Abstract

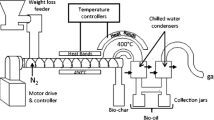

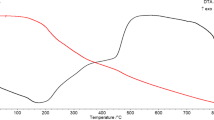

Wastes from oil palm plantations and mill processing are renewable resources for bio-energy and biochemicals development. The five most abundant oil palm wastes are empty fruit bunch (EFB), palm kernel shell (PKS), palm mesocarp fiber (PMF), palm frond (PF), and palm trunk (PT). These different types of biomass have different properties which can significantly influence the bio-oil products and pyrolysis performance. Bio-oil and biochar were produced by slow pyrolysis of these wastes in a fixed-bed reactor at 600 °C for 60 min. The biomass and pyrolysis products were comparatively characterized using thermogravimetric analysis (TGA), elemental analysis, Fourier transform infrared spectroscopy (FTIR), gas chromatography-mass spectrometry (GC–MS), and scanning electron microscopy (SEM). The highest yield (25.5 wt%) of bio-oil was obtained from PF, while the highest yield (29.7 wt%) of biochar was obtained from PMF. Fatty acids were the main compounds in bio-oil obtained from EFB and PMF, while those from PKS, PF, and PT contained more aromatics and their boiling point distributions were lower than EFB and PMF bio-oils. Biochar from all the materials decomposed in two stages and showed similar compositions. The variations in the yields and properties of products resulted from differences in the properties of feedstocks. The results could contribute useful data for selection and controlling the pyrolysis of oil palm wastes.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article (and its supplementary information files).

References

FAOSTAT (2019) Crops, Food and Agriculture Organization of the United Nations, Rome. http://www.fao.org/faostat/en/#data/QC. Accessed 4 July, 2021

FAOSTAT (2010) Crops, Food and Agriculture Organization of the United Nations, Rome. http://www.fao.org/faostat/en/#data/QC. Accessed 4 July, 2021

OAE (2019) Palm oil, Office of Agricultural Econimics. https://www.oae.go.th. Accessed 4 July, 2021

Chavalparit O, Rulkens WH, Mol APJ, Khaodhair S (2006) Options for environmental sustainability of the crude palm oil industry in Thailand through enhancement of industrial ecosystems. Environ Dev Sustain 8:271–287. https://doi.org/10.1007/s10668-005-9018-z

Abnisa F, Arami-Niya A, Wan Daud WMA, Sahu JN, Noor IM (2013) Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis. Energ Convers Manage 76:1073–1082. https://doi.org/10.1016/j.enconman.2013.08.038

Hambali E, Rivai M (2017) The potential of palm oil waste biomass in Indonesia in 2020 and 2030. IOP Conf Ser: Earth Environ Sci 65:012050. https://doi.org/10.1088/1755-1315/65/1/012050

Poh PE, Wu TY, Lam WH, Poon WC, Lim CS (2020) Oil palm plantation wastes. In: Waste management in the palm oil industry plantation and milling processes. Springer Nature Switzerland AG, Switzerland. https://doi.org/10.1007/978–3–030–39550–6_2

Danylo O, Pirker J, Lemoine G, Ceccherini G, See L, McCallum I, Hadi KF, Achard F, Fritz S (2021) A map of the extent and year of detection of oil palm plantations in Indonesia. Malaysia and Thailand Sci Data 8:96. https://doi.org/10.1038/s41597-021-00867-1

Vu HP, Nguyen LN, Vu MT, Hasan Johir MA, McLaughlan R, Nghiem LD (2020) A comprehensive review on the framework to valorize lignocellulosic biomass as biorefinery feedstocks. Sci Total Environ 743:140630. https://doi.org/10.1016/j.scitotenv.2020.140630

Phusunti N, Cheirsilp B (2020) Integrated protein extraction with bio-oil production for microalgal biorefinery. Algal Res 48:101918. https://doi.org/10.1016/j.algal.2020.101918

Saeaung K, Phusunti N, Phetwarotai W, Assabumrungrat S, Cheirsilp B (2021) Catalytic pyrolysis of petroleum-based and biodegradable plastic waste to obtain high-value chemicals. Waste manage 127:101–111. https://doi.org/10.1016/j.wasman.2021.04.024

Czajczyńska D, Anguilano L, Ghazal H, Krzyżyńska R, Reynolds AJ, Spencer N, Jouhara H (2017) Potential of pyrolysis processes in the waste management sector. Therm Sci Eng Prog 3:171–197. https://doi.org/10.1016/j.tsep.2017.06.003

Kan T, Strezov V, Evans TJ (2016) Lignocellulosic biomass pyrolysis: a review of product properties and effects of pyrolysis parameters. Renew Sust Energ Rev 57:1126–1140. https://doi.org/10.1016/j.rser.2015.12.185

Abnisa F, Arami-Niya A, Daud WMAW, Sahu JN (2013) Characterization of bio-oil and bio-char from pyrolysis of palm oil wastes. Bioenerg Res 6:830–840. https://doi.org/10.1007/s12155-013-9313-8

Yang H, Yan R, Chen H, Lee DH, Liang DT, Zheng C (2006) Mechnaism of palm oil waste pyrolysis in a packed bed. Energ Fuel 20:1321–1328. https://doi.org/10.1021/ef0600311

Lee XJ, Lee LY, Gan S, Thangalazhy-Gopakumar S, Ng HK (2017) Biochar potential evaluation of palm oil wastes through slow pyrolysis: thermochemical characterization and pyrolytic kinetic studies. Bioresource Technol 236:155–163. https://doi.org/10.1016/j.biortech.2017.03.105

Yakub MI, Abdalla AY, Feroz KK, Suzana Y, Ibraheem A, Chin SA (2015) Pyrolysis of oil palm residues in a fixed bed tubular reactor. JPEE 3:185–193. https://doi.org/10.4236/jpee.2015.34026

Mostafazadeh AK, Solomatnikova O, Drogui P, Tyagi RD (2018) A review of recent research and developments in fast pyrolysis and bio-oil upgrading. Biomass Conv Bioref 8:739–773. https://doi.org/10.1007/s13399-018-0320-z

Dada TK, Sheehan M, Murugavelh S, Antunes E (2021) A review on catalytic pyrolysis for high-quality bio-oil production from biomass. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-01391-3

Dhyani V, Bhaskar T (2018) A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew Energ 129:695–716. https://doi.org/10.1016/j.renene.2017.04.035

Nanda S, Dalai AK, Berruti F, Kozinski JA (2016) Biochar as an exceptional bioresource for energy, agronomy, carbon sequestration, activated carbon and specialty materials. Waste Biomass Valor 7:201–235. https://doi.org/10.1007/s12649-015-9459-z

Friedl A, Padouvas E, Rotter H, Varmuza K (2005) Prediction of heating values of biomass fuel from elemental composition. Anal Chim Acta 544:191–198. https://doi.org/10.1016/j.aca.2005.01.041

Loh SK (2017) The potential of the Malaysian oil palm biomass as a renewable energy source. Energ Convers Manage 141:285–298. https://doi.org/10.1016/j.enconman.2016.08.081

González JF, Ledesma B, Alkassir A, González J (2011) Study of the influence of the composition of several biomass pellets on the drying process. Biomass Bioenerg 35:4399–4406. https://doi.org/10.1016/j.biombioe.2011.08.019

Bryś A, Bryś J, Ostrowska-Ligęza E, Kaleta A, Górnicki K, Głowacki S, Koczoń P (2016) Wood biomass characterization by DSC or FT-IR spectroscopy. J Therm Anal Calorim 126:27–35. https://doi.org/10.1007/s10973-016-5713-2

Demirbas A (2007) Effects of moisture and hydrogen content on the heating value of fuels. Energ Source Part A 29:649–655. https://doi.org/10.1080/009083190957801

Bain RL (1993) Electricity from biomass in the United States: status and future direction. Bioresource Technol 46:86–93. https://doi.org/10.1016/0960-8524(93)90058-J

Mishra RK, Mohanty K (2018) Characterization of non-edible lignocellulosic biomass in terms of their candidacy towards alternative renewable fuels. Biomass Conv Bioref 8:799–812. https://doi.org/10.1007/s13399-018-0332-8

Asadullah M, Rasid NSA, Kadir SASA, Azdarpour A (2013) Production and detailed characterization of bio-oil from fast pyrolysis of palm kernel shell. Biomass Bioenerg 59:316–324. https://doi.org/10.1016/j.biombioe.2013.08.037

Chan YH, Quitain AT, Yusup S, Uemura Y, Sasaki M, Kida T (2018) Liquefaction of palm kernel shell in sub- and supercritical water for bio-oil production. J Energy Inst 91:721–732. https://doi.org/10.1016/j.joei.2017.05.009

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Bilba K, Ouensanga A (1996) Fourier transform infrared spectroscopic study of thermal degradation of sugar cane bagasse. J Anal Appl Pyrol 38:61–73. https://doi.org/10.1016/S0165-2370(96)00952-7

Williams CL, Westover TL, Emerson RM, Tumuluru JS, Li C (2016) Sources of biomass feedstock variability and the potential impact on biofuels production. Bioenerg Res 9:1–14. https://doi.org/10.1007/s12155-015-9694-y

Yan J, Oyedeji O, Leal JH, Donohoe BS, Semelsberger TA, Li C, Hoover AN, Webb E, Bose EA, Zeng Y, Williams CL, Schaller KD, Sun N, Ray AE, Tanjore D (2020) Characterizing variability in lignocellulosic biomass: a review. ACS Sustainable Chem Eng 8(22):8059–8085. https://doi.org/10.1021/acssuschemeng.9b06263

Hussain M, Zabiri H, Tufa LD, Yusup S, Ali I (2019) A kinetic study and thermal decomposition characteristics of palm kernel shell using model-fitting and model-free methods. Biofuels :1–12. https://doi.org/10.1080/17597269.2019.1642642

Sengpracha W, Agustin MB, Phutdhawong W (2012) A survey on the fatty acid composition of commercial palm oil in Thailand. Chem Sci Trans 1:612–617. https://doi.org/10.7598/cst2012.258

Chavarro Gomez J, Mokhtar MN, Sulaiman A, Samsu Baharuddin A, Busu Z (2015) Recovery of residual crude palm oil from the empty fruit bunch spikelets using environmentally friendly processes. Sep Sci Technol 50:1677–1683. https://doi.org/10.1080/01496395.2014.994781

Lau HLN, Choo YM, Ma AN, Chuah CH (2006) Quality of residual oil from palm-pressed mesocarp fiber (Elaeis guineensis) using supercritical CO2 with and without ethanol. J Amer Oil Chem Soc 83:893–898. https://doi.org/10.1007/s11746-006-5043-9

Bakar AA, Hassan A, Yusof AFM (2006) The effect of oil extraction of the oil palm empty fruit bunch on the processability, impact, and flexural properties of PVC-U composites. Int J Polym Mater 55:627–641. https://doi.org/10.1080/00914030500306446

Kok S, Ong-Abdullah M, Chenglian Ee G, Namasivayam P (2011) Comparison of nutrient composition in kernel of tenera and clonal materials of oil palm (Elaeis guineensis Jacq.). Food Chem 129:1343–1347. https://doi.org/10.1016/j.foodchem.2011.05.023

Shrivastava P, Kumar A, Tekasakul P, Lam SS, Palamanit (2021) Comparative investigation of yield and quality of bio-oil and biochar from pyrolysis of woody and non-woody biomasses. Energies 14:1092. https://doi.org/10.1080/00914030500306446

Sareekam N, Kamurudin SK, Kasmuri NH (2016) Optimization of bio oil from palm oil fronds via fast pyrolysis. Indian J Sci Technol 9:1–13. https://doi.org/10.17485/ijst/2016/v9i21/95232

Zhao C, Jiang E, Chen A (2017) Volatile production from pyrolysis of cellulose, hemicellulose and lignin. J Energy Inst 90:902–913. https://doi.org/10.1016/j.joei.2016.08.004

Stefanidis SD, Kalogiannis KG, Iliopoulou EF, Michailof CM, Pilavachi PA, Lappas AA (2014) A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J Anal Appl Pyrolysis 105:143–150. https://doi.org/10.1016/j.jaap.2013.10.013

Omar S, Alsamaq S, Yang Y, Wang J (2019) Production of renewable fuels by blending bio-oil with alcohols and upgrading under supercritical conditions. Front Chem Sci Eng 13:702–717. https://doi.org/10.1007/s11705-019-1861-9

Demirbas A (2009) Pyrolysis mechanisms of biomass materials. Energ Source Part A 31:1186–1193. https://doi.org/10.1080/15567030801952268

Mu W, Ben H, Ragauskas A, Deng Y (2013) Lignin pyrolysis components and upgrading — technology review. Bioenerg Res 6:1183–1204. https://doi.org/10.1007/s12155-013-9314-7

Chen W-H, Lin Y-Y, Liu H-C, Chen T-C, Hung H-C, Chen C-H (2019) Analysis of physicochemical properties of liquefaction bio-oil from food waste. Energy Procedia 158:61–66. https://doi.org/10.1016/j.egypro.2019.01.036

Aslam M, Kothiyal NC, Sarma AK (2015) True boiling point distillation and product quality assessment of biocrude obtained from Mesua ferrea L. seed oil via hydroprocessing. Clean Techn Environ Policy 17:175–185. https://doi.org/10.1007/s10098-014-0774-z

Haarlemmer G, Guizani C, Anouti S, Déniel M, Roubaud A, Valin S, Analysis and comparison of bio-oils obtained by hydrothermal liquefaction and fast pyrolysis of beech wood. Fuel 174:180–188. https://doi.org/10.1016/j.fuel.2016.01.082

Mohan D, Pittman CU Jr, Steele PH (2006) Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuels 20:848–889. https://doi.org/10.1021/ef0502397

Wang Y, Li X, Mourant D, Gunawan R, Zhang S, Li C-Z (2012) Formation of aromatic structures during the pyrolysis of bio-oil. Energ Fuel 26:241–247. https://doi.org/10.1016/j.fuel.2012.11.052

Al-Wabel MI, Al-Omran A, El-Naggar AH, Nadeem M, Usman ARA (2013) Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresource Technol 131:374–379. https://doi.org/10.1016/j.biortech.2012.12.165

Lee Y, Park J, Ryu C, Gang KS, Yang W, Park Y-K, Jung J, Hyun S (2013) Comparison of biochar properties from biomass residues produced by slow pyrolysis at 500 °C. Bioresource Technol 148:196–201. https://doi.org/10.1016/j.biortech.2013.08.135

Soh M, Khaerudini DS, Chew JJ, Sunarso J (2021) Wet torrefaction of empty fruit bunches (EFB) and oil palm trunks (OPT): effects of process parameters on their physicochemical and structural properties. S Afr J Chem Eng 35:126–136. https://doi.org/10.1016/j.sajce.2020.09.004

Oliveira FR, Patel AK, Jaisi DP, Adhikari S, Lu H, Khanal SK (2017) Environmental application of biochar: Current status and perspectives. Bioresour Technol 246:110–122. https://doi.org/10.1016/j.biortech.2017.08.122

Lyu H, Zhang Q, Shen B (2020) Application of biochar and its composites in catalysis. Chemosphere 240:124842. https://doi.org/10.1016/j.chemosphere.2019.124842

Liu Z, Han G (2015) Production of solid fuel biochar from waste biomass by low temperature pyrolysis. Fuel 158:159–165. https://doi.org/10.1016/j.fuel.2015.05.032

Acknowledgements

The authors would like to thank Mr.Thomas Coyne for assistance with the English text.

Funding

This research was supported by National Science, Research and Innovation Fund (NSRF) and Prince of Songkla University (Grant Nos. SCI6505114M and SCI6505114e) and the Faculty of Science Research Fund, Prince of Songkla University, Contract no.1–2559-02–001. Facility support from the Center of Excellence for Innovation in Chemistry (PERCH-CIC), Ministry of Higher Education, Science, Research and Innovation is also received. The authors are supported by Thailand Research Fund under Grant No. RTA6280014. The authors would like to thank Mr.Thomas Coyne for assistance with the English text.

Author information

Authors and Affiliations

Contributions

Conceptualization: Neeranuch Phusunti, Worasak Phetwarotai; Methodology: Yanisa Chantanumat, Neeranuch Phusunti, Silawan Sangthong; Formal analysis and investigation: Neeranuch Phusunti, Yanisa Chantanumat, Worasak Phetwarotai, Silawan Sangthong, Muhammad Saifullah Abu Bakar, Arkom Palamanit; Writing—original draft preparation: Neeranuch Phusunti, Worasak Phetwarotai; Writing — review and editing: Neeranuch Phusunti, Worasak Phetwarotai; Funding acquisition: Neeranuch Phusunti, Benjamas Cheirsilp; Resources: Arkom Palamanit; Supervision: Benjamas Cheirsilp.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chantanumat, Y., Phetwarotai, W., Sangthong, S. et al. Characterization of bio-oil and biochar from slow pyrolysis of oil palm plantation and palm oil mill wastes. Biomass Conv. Bioref. 13, 13813–13825 (2023). https://doi.org/10.1007/s13399-021-02291-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02291-2