Abstract

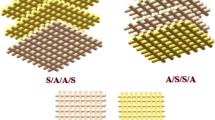

This study investigated the behavior of layered aloe vera and silk woven fiber in an epoxy composite filled with copper slag powder at sub (3–4 GHz)- and hyper (8–20 GHz)-frequency bands. The main goal of this work was to explore how the stacking order of fabrics affected the EMI shielding and to create an efficient EMI shielding material for protecting electronic devices from EMI attack. The ASTM standards were used to characterize the composite laminates, which were created utilizing the hand layup method. According to the findings, the fiber with the staking sequence silk/aloe vera/silk/aloe vera demonstrates increased dielectric values of 5%, 14%, 25%, and 66% at sub- and hyper-frequency bands. The composite designation RA2 has a higher dielectric constant than the other composite designations, which are respectively 5.6, 3.1, 1.80, and 0.70. The use of silk fiber further improves the EMI shielding qualities. At sub- and hyper-frequency bands, the composite designation RA2 records up to 6.4, 15.4, 34.1, and 48.3dB. It should be emphasized that the composites also have better mechanical properties. The material RA2 exhibited the highest mechanical qualities, including tensile strength, flexural strength, Izod impact, and hardness of up to 164 MPa, 216 MPa, 6.22 J, and 91 shore-D. These composite materials, which have good mechanical, dielectric, and shielding capabilities, could be used in the satellite, aerospace, defense, industrial, instrumentation and electronic industries.

Similar content being viewed by others

Data availability

All data available in manuscript itself.

References

Alshahrani H, Prakash VRA (2023) Development of highly flexible electromagnetic interference shielding composites for electronic applications using Cobalt/Hevea brasiliensis seed husk carbon dots/Bamboo microfibre-polyvinyl alcohol. Ind Crops Prod 191:115967

Prakash VRA, Rajadurai A, Jayaseelan V, Jerome Das S, Murali M, Jaisingh SJ (2019) Role of silanized magnetic Fe2O3 particle in heat dissipation and microwave shielding behavior of E-glass fibre-reinforced epoxy resin composite. Mater Res Express 6(7):076113

Prakash VRA, Viswanthan R (2019) Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos Part A Appl Sci Manuf 118:317–326

Liang C et al (2021) Structural design strategies of polymer matrix composites for electromagnetic interference shielding: a review. Nano-Micro Lett 13:181. https://doi.org/10.1007/s40820-021-00707-2

Merizgui T, Prakash VR, Gaoui B, Sebaey TA (2022) Microwave shielding performance of TiO2/Co/GF containing high structure carbon fiber alternate laminate composite. J Mater Sci Mater Electron 33(2):934–949

Balaji N et al (2022) Biomass Convers Biorefin:1–9. https://doi.org/10.1007/s13399-022-02650-7

Suganya G et al (2022) Biomass Convers Biorefin:1–8. https://doi.org/10.1007/s13399-022-02787-5

Kalusuraman G (2019) et al. Measurement 148:106950. https://doi.org/10.1016/j.measurement.2019.106950

Zhang J et al (2022) Powder Technol 410:117891. https://doi.org/10.1016/j.powtec.2022.117891

Gabasiane TS et al (2021) Crystals 11:1504. https://doi.org/10.3390/cryst11121504

Prakash VA, Rajadurai A (2016) Thermo-mechanical characterization of silane treated E-glass fiber/hematite particles reinforced epoxy resin hybrid composite. Appl Surf Sci 384:99–106. https://doi.org/10.1016/j.apsusc.2016.04.185

Arun Prakash VR, Rajadurai A (2016) Appl Phys A 122(10):875. https://doi.org/10.1007/s00339-016-0411-2

Arun Prakash VR, Viswanathan R (2018) Polym Bull 75:4207–4225. https://doi.org/10.1007/s00289-017-2262-1

Yu Z et al (2022) Mater Today Commun 32:104046. https://doi.org/10.1016/j.mtcomm.2022.104046

Vincent A et al (2021) Trans Electr Electron Mater 22:794–802. https://doi.org/10.1007/s42341-021-00299-z

Merizgui T et al (2020) Trans Electr Electron Mater. https://doi.org/10.1007/s42341-020-00179-y

Fernández-González D et al (2021) Metals 11:1032. https://doi.org/10.3390/met11071032

Long W-J et al (2021) Materials 14:4374. https://doi.org/10.3390/ma14164374

Wang Y et al (2020) Mater Des 191:108698. https://doi.org/10.1016/j.matdes.2020.108698

John Prabhahar M et al (2020) Mater Res Express 7:016106. https://doi.org/10.1088/2053-1591/ab6389

Ozturk M et al (2021) J Build Eng 41:102757. https://doi.org/10.1016/j.jobe.2021.102757

Zhao Y et al (2022) Small Sci 2(2):2100077. https://doi.org/10.1002/smsc.202100077

Merizgui T et al (2018) Mater Res Express 23:22. https://doi.org/10.1088/20531591/11f9de

Anu KS et al (2022) J Indian Chem Soc:100720. https://doi.org/10.1016/j.jics.2022.100720

Fan W et al (2018) Text Res J 88(20):2353–2361. https://doi.org/10.1177/0040517517723022

Wu C et al (2019) Mechanical properties and impact performance of silk-epoxy resin composites modulated by flax fibres. Compos Part A Appl Sci Manuf 117:357–368

Darshan SM et al (2021) Mater Today: Proc 43:986–994. https://doi.org/10.1016/j.matpr.2020.07.618

Zuraidah Z et al (2020) Polym-Plast Technol Mater 59(18):1987–2002. https://doi.org/10.1080/25740881.2020.1784215

Alshahrani H, Prakash VRA (2022) Mechanical, fatigue and DMA behaviour of high content cellulosic corn husk fibre and orange peel biochar epoxy biocomposite: a greener material for cleaner production. J Clean Prod 374:133931

Alshahrani H, Pathinettampadian G, Gujba AK, Rethnam APV (2022) J Ind Text 52:15280837221137382

Author information

Authors and Affiliations

Contributions

Ramesh B: Research, drafting, and proofing

Bhujanga Rao: Conceptualization

Corresponding author

Ethics declarations

Ethical approval

NA.

Consent to participate

Yes.

Consent for publication

Yes.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ramesh Babu, B., Rao, A.B. Electromagnetic interference shielding effect of stacked aloe vera, silk fabric, and copper slag–embedded epoxy composite at high-frequency bands. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03852-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03852-3