Abstract

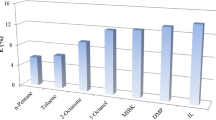

In this work, the reactive extraction of butyric acid (BA) from very dilute aqueous solutions in effluent stream and fermentation broth by using tri-octyl amine (TOA) at different temperatures (298–318 K) in various diluents was investigated. To reduce the toxic effect of TOA and to avoid the harmful effect of decanol on the living microorganism in the bioreactor, nontoxic and green solvents, sunflower and soybean oils were tested as the diluents. The obtained \({K}_{D}^{dil}\) was 2.8–4.2 for decanol, 2.0–4.0 for sunflower oil and 1.3–3.8 for soybean oil. The extraction capacity of the solvents was decreased in the order of decanol > sunflower oil > soybean oil. In chemical extraction, the extraction efficiencies were 85–92% for decanol, 81–91% for sunflower oil and 78–89% soybean oil. The experimentally determined \({K}_{D}^{overall}\) was 4.8–9.5 for decanol, 4.6–8.8 for sunflower oil and 4.5–8.3 for soybean oil. In terms of distribution coefficient and extraction efficiency, decanol showed better recovery of BA than sunflower oil and soybean oil. Overall, the recovery efficiencies using both the edible oils were at per with decanol. Thus, edible oils are suggested to use in the biorefinery industries. The obtained \({\mathrm{K}}_{\mathrm{D}}^{\mathrm{chem}}/{\mathrm{K}}_{\mathrm{D}}^{\mathrm{phy}}\) greater than 1.0 has justified the use of TOA as the reactive extractant. The order of the complex concentration, \({\left[{\left(HA\right)}_{m}{S}_{n}\right]}_{org},\) in different diluents was decanol > sunflower oil > soybean oil. Other important parameters like acid extractant, free acid and dimer concentration at chemical equilibrium state were determined and analysed. The estimated enthalpy change due to mass transfer, \({\left(\Delta H\right)}^{mass tr},\) showed the easiest mixing of the phases in soybean oil. Reaction equilibrium constant, (\({{K}_{E}}_{(m:n)}\)), also followed the above trend of the effects of the diluents with highest for decanol (8.7–4347), intermediate for sunflower oil (6.6–3222) and lowest for soybean oil (5.5–2018). It also diminished with temperature.

Similar content being viewed by others

Abbreviations

- \([S]\) :

-

Concentration of extractant (mol.L−1)

- \([BH]\) :

-

Concentration of acid (mol.L−1)

- \(\left[{B}^{-}\right]\) :

-

Concentration of butyrate ion (mol.L−1)

- \(P\) :

-

Partition coefficient

- \(D\) :

-

Dimer

- \({K}_{D}\) :

-

Distribution coefficient (calculated in terms of mol/L)

- \(E\) :

-

Extraction efficiency

- \({K}_{E}\) :

-

Overall equilibrium complexation constant

- \({K}_{BH}\) :

-

Dissociation constant of butyric acid

- \(m\) :

-

Number of acid molecules

- \(n\) :

-

Number of extractant molecules

- \(Z\) :

-

Loading ratio

- \({z}_{m}\) :

-

Modified loading ratio

- μ:

-

Acid extractant by diluents alone

- ν:

-

Diluents fraction

- \(aq\) :

-

Aqueous solution

- \(org\) :

-

Organic solution

- \(exp\) :

-

Experimental value

- \(\Delta H\) :

-

Enthalpy (KJ/mol)

- \(\Delta S\) :

-

Entropy (J/mol.K)

- \(0\) :

-

Initial concentration of butyric acid

- \(tot\) :

-

Total concentration

- \(free\) :

-

Free acid concentration

- \(dil\) :

-

Diluent

- \(che\) :

-

Chemical

- \(overall\) :

-

Overall acid concentration or distribution coefficient

- \(mod\) :

-

Model value

- \(rxn\) :

-

Reaction

- \(mass tr\) :

-

Mass transfer

References

Wasewar KL (2012) Reactive extraction: an intensifying approach for carboxylic acid separation. Int J Chem Eng Appl 3(4)

Mukherjee S, Munshi B (2020) Experimental and theoretical analysis of reactive extraction of caproic acid by using TBP in green diluents. Chem Eng Process Process Int 153:10792

Li Z, Wei Q, Dai Y (2002) Liquid-liquid equilibria of acetic, propionic, butyric, and valeric acids with trioctylamine as extractant. J Chem Eng Data 47:843–848

Wu X, Li G, Yang H, Zhou H (2015) Study on extraction and separation of butyric acid from clostridium fermentation broth in PEG/Na2SO4 aqueous two-phase system. Fluid Phase Equilib 403:36–42

Vandák D, Zigová J, Sturdik E, Stefan S (1997) Evaluation of solvent and pH for extractive fermentation of butyric acid. Process Biochem 32:245–251

Zigová J, Ernest Sturdík E, Vandák D, Schlosser S (1999) Butyric acid production by Clostridium butyricum with integrated extraction and pertraction. Process Biochem 34:835–843

Atasoy M, Cetecioglu Z (2020) Butyric acid dominant volatile fatty acids production: bio-augmentation of mixed culture fermentation by Clostridium butyricum. J Environ Chem Eng 8:104496

Wu Z, Yang S (2003) Extractive fermentation for butyric acid production from glucose by Clostridium tyrobutyricum. Biotechnol Bioeng 82(1):93–102

Baroi GN, Skiadas IV, Westermann P, Gavala HN (2015) Effect of in situ acids removal on mixed glucose and xylose fermentation by Clostridium tyrobutyricum. AMB Express 5(67):1–9

Jiang L, Wang J, Liang S, Wang X, Cen P, Xu Z (2010) Production of butyric acid from glucose and xylose with immobilized cells of Clostridium tyrobutyricum in a fibrous-bed bioreactor. Appl Biochem Biotechnol 160:350–359

Ahmad A, Ghufran R, Wahid ZA (2012) Effect of cod loading rate on an upflow anaerobic sludge blanket reactor during anaerobic digestion of palm oil mill effluent with butyrate. J Environ Eng Landsc Manag 20(4):256–264

Murtaugh JJ, Bunch RL (1965) Acidic components of sewage effluents and river water. Journal (Water Pollut Control Fed) 37(3):410–415

Reyhanitash E, Kersten SRA, Schuur B (2017) Recovery of volatile fatty acids from fermented wastewater by adsorption. Sus Chem Eng 5:9176–9184

Mamimin C, Prasertsan P, Kongjan P, O-Thong S (2017) Effects of volatile fatty acids in biohydrogen effluent on biohythane production from palm oil mill effluent under thermophilic condition. Electr J Biotechnol 29:78–85

Parchami M, Wainaina S, Mahboubi A, I’Ons D, Taherzadeh MJ (2020) MBR-assisted VFAs production from excess sewage sludge and food waste slurry for sustainable wastewater treatment. Appl Sci 10(2921):1–20

Kurniawan A, Kwon SY, Shin J, Hur J, Cho J (2016) Acid fermentation process combined with post denitrification for the treatment of primary sludge and wastewater with high strength nitrate. Water Res 8(117):1–11

Cadavid-Rodriguez LS, Horan NJ (2014) Production of volatile fatty acids from wastewater screenings using a leach-bed reactor. Water Res 60:242–249

Fu B, Zhang J, Fan J, Wang J, Liu H (2012) Control of C/N ratio for butyric acid production from textile wastewater sludge by anaerobic digestion. Water Sci Technol 65(5):883–889

Welsh FW, Williams RE (1989) The use of vegetable oils to recover compounds from aqueous solutions. J Chem Technol Biotechnol 46:169–178

Yang ST, White AS, Hsu ST (1991) “Extraction of carboxylic acids with tertiary and quaternary amines: Effect of pH. Ind Eng Chem Res 30(6)

Zigová J, Vandák D, Štefan S, Šturdik E (1996) Extraction equilibria of butyric acid with organic solvents. Sep Sci Technol 31(19):2671–2684

Keshav A, Wasewar KL, Chand S (2009) Extraction of acrylic, propionic, and butyric acid using Aliquat 336 in oleyl alcohol: equilibria and effect of temperature. Ind Eng Chem Res 48:888–893

Sabolovẚ E, Schlosser Ṧ, Marẚtk J (2001) Liquid-liquid equilibria of butyric acid in water + solvent systems with trioctylamine as extractant. J Chem Eng Data 46:735–745

Keshav A, Wasewar KL, Chand S (2009) Reactive extraction of propionic acid using tri-n-octylamine, tri-n-butyl phosphate and aliquat 336 in sunflower oil as diluent. J Chem Technol Biotechnol 84:484–489

Pandey S, Jaiswal A, Sohane A, Patle DS, Kumar S (2021) Experimental and theoretical equilibrium insights in the reactive extraction of pinelic acid with tri-n-octylamine in natural solvents. Ind Eng Chem Res 60:18073–18085

Kumar S, Datta D, Babu BV (2011) Estimation of equilibrium parameters using differential evolution in reactive extraction of propionic acid by tri-n-butyl phosphate. Chem Eng Process Process Intensific 50:614–622

Ayan E, Baylan N, Çehreli S (2020) Optimization of reactive extraction of propionic acid with ionic liquids using central composite design. Chem Eng Res Des 666–676

Bilgin M, Kırbaṧlar SỈ, Ṏzcan Ỡ, Dramur U (2006) Distribution of butyric acid between water and several solvents. J Chem Eng Data 51:1546–1550

Mukherjee S, Negi D, Nagraj MS, Munshi B (2021) Reactive extraction of of butyric acid from water using tri-octyl amine in 1-decanol and green natural oils. J Chem Eng Data 66:2733–2753

Acknowledgements

We acknowledged the NIT Rourkela for the infrastructural and analytical facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Consent to participate

All authors have participated in (a) conception and design or analysis and interpretation of the data, (b) drafting the article or revising it critically for important intellectual content and (c) approval of the final version.

Consent for publication

This manuscript has not been submitted to, nor is under review at, another journal or other publishing venue.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mukherjee, S., Munshi, B. Reactive extraction of butyric acid from effluent streams and fermentation broth by using tri-n-octyl amine in decanol/natural oils. Biomass Conv. Bioref. 14, 3439–3451 (2024). https://doi.org/10.1007/s13399-022-02504-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02504-2