Abstract

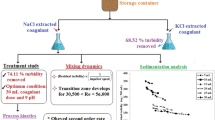

In this study, cashew nut husk was used to prepare agro-based coagulant (Tanhusk). The agro-based coagulant was compared with aluminum sulfate (alum) in the treatment of paint industry effluent (PIE). The effects of parameters such as pH (4–12), contact time (0–60 min), and coagulant dosage (100–500 mg/L) on the effluent decontamination were investigated. Coagulation/flocculation efficiency using Tanhusk was found to increase with contact time and decreasing pH, while alum performed better at alkaline conditions. A comparison of the results gave an efficiency of alum at 91% and Tanhusk at 73.18%. The kinetics of the coagulation and flocculation treatment of PIE using alum and Tanhusk by the integral and particle aggregation were studied. The reaction order kinetics for alum and Tanhusk were second order. The rate constants were 0.00008 L/mg and 0.00005 L/mg min for alum and Tanhusk, respectively. The kinetics of particle aggregation based on Tanhusk bio-coagulant dosage and effluent pH showed that the destabilization of monomers facilitated the forming of dimers and trimers. The study affirmed that the plant-based coagulant Tanhusk can be a potential replacement for alum for the treatment of paint effluent.

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available from the corresponding author upon reasonable request.

References

Shan TC, Al Matar M, Makky EA, Ali EN (2017) Appl Water Sci 7:1369

Chouby S, Rajput SK, Bapat KN (2012) Int J Emerg Technol Adv Eng 2:429

Hendrawati Yuliastri IR, Nurhasni Rohaeti E, Effend H, Darusman LK (2016) The use of Moringa oleifera seed powder as coagulant to improve the quality of wastewater and ground water. IOP Conf Ser: Earth Environ Sci pp 31. https://doi.org/10.1088/1755-1315/31/1/012033

Nnaji PC, Okoye CC, Umeuzuegbu JC (2020) World Sci News 146:184

Kumar P, Prasad B, Chand S (2009) Treatment of desizing wastewater by catalytic thermal treatment and coagulation. J Hazard Mater 163(1):433–440

Sharma BK (2011) Industrial Chemistry, 16th edn. India

Lei L, Hu X, Chen G, Porter JF, Yue PL (2000) Ind Eng Chem Res 39:2896

Menkiti MC, Okoani AO, Ejimofor MI (2018) Appl Water Sci 8:189. https://doi.org/10.1007/s13201-018-0836-1

Wei J, Gao B, Yue Q, Wang Y, Li W, Zhu X (2009) Water Res 43:724–732

Okey-Onyesolu CF, Onukwuli OD, Ejimofor MI, Okoye CC (2020) Heliyon 6:e04468

Zahrim A, Dexter Z, Joseph C, Hilal N (2017) J Water Process Eng 16:258–269

Kumar PS, Karthikeyan R, Anbalagan K, Bhanushali MN (2016) Sep Sci Techol 51:2028–2037

Nnaji NJN, Ani JU, Aneke LE, Onukwuli OD, Okoro UC, Ume JI (1930) J Ind Eng Chem 20:2014

Carnacho FP, Sousa VS, Bergamasco R, Teixeira MR (2017) Chem Eng J 313:2226

Taiwo AS, Adenike K, Aderonke O (2020) Efficacy of a natural coagulant protein from Moringa oleifera (Lam) seeds in treatment of Opa reservoir water. Heliyon, Ile-Ife Nigeria, p e03335

Ezemagu IG, Ejimofor MI, Menkiti MC (2020) Turbidimetric study for the decontamination of paint effluent (PE) using mucuna seed coagulant (MSC): Statistical design and coag-floculation modeling. Environ Adv 2:100023. https://doi.org/10.1016/j.envadv.2020.100023

Okolo BI, Adeyi O, Oke EO, Agu CM, Nnaji PC, Akatobi KN, Onukwuli DO (2021) Scientific African 14:e00959. https://doi.org/10.1016/j.sciaf.2021.e00959

Okorie O, Okonkwo TJN, Nwachukwu N, Okeke I (2010) Potentials of Detarium microcarpum (guill and sperr) seed oil as a matrix for the formulation of haloperidol injection. Int J Pharm Sci Rev & Res 5(1):1–4

Ukoha PO, Ejikeme PM, Maju CC (2008) J Chem Soc Nig 33:152–156

Moreno-Pirajan JC, Rangel D, Amaya B, Vargas EM, Giraldo L (2006) J Argent Chem Soc 94:1–13

Abia AA, Igwe JC, Okparaeke OC (2005) Int J Chem 15:187–191

Bolton KA, Evans LJ (1996) Canadian. J Soil Sci 76:183–189

Zanten JHV, Elimelech M (1992) J Colloid Interface 154:1–7

Olugbenga SB, Mary AO, Abimbola MO (2010) Stem Cell 1:14–30

Ani JU, Nnaji NJN, Okoye COB, Onukwuli OD (2012) J Haz Mat 243:59–66

Okolo BI, Menkiti MC, Nnaji PC, Onukwuli OD, Agu CC (2014) Br J Appl Sci Tech 4:4791

Fogler HS (2006) Elements of Chemical Reaction Engineering, 4th edn. New Jersey, USA

Sun Y, Zhou S, Chiang P, Shah KJ (2019) Water-Energy Nexus 2:25

Vajihinejad V, Gumfekar SP, Bazoubandi B, Najafabadi ZR, Soares JBP (2019) Macromol Mater Eng 304:1800526

Adachi Y, Kobayashi A, Motoyoshi K (2012) Int J Polym Sci 2012:1. https://doi.org/10.1155/2012/574878

Chandrashekar S, Vijayakumar R, Chelliah R, Daliri EB, Madar IH, Sultan G, Rubab M, Elahi F, Yeon S, Oh D (2021) Molecules 26:2080

Kokona B, Rosenthal ZP, Fairman R (2014) The role of the coiled-coil structural motif in polyglutamine aggregation. Biochemistry 53(43):6738–6746. https://doi.org/10.1021/bi500449a

Desta WM, Bote ME (2021) Heliyon 7:e08451

Nnaji PC, Anadebe VC, Ezemagu IG, Onukwuli OD (2022) Arabian J Chem 15:103629

Vishali S, Karthikeyan R (2014) Separat. Sci Technol 49:2510–2517

Abdulsahib HT, Taobi AH, Hashim SS (2015) IJAR 3(2):426–442

Vishali S, Karthikeyan R (2014) Desalin Water Treat 57:13157–13165

Mageshkumar M, Karthikeyan R (2015) Desalin Water Treat 57:14954–14964

Xioying M, Guangming Z, Chang Z, Zisong W, Jian Y, Jianbing I, Guobe H, Hongliag I (2009) J Colloid Interface Sci 337:408–413

Helmut HA, Schmitt AF (1997) J Colloid Interface Sci 192:463–470

Menkiti MC, Onukwuli OD, Igbokwe PK, Ugodulunwa FXO (2008) J Appl Sci 3(4):317–323

Smoluchowski M (1917) VersucheinerMathematischenTheorie der Koagulations Kinetic KolloiderLousungen. Z Phys Chem 92:129–168

Vishali S, Rashmi P, Karthikeyan R (2016) Desalin Water Treat 57:13157–13165

Sami K, Imen K, Ghofrane L, Ahmed G et al (2021) Optimization of coagulation-flocculation process in the treatment of surface water for a maximum dissolved organic matter removal using RSM approach. Water Science and Technology: Water Supply 21(6):3042–3056. https://doi.org/10.2166/ws.2021.070

Menkiti MC, Ndaji RC, Ezemagu IG (2017). Water conserv Sci Eng. https://doi.org/10.1007/s41101-017-0027-1

Smoczynski L, Kalinowski S, Cretescu I, Smoczynski M, Ratnaweera H, Trifescu M, Kosobucka M (2019) Study of sludge particles formed during coagulation of synthetic and municipal wastewater for increasing the sludge dewatering efficiency. Water 11(1):101. https://doi.org/10.3390/w11010101

Okolo BI, Nnaji PC, Menkiti MC, Onukwuli OD (2015) A kinetic investigation of the pulverized okra pod induced coag-flocculation in treatment of paint wastewater. American J Anal Chem 6(07):610–622. https://doi.org/10.4236/ajac.2015.67059

Holtholf H, Egelhaaf SU, Brokovec M, Sharteh-Berger P, Sticher H (1996) J American Chem Soc 12:5541

Torres-Knoop A, Schamboeck V, Govindarajan N, Iedema PD, Kryven I (2021) Effect of different monomer precursors with identical functionality on the properties of the polymer network. Commun Mater 2(50). https://doi.org/10.1038/s43246-021-00154-x

Lovell PA, Schork FJ (2020) Biomacromol 21:4396

Liu J, Xu D, Xia N, Hou K, Chen S, Wang Y, Li Y (2018) Molecules 23:1452. https://doi.org/10.3390/molecules/23061452

Zhang Y, Liu P, Xiao L, Zhang Y, Yang X, Jiang L (2021) Separations 8:105. https://doi.org/10.3390/separations8070105

Park J, Kim Y, Lee C, Kim D, Choi W, Kwon H, Kim J, Wang K, Lee J (2021) Nanomaterials 11:1958. https://doi.org/10.3390/nano11081958

Kricheldorf HR, Sceliga F, Weidner SM (2021) Macromol Chem Phys 222:1. https://doi.org/10.1002/macp.202100010

Marinho R, Horiuchi L, Pires CA (2018) Effect of stirring speed on conversion and time to particle stabilization of poly(vinyl chloride) produced by suspensionpolymerization process at the beginning of reaction. Braz J Chem Eng 35(02):631–640. https://doi.org/10.1590/0104-6632.20180352s20160453

Sahu OP, Chaudhari PK (2013) J Appl Sci Environ Manage 17:241

Miranda R, Latour I, Blanco A (2020). Front Chem. https://doi.org/10.3389/fchem.2020.00027

Sanaz S (2021) Impact of physicochemical properties of lignin-based polymers on their flocculation and adsorption performance Ph. D. thesis. Lakehead University, Ontario, Canada

Sibiya NP, Rathilal S, Tetteh EK (2021). Molecules. https://doi.org/10.3390/molecules26030698

Lopez-Maldonado EA, Orepeza-Guzman MT, Ochie-Teran A (2014). J Chem. https://doi.org/10.1155/2014/969720

Mahmudabadi TZ, Ebrahimi AA, Eslami H, Mokhtari M, Salmani MH, Ghaneian MT, Mohamadzadeh M and Pakdaman M (2018) AMB Express 8. https://doi.org/10.1186/s13568-018-0702-4

Nwabanne JT, Oguegbu AA, Agu CM (2018). Inter J Electrochem. https://doi.org/10.1155/2018/4349639

Acknowledgements

Appreciation is hereby given to the Federal Government of Nigeria for financial support in the experimental work through the Earned Allowances Research Fund. We wish to thank the staff of Sharon Paints Company, Ninth mile, Ngwo, Enugu state, Nigeria, for technical support.

Author information

Authors and Affiliations

Contributions

JUA: conceptualization, methodology, data analysis, writing – review and editing. KGA: writing – review and editing. NJN: data analysis, writing – review and editing. IOO: data analysis, writing – review and editing. SIE: writing – review and editing. ODO: conceptualization and editing. UCO: conceptualization and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ani, J.U., Akpomie, K.G., Nnaji, N.J. et al. Process efficiency and kinetics of coagulation for the decontamination of paint industry effluent using cashew nut husk tannins and alum. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03834-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03834-5