Abstract

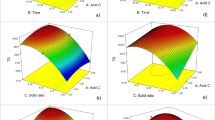

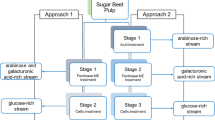

Sulfurous acid was used for pretreatment of sugar beet pulp (SBP) in order to achieve high efficiency of both extraction of carbohydrates and subsequent enzymatic hydrolysis of the remaining solids. The main advantage of sulfurous acid usage as pretreatment agent is the possibility of its regeneration. Application of sulfurous acid as hydrolyzing agent in relatively low concentrations (0.6–1.0 %) during a short period of time (10–20 min) and low solid to liquid ratio (1:3, 1:6) allowed effective extraction of carbohydrates from SBP and provided positive effect on subsequent enzymatic hydrolysis. The highest obtained concentration of reducing substances (RS) in hydrolysates was 8.5 %; up to 33.6 % of all carbohydrates present in SBP could be extracted. The major obtained monosaccharides were arabinose and glucose (9.4 and 7.3 g/l, respectively). Pretreatment of SBP with sulfurous acid increased 4.6 times the yield of glucose during subsequent enzymatic hydrolysis of remaining solids with cellulase cocktail, as compared to the untreated SBP. Total yield of glucose during SBP pretreatment and subsequent enzymatic hydrolysis amounted to 89.4 % of the theoretical yield. The approach can be applied directly to the wet SBP. Hydrolysis of sugar beet pulp with sulfurous acid is recommended for obtaining of individual monosaccharides, as well as nutritional media.

Similar content being viewed by others

References

Zheng, Y., Yu, C., Cheng, Y. S., Lee, C., Simmons, C. W., Dooley, T. M., Zhang, R., Jenkins, B. M., & Vander-Gheynst, J. S. (2012). Integrating sugar beet pulp storage, hydrolysis and fermentation for fuel ethanol production. Applied Energy, 93, 168–175.

Hotchkiss, A. T., Fishman, M., & Liu, L. S. (2010). The role of sugar beet pulp polysaccharides in the sustainability of the sugar beet industry. ACS Symposium Series, 1058, 283–290.

Kühnel, S., Schols, H., & Gruppen, H. (2011). Aiming for the complete utilization of sugar-beet pulp: examination of the effects of mild acid and hydrothermal pretreatment followed by enzymatic digestion. Biotechnology for Biofuels, 4, 1–14.

Micard, V., Renard, C., & Thibault, J.-F. (1996). Enzymatic saccharification of sugar-beet. Enzyme and Microbial Technology, 19, 162–170.

Foster, B. L., Dale, B. E., & Doran-Peterson, J. B. (2001). Enzymatic hydrolysis of ammonia-treated sugar beet pulp. Applied Biochemistry and Biotechnology, 91–93, 269–282.

Olsman, A. F. S., Huurdeman, C. M., Jansen, W. L., Haaksma, J., van Oldruitenborgh-Oosterbaan, M. M. S., & Beynen, A. C. (2004). Macronutrient digestibility, nitrogen balance, plasma indicators of protein metabolism and mineral absorption in horse fed a ration rich in sugar beet pulp. Journal of Animal Physiology and Animal Nutrition (Berlin), 88(9–10), 321–331.

Leijdekkers, A. G., Bink, J. P., Geutjes, S., Schols, H. A., & Gruppen, H. (2013). Enzymatic saccharification of sugar beet pulp for the production of galacturonic acid and arabinose; a study on the impact of the formation of recalcitrant oligosaccharides. Bioresource Technology, 128, 518–525.

Doran, J., Cripe, J., Sutton, M., & Foster, B. (2000). Fermentations of pectin-rich biomass with recombinant bacteria to produce fuel ethanol. Applied Biochemistry and Biotechnology, 84–86, 141–152.

Donkoh, E., Degenstein, J., Tucker, M., & Ji, Y. (2012). Optimization of enzymatic hydrolysis of dilute acid pretreated sugar beet pulp using response surface design. Journal of Sugar Beet Research, 49(1–2), 26–37.

Wooley, R., Ruth, M., Glassner, D., & Sheehan, J. (1999). Process design and costing of bioethanol technology: a tool for determining the status and direction of research and development. Biotechnology Progress, 15, 794–803.

Scheper, T., Hitzmann, B., Stark, E., Ulber, R., Faurie, R., Sosnitza, P., & Reardon, K. F. (1999). Bioanalytics: detailed insight into bioprocesses. Analytica Chimica Acta, 400, 121–134.

Himmel, M. E., Ding, S.-Y., Johnson, D. K., Adney, W. S., Nimlos, M. R., Brady, J. W., & Foust, T. D. (2007). Biomass recalcitrance: engineering plants and enzymes for biofuel production. Science, 315, 804–807.

Werpy, T., & Petersen, G. R. (2004). Top value added chemicals from biomass. Volume I: results of screening for potential candidates from sugars and synthesis gas. Oak Ridge: U.S. Department of Energy.

Alvira, P., Tomas-Pejo, E., Ballesteros, M., & Negro, M. J. (2010). Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresource Technology, 101(13), 4851–4861.

Palmqvist, E., & Hahn-Hägerdal, B. (2000). Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresource Technology, 74, 17–24.

Sun, Y., & Cheng, J. (2002). Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresource Technology, 83(1), 1–11.

El-Tayeb, T. S., Abdelhafez, A. A., Ali, S. H., & Ramadan, E. M. (2012). Effect of acid hydrolysis and fungal biotreatment on agro-industrial wastes for obtainment of free sugars for bioethanol production. Brazilian Journal of Microbiology, 4, 1523–1535.

Nurtdinov, R. M., Mukhachov, S. G., Valeeva, R. T., & Emelyanov, V. M. (2011). High temperature hydrolysis of plant raw materials. Herald of Kazan National Research Technological University, 10, 204–208.

Fry, S. C. (1988). The growing plant cell wall: chemical and metabolic analysis (p. 121). New York: John Wiley & Sons.

Van Der Haar. (1920). Monosacchuride und aldehydesauren (p. 122). Berlin: Gebrr. Borntraeger.

Hall, J., Hazlewood, G. P., & Barker, P. J. (1988). Conserved reiterated domains in Clostridium thermocellum endoglucanases are not essential for catalytic activity. Gene, 69, 29–38.

Korol’kov, I. I. (1978). Percolation hydrolysis of vegetable raw materials. Moscow: Forest Industry. 263 pp.

Guillon, F., Thibault, J. F., Rombouts, F. M., Voragen, A. G. J., & Pilnik, W. (1989). Enzymic hydrolysis of the “hairy” fragments of sugar-beet pectins. Carbohydrate Research, 190, 97–108.

Oosterveld, A., Beldman, G., Schols, H. A., & Voragen, A. G. J. (2000). Characterization of arabinose and ferulic acid rich pectic polysaccharides and hemicelluloses from sugar beet pulp. Carbohydrate Research, 328, 185–197.

Marry, M., McCann, M. C., Kolpak, F., White, A. R., Stacey, N. J., & Roberts, K. (2000). Extraction of pectic polysaccharides from sugar-beet cell walls. Journal of the Science of Food and Agriculture, 80, 17–28.

Colquhoun, I., Ralet, M.-C., Thibault, J.-F., Faulds, C. B., & Williamson, G. (1994). Structure identification of feruloylated oligosaccharides from sugar-beet pulp by NMR spectroscopy. Carbohydrate Research, 263, 243–256.

Zeng, M., Mosier, N. S., & Huang, C. P. (2007). Microscopic examination of changes of plant cell structure in corn stover due to hot water pretreatment and enzymatic hydrolysis. Biotechnology and Bioengineering, 7, 265–278.

Dadi, A. P., Schall, C. A., & Varanasi, S. (2007). Enzymatic hydrolysis of cellulose materials treated with ionic liquid. Chinese Science Bulletin, 51, 2432–2436.

Ruiz, E., Cara, C., Manzanares, P., Ballesteros, M., & Castro, E. (2008). Evaluation of steam explosion pretreatment for enzymatic hydrolysis of sunflower stalks. Enzyme and Microbial Technology, 2, 160–166.

Cellulosic ethanol Novozymes Cellic® CTec2 and HTec2—enzymes for hydrolysis of lignocellulosic Application sheet. Available from: http://bioenergy.novozymes.com/en/cellulosic-ethanol/CellicCTec3/Documents/AS_2010-01668-03.pdf

Acknowledgments

We would like to express our gratitude to Novozymes company for kindly provided enzyme preparation CellicCTec2 for this investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kharina, M., Emelyanov, V., Mokshina, N. et al. Pretreatment of Sugar Beet Pulp with Dilute Sulfurous Acid is Effective for Multipurpose Usage of Carbohydrates. Appl Biochem Biotechnol 179, 307–320 (2016). https://doi.org/10.1007/s12010-016-1995-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-1995-x