Abstract

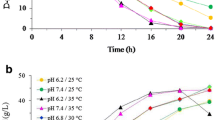

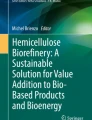

Xylose conversion to xylitol instead of bioethanol is more profitable as it is a high-value chemical with several applications in food and pharma industries. The current study explores the ability of C. tropicalis for bioethanol and xylitol synthesis under anaerobic and aerobic conditions, respectively. Firstly, the effect of agitation (100, 200, 300 and 400 rpm) on glucose fermentation was evaluated. The maximum bioethanol yield and productivity of 0.49 ± 0.008 g/g and 3.62 ± 0.007 g/L/h were achieved at 200 rpm in 8 h. Subsequently, sequential fermentation was performed for bioethanol and xylitol synthesis from the glucose-xylose mixture. Bioethanol in the medium decreased xylose assimilation due to its inhibitory effect on C. tropicalis, resulting in poor xylitol yield. Bioethanol separation via distillation and xylose fed-batch fermentation with glycerol supplementation (2 g/L) was adopted to improve xylitol production. The maximum productivity of bioethanol and xylitol from glucose-xylose (59.04 ± 0.283 g/L, 50.27 ± 0.095 g/L) mixture was 3.52 ± 0.019 g/L/h and 2.19 ± 0.003 g/L/h respectively. These results were analogous to those obtained in the separate glucose and glycerol-supplemented xylose fed-batch fermentation experiments. The suggested strategy in the present work shows potential for developing biorefineries based on lignocellulose materials for the co-production of biofuels and biochemicals.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Chandel AK, Garlapati VK, Jeevan Kumar SP et al (2020) The role of renewable chemicals and biofuels in building a bioeconomy. Biofuels Bioprod Biorefin 14:830–844

Bonan CIDG, Tramontina R, dos Santos MW et al (2021) Biorefinery platform for Spathaspora passalidarum NRRL Y-27907 in the production of ethanol, xylitol, and single cell protein from sugarcane bagasse. Bioenergy Res 15:1169–1181. https://doi.org/10.1007/s12155-021-10255-7

FitzPatrick M, Champagne P, Cunningham MF, Whitney RA (2010) A biorefinery processing perspective: treatment of lignocellulosic materials for the production of value-added products. Bioresour Technol 101:8915–8922

Jain V, Awasthi A, Santhagunam A, Ghosh S (2023) Sequential fermentation with in situ distillation for bioethanol and xylitol production from mixed sugars: a novel approach for lignocellulosic material-based biorefineries. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-04433-0

Philippini RR, Martiniano SE, Ingle AP et al (2020) Agroindustrial byproducts for the generation of biobased products: alternatives for sustainable biorefineries. Front Energy Res 8:152

Sindhu R, Binod P, Pandey A et al (2019) Chapter 5 - Biofuel Production From Biomass: Toward Sustainable Development. In: Kumar S, Kumar R, Pandey A (eds) Current developments in biotechnology and bioengineering. Elsevier, pp 79–92

Barak S, Rahman RK, Neupane S et al (2020) Measuring the effectiveness of high-performance Co-Optima biofuels on suppressing soot formation at high temperature. Proc Natl Acad Sci 117:3451–3460. https://doi.org/10.1073/pnas.1920223117

Kamelian FS, Naeimpoor F, Mohammadi T (2022) Effect of Zymomonas mobilis and Pichia stipitis presence/absence strategies in a two-stage process on bioethanol production from glucose-xylose mixture. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02567-1

Kumar S, Agarwal GP, Sreekrishnan TR (2023) Optimization of co-culture condition with respect to aeration and glucose to xylose ratio for bioethanol production. Indian Chem Eng 65:233–248. https://doi.org/10.1080/00194506.2023.2190332

Kumar RS, Singh P, Ghosh S (2022) Sequential fermentation for enhanced volumetric productivity of bioethanol from mixed sugars. Fuel 308:121984. https://doi.org/10.1016/j.fuel.2021.121984

Gehlot K, Sivakumar R, Ghosh S (2022) In situ distillation strategy to improve the sequential fermentation process using Zymomonas mobilis and Pichia stipitis for bioethanol production from kans grass biomass hydrolysate. Bioenergy Res 15:1958–1971. https://doi.org/10.1007/s12155-021-10383-0

Hor S, Kongkeitkajorn MB, Reungsang A (2022) Sugarcane bagasse-based ethanol production and utilization of its vinasse for xylitol production as an approach in integrated biorefinery. Fermentation 8:340. https://doi.org/10.3390/fermentation8070340

Jain V, Awasthi A, Ghosh S (2023) Biosynthesis of xylitol by cell immobilization: an insight. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03724-2

Jain V, Ghosh S (2023) Biotransformation of lignocellulosic biomass to xylitol: an overview. Biomass Convers Biorefin 13:9643–9661. https://doi.org/10.1007/s13399-021-01904-0

Mordor intelligence (2024) Xylitol market size & share analysis - growth trends & forecasts (2024 - 2029). https://www.mordorintelligence.com/industry-reports/xylitol-market

Laopaiboon L, Thanonkeo P, Jaisil P, Laopaiboon P (2007) Ethanol production from sweet sorghum juice in batch and fed-batch fermentations by Saccharomyces cerevisiae. World J Microbiol Biotechnol 23:1497–1501. https://doi.org/10.1007/s11274-007-9383-x

Cheng K-K, Wu J, Lin Z-N, Zhang J-A (2014) Aerobic and sequential anaerobic fermentation to produce xylitol and ethanol using non-detoxified acid pretreated corncob. Biotechnol Biofuels 7:166. https://doi.org/10.1186/s13068-014-0166-y

Prado CA, Cunha MLS, Terán-Hilares R et al (2023) Hydrodynamic cavitation–assisted oxidative pretreatment and sequential production of ethanol and xylitol as innovative approaches for sugarcane bagasse biorefineries. Bioenergy Res. https://doi.org/10.1007/s12155-022-10555-6

Unrean P, Ketsub N (2018) Integrated lignocellulosic bioprocess for co-production of ethanol and xylitol from sugarcane bagasse. Ind Crops Prod 123:238–246. https://doi.org/10.1016/j.indcrop.2018.06.071

García Martín JF, Cuevas M, Bravo V, Sánchez S (2010) Ethanol production from olive prunings by autohydrolysis and fermentation with Candida tropicalis. Renew Energy 35:1602–1608. https://doi.org/10.1016/j.renene.2009.12.015

Sánchez S, Bravo V, García JF et al (2008) Fermentation of d-glucose and d-xylose mixtures by Candida tropicalis NBRC 0618 for xylitol production. World J Microbiol Biotechnol 24:709–716. https://doi.org/10.1007/s11274-007-9527-z

Kim J-H, Ryu Y-W, Seo J-H (1999) Analysis and optimization of a two-substrate fermentation for xylitol production using Candida tropicalis. J Ind Microbiol Biotechnol 22:181–186. https://doi.org/10.1038/sj.jim.2900626

Jain V, Ghosh S (2023) Xylitol biosynthesis enhancement by Candida tropicalis via medium, process parameter optimization, and co-substrate supplementation. Prep Biochem Biotechnol 1–11. https://doi.org/10.1080/10826068.2023.2209897

Patle S, Lal B (2007) Ethanol production from hydrolysed agricultural wastes using mixed culture of Zymomonas mobilis and Candida tropicalis. Biotechnol Lett 29:1839–1843. https://doi.org/10.1007/s10529-007-9493-4

Patle S, Lal B (2008) Investigation of the potential of agro-industrial material as low cost substrate for ethanol production by using Candida tropicalis and Zymomonas mobilis. Biomass Bioenergy 32:596–602. https://doi.org/10.1016/j.biombioe.2007.12.008

Jeffries TW (1981) Conversion of xylose to ethanol under aerobic conditions by Candida tropicalis. Biotechnol Lett 3:213–218. https://doi.org/10.1007/BF00154647

Madian HR, Hamouda HI, Hosny M (2022) Statistical optimization of bioethanol production from giant reed hydrolysate by Candida tropicalis using Taguchi design. J Biotechnol 360:71–78. https://doi.org/10.1016/j.jbiotec.2022.10.007

Oberoi HS, Vadlani PV, Brijwani K et al (2010) Enhanced ethanol production via fermentation of rice straw with hydrolysate-adapted Candida tropicalis ATCC 13803. Process Biochem 45:1299–1306. https://doi.org/10.1016/j.procbio.2010.04.017

Mattam AJ, Kuila A, Suralikerimath N et al (2016) Cellulolytic enzyme expression and simultaneous conversion of lignocellulosic sugars into ethanol and xylitol by a new Candida tropicalis strain. Biotechnol Biofuels 9:157. https://doi.org/10.1186/s13068-016-0575-1

Arruda PV, Felipe MGA (2009) Role of glycerol addition on xylose-to-xylitol bioconversion by Candida guilliermondii. Curr Microbiol 58:274–278. https://doi.org/10.1007/s00284-008-9321-7

Kim J-H, Han K-C, Koh Y-H et al (2002) Optimization of fed-batch fermentation for xylitol production by Candida tropicalis. J Ind Microbiol Biotechnol 29:16–19. https://doi.org/10.1038/sj.jim.7000257

Li M, Meng X, Diao E, Du F (2012) Xylitol production by Candida tropicalis from corn cob hemicellulose hydrolysate in a two-stage fed-batch fermentation process. J Chem Technol Biotechnol 87:387–392. https://doi.org/10.1002/jctb.2732

Swain MR, Krishnan C (2015) Improved conversion of rice straw to ethanol and xylitol by combination of moderate temperature ammonia pretreatment and sequential fermentation using Candida tropicalis. Ind Crops Prod 77:1039–1046. https://doi.org/10.1016/j.indcrop.2015.10.013

Castañón-Rodríguez JF, Domínguez-González JM, Ortíz-Muñiz B et al (2015) Continuous multistep versus fed-batch production of ethanol and xylitol in a simulated medium of sugarcane bagasse hydrolyzates. Eng Life Sci 15:96–107. https://doi.org/10.1002/elsc.201400098

Acknowledgements

The authors gratefully acknowledge the constant support provided by the Indian Institute of Technology Roorkee (IITR), the Department of Biotechnology (DBT), and the Ministry of Human Resource and Development (MHRD).

Funding

The authors are grateful to the Indian Institute of Technology Roorkee (IIT R), India, the Ministry of Human Resource and Development (MHRD), India, and the Department of Biotechnology (DBT), India, for providing financial support in the form of fellowship and Research Grant (Grant number: DBT-1724-BIO, 17559007).

Author information

Authors and Affiliations

Contributions

Vasundhara Jain: conceptualisation, methodology, data curation, formal analysis, experimentation, validation, writing—review and editing.

Sanjoy Ghosh: guidance, project administration, review and proofreading.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jain, V., Ghosh, S. Biotransformation of mixed sugars to bioethanol and xylitol by Candida tropicalis using sequential fermentation: an innovative strategy towards biorefinery development. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05272-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05272-3