Abstract

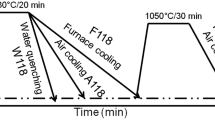

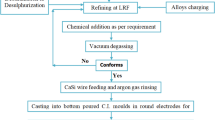

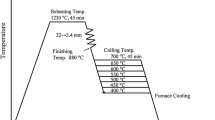

The present work critically investigates the effect of various heat treatments and continuous cooling rates on mechanical properties and microstructural attributes of 0.18%-C steel. During heat treatment, the heating temperature and holding time were kept at 925 °C and 1 h, respectively, for five different samples. Another sample was kept in ‘as received’ condition so that a comparative analysis could be done on its behalf. Mechanical properties like tensile strength, hardness, toughness, and shear strength were determined and analyzed for each sample. The microstructural changes were observed through an optical microscope. Coarse and fine pearlites with proeutectoid ferrite regions were mainly observed in microstructural images. The fracture behavior of the materials was observed by field emission scanning electron microscope. Both ductile and brittle fractures were observed in the broken specimens. Heat-treated samples showed a remarkable reduction in tensile strength and shear strength with a significant improvement in extension values prior to failure. The sand-cooled and furnace-cooled samples exhibited 58% and 46% enhancement in ductility. Similarly, the toughness of all the heat-treated products got increased except for air-cooled sample. Because of fine pearlite, the hardness of air-cooled, sand + brine cooled, and sand + oil-cooled specimens has increased by 4%, 20%, and 9%, respectively, in comparison with the original specimen. Also, the lamellar ferrite + cementite regions have made the sand-cooled and furnace-cooled specimens tougher than the original specimen.

Similar content being viewed by others

References

W.D. Callister Jr., D.G. Rethwisch, Materials science and engineering: an introduction, 10th edn. (Wiley, New York, 2018)

S.H. Avner, Introduction to physical metallurgy, 2nd edn. (McGraw Hill Education, Noida, 2017)

G.E. Dieter, Mechanical metallurgy, 3rd edn. (McGraw Hill Education, Noida, 2017)

P. Jovicevic-Klug, G. Pus, M. Jovicevi-Klug, B. Zuzek, B. Podgornik, Influence of heat treatment parameters on effectiveness of deep cryogenic treatment on properties of high-speed steels. Mater. Sci. Eng., A 829, 142157 (2022). https://doi.org/10.1016/j.msea.2021.142157

A.H. Seikh, Influence of heat treatment on the corrosion of micro alloyed steel in sodium chloride solution. J. Chem. (2013). https://doi.org/10.1155/2013/587514

L. Hao, Z. Liyuan, Z. Boyang, Z. Qingdong, Effect of heat treatment on the microstructure and corrosion resistance of stainless/carbon steel bimetal plate. Adv. Mater. Sci. Eng. (2020). https://doi.org/10.1155/2020/1280761

L. Jingfa, G. Yongsheng, L. Tao, W. Zhan, Effects of heat treatment on the microstructure and mechanical properties of selective laser melting 316L stainless steel. Shock Vibr. (2021). https://doi.org/10.1155/2021/6547213

Ş Baday, H. Başak, F. Sönmez, Investigation and optimization of surface roughness with experimental design methods by turning of AISI-1050 after spheroidization heat treatment. SN Appl. Sci. 2, 2104 (2020). https://doi.org/10.1007/s42452-020-03953-y

A.V. Hruzevych, D.O. Derecha, Diffusion-hardening effect on the technological properties of high-temperature steel. SN Appl. Sci. 2, 1139 (2020). https://doi.org/10.1007/s42452-020-2943-5

A. Królicka, K. Radwański, A. Janik, P. Kustroń, A. Ambroziak, Metallurgical characterization of welded joint of nanostructured bainite: regeneration technique versus post welding heat treatment. Materials. 13(21), 4841 (2020). https://doi.org/10.3390/ma13214841

M.N. Brykov, I. Petryshynets, M. Džupon, Y.A. Kalinin, V.G. Efremenko, N.A. Makarenko, D.Y. Pimenov, F. Kováč, Microstructure and properties of heat affected zone in high-carbon steel after welding with fast cooling in water. Materials 13, 5059 (2020). https://doi.org/10.3390/ma13225059

A. Wojtacha, M. Kciuk, M. Opiela, Effect of heat treatment conditions on corrosion resistance of 0.28C–1.4Mn–0.3Si–0.26Cr steel with Nb, Ti, and V microadditions. Materials. 14, 3254 (2021). https://doi.org/10.3390/ma14123254

M. Ahonen, R. Mouginot, T. Sarikka, S. Lindqvist, Z. Que, U. Ehrnstén, I. Virkkunen, H. Hänninen, Effect of thermal ageing at 400 °C on the microstructure of ferrite-austenite interface of nickel-base alloy narrow-gap dissimilar metal weld. Metals 10, 421 (2020). https://doi.org/10.3390/met10030421

J. Syarif, M. Yousuf, Z. Sajuri, A.H. Baghdadi, M. Merabtene, M.Z. Omar, Effect of partial solution treatment temperature on microstructure and tensile properties of 440C martensitic stainless steel. Metals 10, 694 (2020). https://doi.org/10.3390/met10050694

H. Xiao, S. Zheng, Y. Xin, J. Xu, K. Han, H. Li, Q. Zhai, Characterization of microstructure in high hardness surface layer of low-carbon steel. Metals 10, 995 (2020). https://doi.org/10.3390/met10080995

K. Sugimoto, Recent progress of low and medium-carbon advanced martensitic steels. Metals 11, 652 (2021). https://doi.org/10.3390/met11040652

S. Dikić, D. Glišić, A. Fadel, G. Jovanović, N. Radović, Structure and strength of isothermally heat-treated medium carbon Ti–V microalloyed steel. Metals 11(7), 1011 (2021). https://doi.org/10.3390/met11071011

B. Shin, K. Kim, S. Yi, S. Choi, S. Hyun, Microstructure and mechanical properties of cast and hot-rolled medium-carbon steels under isothermal heat-treatment conditions. Metals 11, 1950 (2021). https://doi.org/10.3390/met11121950

P.V. Reddy, B.V. Reddy, P.J. Ramulu, Effect of heat treatment temperatures on formability of SS 304 during tube hydroforming process. SN Appl. Sci. 2, 205 (2020). https://doi.org/10.1007/s42452-020-2026-7

H.K.D.H. Bhadeshia, A.R. Chintha, Critical assessment 41: the strength of undeformed pearlite. Mater. Sci. Technol. 38(16), 1291–1299 (2022). https://doi.org/10.1080/02670836.2022.2079295

R.D.K. Misra, A perspective in the understanding of strength–toughness combination during processing of engineering ferrous alloys. Mater. Technol. (2023). https://doi.org/10.1080/10667857.2023.2278000

G. Mandal, S.K. Ghosh, S. Chatterjee, Effects of TMCP and QT on microstructure and properties of ultrahigh strength steel. Mater. Today: Proc. 18, 5196–5201 (2019)

G. Mandal, N.K. Tewary, S.K. Ghosh, Enhancement of mechanical properties in bainitic steel processed from different austenitization temperatures. Steel Res. Int. 89(2), 1700259 (2018)

G. Mandal, S.K. Ghosh, S. Bera, S. Mukherjee, Effect of partial and full austenitisation on microstructure and mechanical properties of quenching and partitioning steel. Mater. Sci. Eng., A 676, 56–64 (2016)

G. Mandal, S.K. Ghosh, Microstructural evolution and mechanical behaviour of high strength steel treated by quenching and partitioning process. Mater. Today: Proc. 4(9), 9418–9422 (2017)

G. Mandal, I. Dey, S. Mukherjee, S.K. Ghosh, Phase transformation and mechanical properties of ultrahigh strength steels under continuous cooling conditions. J. Market. Res. 19, 628–642 (2022)

S. Dewangan, N. Mainwal, M. Khandelwal, P.S. Jadhav, Performance analysis of heat treated AISI 1020 steel samples on the basis of various destructive mechanical testing and microstructural behaviour. Aust. J. Mech. Eng. 20(1), 74–87 (2022). https://doi.org/10.1080/14484846.2019.1664212

S. Dewangan, S. Behera, M.K. Chowrasia, Comparative analysis into mechanical properties and microstructural attributes of quenched and tempered 02%-C steel. World J. Eng. (2020). https://doi.org/10.1108/WJE-11-2019-0327

S. Dewangan, Analysis of property variation in AISI 1020 steel after heat treatment. AIP Conf. Proc. 2341, 0050008 (2021). https://doi.org/10.1063/5.0050008

S. Dewangan, V.V. Nemade, K.H. Nemade, P.M. Bohra, S.R. Kartha, M.K. Chowrasia, A discussion on mechanical behaviour of heat-treated low carbon steel. Mater. Today: Proc. (2022). https://doi.org/10.1016/j.matpr.2022.03.203

R. Maksuti, Fractographic analysis of welded joint surfaces. Int. Sci. J. Mach. Technol. Mater. 12, 34–37 (2016)

S.K.L. Moorthy, S. Rajaram, P.C.S. Kumar, Optimization of tempering process parameters of AISI 3140 low alloy steel to conserve furnace energy using Tukey’s honestly significant difference test. IOP Conf. Ser. Earth Environ. Sci. 573(1), 012027 (2020). https://doi.org/10.1088/1755-1315/573/1/012027/meta

Funding

The authors declare that no funds, grants, or other support was received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study, conception, and design. All the experimental works were performed by ARK, PVR, and PPS. Manuscript preparation was carried out by SD. Result assessment has been done by SKS. All authors have read and approved the manuscript before submission.

Corresponding author

Ethics declarations

Conflict of interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kulkarni, A.R., Raju, P.V., Sarma, P.P. et al. Microstructure and Mechanical Properties of 0.18%-C Steel Samples Processed Through Five Different Heat Treatment Techniques. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-023-00633-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-023-00633-0