Abstract

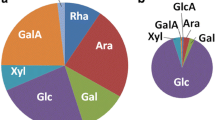

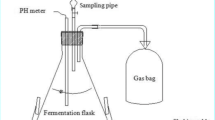

Biofuels, derived from sustainable biomass feedstock, are promising alternatives for fossil derivative fuels to mitigate climate change and air pollution. The molecular structure of lignocellulosic biomass, which creates the limitation of utilization by microorganisms, can be degraded to fermentable sugar via a pre-treatment process. In this study, citric acid as a weak acid and sulfuric acid as a strong acid were used for the pre-treatment of sugar beet pulp under pressure and non-pressure conditions. Fermentable sugar amount was determined for total sugar and reduced sugar formation. Acid ratio, solid ratio and reaction time variables were optimized for the highest fermentable sugar concentration via Box-Behnken statistical methods. Finally, pressure is significantly increasing the strong acid effect, where the total sugar can reach up to 33 g/L at 4% acid ratio, 27.5-min reaction time, and 5% solid ratio. A 27.5-min reaction time gives 11 g/L total sugar concentration under pressure conditions at 5% citric acid ratio. The highest reduced sugar concentration is 1170 mg/L for sulfuric acid under pressure with only 3% solid ratio. SEM–EDX and FT-IR analysis show reliable degradation of molecular structure. SEM analysis showed that under the same conditions at 100 °C and 1 atm, sulfuric acid produced a much more intense deformation than citric acid, with more fragmentation occurring on the surface parallel to the TS. In addition, protein analysis obtained using Aspergillus niger in microbial cultivation experiments supports that pre-treatment products may be suitable for biofuel production and microbial use. The highest protein value obtained by sulfuric acid pre-treatment is 120 mg/L. Pre-treatment is necessary for the development of microbial activity in the production of biofuels from agricultural wastes. The total protein content is an important parameter in determining total enzyme production in monitoring microbial growth.

Similar content being viewed by others

References

Balali Y, Stegen S (2021) Review of energy storage systems for vehicles based on technology, environmental impacts, and costs. Renew Sustain Energy Rev 135, https://doi.org/10.1016/j.rser.2020.110185

Arpia AA, Chen W-H, Lam SS, Rousset P, de Luna MDG (2021) Sustainable biofuel and bioenergy production from biomass waste residues using microwave-assisted heating: a comprehensive review. Chem Eng J 403, https://doi.org/10.1016/j.cej.2020.126233

Cheah WY, Sankaran R, Show PL, Ibrahim TNBT, Chew KW, Culaba A, Chang J-S (2020) Pretreatment methods for lignocellulosic biofuels production: current advances, challenges and future prospects. Biofuel Res J 7, 1115–1127. https://doi.org/10.18331/BRJ2020.7.1.4

Zhao J, Xu Y, Wang W, Griffin J, Roozeboom K, Wang D (2020) Bioconversion of industrial hemp biomass for bioethanol production: a review. Fuel 281, https://doi.org/10.1016/j.fuel.2020.118725

Branco RHR, Serafim LS, Xavier AMRB (2019) Second generation bioethanol production: on the use of pulp and paper industry wastes as feedstock. Fermentation 5, https://doi.org/10.3390/fermentation5010004

Smuga-Kogut M, Piskier T, Walendzik B, Szymanowska-Powałowska D (2019) assessment of wasteland derived biomass for bioethanol production. Electron J Biotechnol 41:1–8. https://doi.org/10.1016/j.ejbt.2019.05.001

Adıgüzel AO, Tunçer M (2017) Purification and characterization of cutinase from Bacillus sp. KY0701 isolated from plastic wastes. Prep Biochem Biotechnol 47:925–933. https://doi.org/10.1080/10826068.2017.1365245

Sahu S, Pramanik K (2018) Evaluation and optimization of organic acid pretreatment of cotton gin waste for enzymatic hydrolysis and bioethanol production. Appl Biochem Biotechnol 186:1047–1060. https://doi.org/10.1007/s12010-018-2790-7

Kootstra AMJ, Beeftink HH, Scott EL, Sanders JPM (2009) Comparison of dilute mineral and organic acid pretreatment for enzymatic hydrolysis of wheat straw. Biochem Eng J 46:126–131. https://doi.org/10.1016/J.BEJ.2009.04.020

Kuo P-C, Yu J (2020) Process simulation and techno-economic analysis for production of industrial sugars from lignocellulosic biomass. Ind Crops Prod 155 https://doi.org/10.1016/j.indcrop.2020.112783

Gomes MG, Gurgel LVA, Baffi MA, Pasquini D (2020) Pretreatment of sugarcane bagasse using citric acid and its use in enzymatic hydrolysis. Renew Energy 157:332–341. https://doi.org/10.1016/j.renene.2020.05.002

Greetham D, Adams JM, Du C (2020) The utilization of seawater for the hydrolysis of macroalgae and subsequent bioethanol fermentation. Sci Rep 10. https://doi.org/10.1038/s41598-020-66610-9

Zhang Y, Wang L, Li T, Shen Y, Luo J (2020) Acid soaking followed by steam flash-explosion pretreatment to enhance saccharification of rice husk for poly(3-hydroxybutyrate) production. Int J Biol Macromol 160:446–455. https://doi.org/10.1016/j.ijbiomac.2020.05.218

Kamzon MA, Abderafi S, Bounahmidi T (2021) Multi-objective optimization of the first stage dilute sulfuric acid hydrolysis of Moroccan beet pulp. Biomass Convers Biorefinery 2021:1–17. https://doi.org/10.1007/S13399-021-01475-0

Li G, Sun Y, Guo W, Yuan L (2018) Comparison of various pretreatment strategies and their effect on chemistry and structure of sugar beet pulp. J Clean Prod 181:217–223. https://doi.org/10.1016/J.JCLEPRO.2018.01.259

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318. https://doi.org/10.1016/j.biortech.2018.04.099

Toscan A, Morais ARC, Paixão SM, Alves L, Andreaus J, Camassola M, Dillon AJP, Lukasik RM (2017) High-pressure carbon dioxide/water pre-treatment of sugarcane bagasse and elephant grass: assessment of the effect of biomass composition on process efficiency. Bioresour Technol 224:639–647. https://doi.org/10.1016/j.biortech.2016.11.101

Du S-K, Su X, Yang W, Wang Y, Kuang M, Ma L, Fang D, Zhou D (2016) Enzymatic saccharification of high pressure assist-alkali pretreated cotton stalk and structural characterization. Carbohydr Polym 140:279–286. https://doi.org/10.1016/j.carbpol.2015.12.056

Islam SMM, Li Q, Loman AA, Ju L-K (2017) CO<inf>2</inf>-H<inf>2</inf>O based pretreatment and enzyme hydrolysis of soybean hulls. Enzyme Microb Technol 106, 18–27. https://doi.org/10.1016/j.enzmictec.2017.06.011

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275. https://doi.org/10.1016/s0021-9258(19)52451-6

Sidi-Yacoub B, Oudghiri F, Belkadi M (2019) Rocío Rodríguez-Barroso, •: Characterization of lignocellulosic components in exhausted sugar beet pulp waste by TG/FTIR analysis. J Therm Anal Calorim 138:1801–1809. https://doi.org/10.1007/s10973-019-08179-8

Li M, Wang LJ, Li D, Cheng YL, Adhikari B (2014) Preparation and characterization of cellulose nanofibers from de-pectinated sugar beet pulp. Carbohydr Polym 102:136–143. https://doi.org/10.1016/j.carbpol.2013.11.021

Harifi-Mood AR, Hadavand-Mirzaie F (2015) Adsorption of basic violet 16 from aqueous solutions by waste sugar beet pulp: kinetic, thermodynamic, and equilibrium isotherm studies. Chem Speciat Bioavailab 27:8–14. https://doi.org/10.1080/09542299.2015.1023086

Acknowledgements

This study was derived from the Master of Science thesis of “Optimization of Pre-treatment Factors with Organic Acids under Pressure-Dependent Conditions of Sugar Beet Pulp” from Niğde Ömer Halisdemir University. This work was not supported by any projects.

Author information

Authors and Affiliations

Contributions

CG, NAÖ, and EUD contributed to the study conception and design. Material preparation and analysis were performed by NAÖ and CG. CG wrote the manuscript with support from EUD and NAÖ, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gönen, Ç., Akter Önal, N. & Deveci, E.Ü. Optimization of sugar beet pulp pre-treatment with weak and strong acid under pressure and non-pressure conditions via RSM. Biomass Conv. Bioref. 13, 9213–9226 (2023). https://doi.org/10.1007/s13399-021-02182-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02182-6