Abstract

Butyric acid has many applications in chemical, food, and pharmaceutical industries. In the present study, Clostridium tyrobutyricum ATCC 25755 was immobilized in a fibrous-bed bioreactor to evaluate the performance of butyrate production from glucose and xylose. The results showed that the final concentration and yield of butyric acid were 13.70 and 0.46 g g−1, respectively, in batch fermentation when 30 g L−1 glucose was introduced into the bioreactor. Furthermore, high concentration 10.10 g L−1 and yield 0.40 g g−1 of butyric acid were obtained with 25 g L−1 xylose as the carbon source. The immobilized cells of C. tyrobutyricum ensured similar productivity and yield from repeated batch fermentation. In the fed-batch fermentation, the final concentration of butyric acid was further improved to 24.88 g L−1 with one suitable glucose feeding in the fibrous-bed bioreactor. C. tyrobutyricum immobilized in the fibrous-bed bioreactor would provide an economically viable fermentation process to convert the reducing sugars derived from plant biomass into the final bulk chemical (butyric acid).

Similar content being viewed by others

References

Perlack, R. D., et al. (2005). Biomass as feedstock for a bioenergy and bioproducts industry: The technical feasibility of a billion-ton annual supply (Oak Ridge National Laboratory Report TM-2005, under contract DOE/GO-102005–2135, Oak Ridge, TN

Nonhebel, S. (2005). Renewable energy and food supply: Will there be enough land? Renewable & Sustainable Energy Reviews, 9, 191–201. doi:10.1016/j.rser.2004.02.003.

Somerville, C. (2007). Biofuels. Current Biology, 17, 115–119. doi:10.1016/j.cub.2007.01.010.

Lin, Y., & Tanaka, S. (2006). Ethanol fermentation from biomass resources: Current state and prospects. Applied Microbiology and Biotechnology, 69, 627–642. doi:10.1007/s00253-005-0229-x.

Watson, R., Wright, C. J., McBurney, T., Taylor, A. J., & Linforth, R. S. T. (2002). Influence of harvest data and light integral on the development of strawberry flavor compounds. Journal of Experimental Botany, 53(377), 2121–2129. doi:10.1093/jxb/erf088.

Beyer-Sehlmeyer, G., Glei, M., Hartmann, E., Hughes, R., Persin, C., Böhm, V., et al. (2003). Butyrate is only one of several growth inhibitors produced during gut flora-mediated fermentation of dietary fiber sources. The British Journal of Nutrition, 90, 1057–1070. doi:10.1079/BJN20031003.

Chen, Z.-X., & Breitman, T. R. (1994). Tributyrin: A prodrug of butyric acid for potential clinical application in differentiation therapy. Cancer Research, 54, 3494–3499.

Pouillart, P. R. (1998). Role of butyric acid and its derivatives in the treatment of colorectal cancer and hemoglobinopathies. Life Sciences, 63(20), 1739–1760. doi:10.1016/S0024-3205(98)00279-3.

Williams, E. A., Coxhead, J. M., & Mathers, J. C. (2003). Anti-cancer effects of butyrate: Use of micro-array technology to investigate mechanisms. The Proceedings of the Nutrition Society, 62, 107–115. doi:10.1079/PNS2002230.

Rephaeli, A., Zhuk, R., & Nudelman, A. (2000). Prodrugs of butyric acid from bench to bedside: Synthetic design, mechanisms of action, and clinical applications. Drug Development Research, 50, 379–391. doi:10.1002/1098-2299(200007/08)50:3/4<379::AID-DDR20>3.0.CO;2-8.

Playne, M. J. (1985). Propionic and butyric acids. In M. Moo-Young (Ed.), Comprehensive Biotechnology (pp. 731–759). Oxford, UK: Pergamon.

Sneath, P. H. A. (1986). Genus clostridium. In J. G. Holt (Ed.), Bergey’s manual of systematic bacteriology 2/12–13 (pp. 1141–1200). Baltimore: Waverly Press.

Michel-Savin, D., Marchal, R., & Vandecasteele, J. P. (1990a). Control of the selectivity of butyric acid production and improvement of fermentation performance with Clostridium tyrobutyricum. Applied Microbiology and Biotechnology, 32, 387–392. doi:10.1007/BF00903770.

Michel-Savin, D., Marchal, R., & Vandecasteele, J. P. (1990b). Butyrate production in continuous culture of Clostridium tyrobutyricum: Effect of end-product inhibition. Applied Microbiology and Biotechnology, 33, 127–131. doi:10.1007/BF00176512.

Ramey, D., & Yang, S. T. (2005). Production of butyric acid and butanol from biomass. Morgantown, WV.

Liu, X., & Yang, S. T. (2006). Kinetics of butyric acid fermentation of glucose and xylose by Clostridium tyrobutyricum wild type and mutant. Process Biochemistry, 41, 801–808. doi:10.1016/j.procbio.2005.10.009.

Najafpour, G. D. (2006). Immobilization of microbial cells for the production of organic acid and ethanol. Biochemical Engineering and Biotechnology, 8, 199–227.

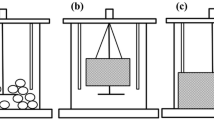

Huang, Y., Wu, Z., Cheung, C., & Yang, S. T. (2002). Production of carboxylic acids from hydrolyzed corn meal by immobilized cell fermentation in a fibrous-bed bioreactor. Bioresource Technology, 82(1), 51–59. doi:10.1016/S0960-8524(01)00151-1.

Huang, Y., & Yang, S. T. (1998). Acetate production from whey lactose using co-immobilized cells of homolactic and homoacetic bacteria in a fibrous-bed bioreactor. Biotechnology and Bioengineering, 60, 499–507. doi:10.1002/(SICI)1097-0290(19981120)60:4<498::AID-BIT12>3.0.CO;2-E.

Yang, S. T. (1996). Extractive fermentation using convoluted fibrous bed bioreactor. US Patent No. 5,563,069.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugars. Analytical Chemistry, 31, 426–428. doi:10.1021/ac60147a030.

He, G., Kong, Q., Chen, Q., & Ruan, H. (2005). Batch and fed-batch production of butyric acid by Clostridium butyricum ZJUCB. Journal of Zhejiang University. Science, 11, 1076–1080. doi:10.1631/jzus.2005.B1076.

El Kanouni, A., Zerdani, S., Zaafa, S., Znassni, M., Loutfi, M., & Boudouma, M. (1998). The improvement of glucose/xylose fermentation by Clostridium acetobutylicum using calcium carbonate. World Journal of Microbiology & Biotechnology, 14, 431–435. doi:10.1023/A:1008881731894.

Heyndrickx, M., De Vos, P., & De Ley, J. (1991). Fermentation of D-xylose by Clostridium butyricum LMG 1213t1 in chemostats. Enzyme and Microbial Technology, 13, 893–897. doi:10.1016/0141-0229(91)90105-J.

Acknowledgements

This work was supported by a grant from the Ministry of Science and Technology of China (National Basic Research Program of China, 2007CB707805).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jiang, L., Wang, J., Liang, S. et al. Production of Butyric Acid from Glucose and Xylose with Immobilized Cells of Clostridium tyrobutyricum in a Fibrous-bed Bioreactor. Appl Biochem Biotechnol 160, 350–359 (2010). https://doi.org/10.1007/s12010-008-8305-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8305-1