced. Therefore, the joint tensile strength was improved in UVaFSW. The exerted ultrasonic vibration caused only about 5–10 °C variation of the peak temperature in welding, indicating that the acoustic softening effect plays more important roles than the thermal effect of ultrasonic vibration. It lays foundation for the process optimization and joint quality control in welding of dissimilar AA2024 and AZ31B alloys which are of great application prospects in aircraft and space craft industries.

Similar content being viewed by others

References

Shah LH, Othman NH, Gerlich A (2018) Review of research progress on aluminum-magnesium dissimilar friction stir welding. Sci Technol Weld Join 23:256–270

Liu L, Ren D, Liu F (2014) A review of dissimilar welding techniques for magnesium alloy to aluminium alloys. Materials 7:3735–3757

Firouzdor V, Kou S (2010) Al-to-Mg friction stir welding: effect of material position, travel speed, and rotation speed. Metall Mater Trans A 41:2914–2935

Firouzdor V, Kou S (2010) Formation of liquid and intermetallics in Al-to-Mg friction stir welding. Metall Mater Trans A 41:3238–3251

Fu B, Qin G, Li F, Meng X, Zhang J, Wu CS (2015) Friction stir welding process of dissimilar metals of 6061–T6 aluminum alloy to AZ31B magnesium alloy. J Mater Process Technol 218:38–47

Padhy GK, Wu CS, Gao S (2015) Auxiliary energy assisted friction stir welding - a status review. Sci Technol Weld Join 20:631–649

Lv XQ, Wu CS, Padhy GK (2018) Weld microstructure and mechanical properties in ultrasonic enhanced friction stir welding of Al alloy to Mg alloy. J Mater Process Technol 254:145–157

Yao ZH, Kim GY, Wang ZH, Faidley L, Zou QZ, Mei DQ, Chen ZC (2012) Acoustic softening and residual hardening in aluminum: Modeling and experiments. Int J Plasticity 39:75–87

Tian SS, Wang L, Wu CS, Tanaka M (2021) Influence of ultrasonic vibration on keyholing/penetrating capability in plasma arc welding with controlled pulse waveform. Welding in the World 64:1412–1419

Qiao JN, Fang BX, Wu CS (2022) Effect of pulsed power ultrasonic vibration on keyholing/penetrating capability in waveform-controlled plasma arc welding. Welding in the World 65:529–539

Liu XC, Wu CS, Padh GK (2015) Characterization of plastic deformation and material flow in ultrasonic vibration enhanced friction stir welding. Scr Mater 102:95–98

Wu CS, Wang T, Su H (2022) Material flow velocity, strain and strain rate in ultrasonic vibration enhanced friction stir welding of dissimilar Al/Mg alloys. J Manufac Proc 75:13–22

Meng X, Jin Y, Ji SD (2018) Yan D (2018) Improving friction stir weldability of Al/Mg alloys via ultrasonically diminishing pin adhesion. J Mater Sci Technol 34:107–112

Strass B, Wagner G, Conrad C, Wolter B, Benfer S, Fuebeth W (2014) Realization of Al/Mg-hybrid-joints by ultrasound supported friction stir welding - mechanical properties, microstructure and corrosion behavior. Mater Sci Forum 783–786:1814–1819

Zhao J, Wu CS, Su H (2021) Ultrasonic effect on thickness variations of intermetallic compound layers in friction stir welding of aluminium/magnesium alloys. J Manufac Proc 62:388–402

Kumar S, Wu CS, Shi L (2020) Intermetallic diminution during friction stir welding of dissimilar Al/Mg alloys in lap configuration via ultrasonic assistance Metall. Mater Trans A 51:5725–5742

Benfer S, Strass B, Wagner G, Fuebeth W (2016) Manufacturing and corrosion properties of ultrasound supported friction stir welded Al/Mg-hybrid joints Surf. Inter Anal 48:843–852

Zhao WZ, Wu CS (2019) Constitutive equation including acoustic stress work and plastic strain for modeling ultrasonic vibration assisted friction stir welding process. Int J Mach Tool Manufac 145:103434

Shi L, Wu CS, Gao S, Padhy GK (2016) Modified constitutive equation for use in modelling the ultrasonic vibration enhanced friction stir welding process. Scripta Mater 119:21–26

Lv XQ, Wu CS, Sun Z (2022) Effects of ultrasonic vibration on material flow and thermal cycles in friction stir welding of dissimilar Al/Mg alloys. Metall Mater Trans A 54:1572–1584

Zhao J, Wu CS, Su H (2022) Ultrasonic vibration induced thinning of intermetallic compound layers in friction stir welding of dissimilar Al/Mg alloys. Sci Technol Weld Joining 27:621–628

Funding

This study is funded by the National Natural Science Foundation of China (Grant No. 52035005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tan, M., Wu, C. & Su, H. Ultrasonic effects on microstructures and mechanical properties of friction stir weld joints of dissimilar AA2024/AZ31B alloys. Weld World 67, 373–384 (2023). https://doi.org/10.1007/s40194-022-01429-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01429-8