Abstract

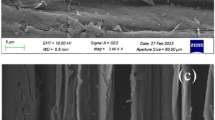

To obtain high yields of products through bioconversion processes, biomass must be pretreated to change its recalcitrant structures. The key goal of this analysis is to compare the findings in terms of total reducing sugar yield after organic solvents and hot water pretreatment on finger millet straw (FMS) using laboratory-scale equipment. Accordingly, the effect of two separate pretreatments, i.e., liquid hot water, and organic solvent (ethanol) at autoclave, and furnace temperatures, was investigated in this study to increase the enzymatic conversion of FMS under optimal conditions. The biomass recovery was found highest under the liquid hot water (autoclave; 94.77 ± 0.017%) pretreatment conditions. In addition, the cellulose content improved significantly with pretreatment, increasing from 41.7 ± 0.74 to 55.33 ± 0.89%, while the hemicellulose and lignin contents significantly decreased. The untreated sample having a lignin amount of around 6.42 ± 0.21% after different pretreatment methods dropped significantly (p = 0.00737**) and was found to have a 39.8 ± 1.84% delignification rate based on the ethanol autoclave method. The findings of the study revealed that the FMS is severely affected by liquid hot water and organic solvent pretreatment in the autoclave than the furnace. After the pretreatment procedure, the maximum amount of crystalline cellulose in biomass was transformed to the amorphous state, as shown by the Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and X-ray diffraction (XRD). The pretreated cellulase blend enzyme sample was most active on the biomass treated with 1:20% (w/v) liquid hot water combined with autoclave heating at 121 °C, with 15 psi for 20 min, resulting in highest total reducing sugars; thus, results showed that the pretreated sample (0.75 g) contains 60.94 mg/g of fermentative sugars based on a 15% (w/v) ratio which claimed to be the fact that this is a better result than any other research by using FMS.

Graphical abstract

Similar content being viewed by others

Data availability

Data can be available from the corresponding author on reasonable request.

Change history

13 May 2023

A Correction to this paper has been published: https://doi.org/10.1007/s13399-023-04315-5

Abbreviations

- ADF:

-

Acid detergent fiber

- ADL:

-

Acid detergent lignin

- CBP:

-

Consolidated bioprocessing

- CrI:

-

Crystallinity index

- DNS:

-

3,5-Dinitrosalicylic acid

- DP:

-

Degree of polymerization

- FMS:

-

Finger millet straw

- FTIR:

-

Fourier transform infrared spectroscopy

- Gtoe:

-

Gigatonne of oil equivalent

- HMF:

-

Hydroxymethylfurfural

- HVO:

-

Hydrotreated vegetable oil

- LC:

-

Lignocellulose

- LHW:

-

Liquid hot water

- MPa:

-

Megapascal

- Mtoe:

-

Millions of tonnes of oil equivalent

- NDF:

-

Neutral detergent fiber

- OS:

-

Organic solvent

- PSSCF:

-

Pre-hydrolysis, simultaneous saccharification, and co-fermentation

- RFA:

-

Renewable Fuels Association

- RPM:

-

Revolution per minute

- RS:

-

Rice straw

- SEM:

-

Scanning electron microscopy

- SGB:

-

Second-generation bioethanol

- SSCF:

-

Simultaneous saccharification and co-fermentation

- SVOCs:

-

Semi-volatile organic compounds

- TRS:

-

Total reducing sugar

- VOC:

-

Volatile organic compound

- XRD:

-

X-ray diffraction

References

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315(5813):804–807. https://doi.org/10.1126/science.1137016

Lorne D, Bouter A (2019) Biofuels dashboard 2019 IFPEN. ifp energies nouvelles https://www.ifpenergiesnouvelles.com/article/biofuels-dashboard-2019 (accessed Mar. 27, 2020).

Bioenergy International (2020) https://bioenergyinternational.com/markets-finance/us-tops-as-number-one-ethanol-producer-consumer-and-exporter (accessed Apr. 03, 2020).

Brethauer S, Wyman CE (2010) Review: Continuous hydrolysis and fermentation for cellulosic ethanol production. Bioresour Technol 101(13):4862–4874. https://doi.org/10.1016/j.biortech.2009.11.009

Lamichhane G, Khadka S, Adhikari S, Koirala N, Poudyal DP (2020) Biofuel production from waste cooking oils and its physicochemical properties in comparison to petrodiesel. Nepal J Biotechnol 8(3):87–94. https://doi.org/10.3126/njb.v8i3.33661

Ho DP, Ngo HH, Guo W (2014) A mini review on renewable sources for biofuel. Biores Technol 169:742–749. https://doi.org/10.1016/j.biortech.2014.07.022

Jain N, Bhatia A, Pathak H (2014) Emission of air pollutants from crop residue burning in India. Aerosol and Air Quality Research 14(1):422–430. https://doi.org/10.4209/aaqr.2013.01.0031

Mittal SK, Singh N, Agarwal R, Awasthi A, Gupta PK (2009) Ambient air quality during wheat and rice crop stubble burning episodes in Patiala. Atmos Environ 43(2):238–244

Zhang H, Hu D, Chen J, Ye X, Wang SX, Hao JM, Wang L, Zhang R, An Z (2011) Particle size distribution and polycyclic aromatic hydrocarbons emissions from agricultural crop residue burning. Environ Sci Technol 45(13):5477–5482. https://doi.org/10.1021/es1037904

Luitel DR, Siwakoti M, Joshi MD, Rangaswami M, Jha PK (2020) Potential suitable habitat of Eleusine coracana (L) Gaertn (finger millet) under the climate change scenarios in Nepal. BMC Ecol 20(1):19. https://doi.org/10.1186/s12898-020-00287-6

Banu JS (2019) Saccharification and fermentation of finger millet straw using recombinant hydrolytic enzymes and fermentative microbe for bioethanol production, Thesis. Accessed: May 09, 2021. [Online]. Available: http://gyan.iitg.ac.in:8080/xmlui/handle/123456789/1615

Cherubini F, Stro̷mman AH, (2010) Production of biofuels and biochemicals from lignocellulosic biomass: estimation of maximum theoretical yields and efficiencies using matrix algebra. Energy Fuels 24(4):2657–2666. https://doi.org/10.1021/ef901379s

Jamaldheen SB, Thakur A, Moholkar VS, Goyal A (2019) Enzymatic hydrolysis of hemicellulose from pretreated finger millet (Eleusine coracana) straw by recombinant endo-1,4-β-xylanase and exo-1,4-β-xylosidase. Int J Biol Macromol 135:1098–1106. https://doi.org/10.1016/j.ijbiomac.2019.06.010

Yemets AI, Blume RY, Rakhmetov DB, Blume YB (2020) Finger millet as a sustainable feedstock for bioethanol production. Open Agric J 14(1):257–272. https://doi.org/10.2174/1874331502014010257

Mosier N (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96(6):673–686. https://doi.org/10.1016/j.biortech.2004.06.025

Awoyale AA, Lokhat D (2021) Experimental determination of the effects of pretreatment on selected Nigerian lignocellulosic biomass in bioethanol production. Sci Rep 11(1):557. https://doi.org/10.1038/s41598-020-78105-8

Kim Y, Hendrickson R, Mosier NS, Ladisch MR (2009) Liquid hot water pretreatment of cellulosic biomass. Biofuels, Humana Press 581:93–102. https://doi.org/10.1007/978-1-60761-214-8_7

Imman S, Laosiripojana N, Champreda V (2018) Effects of liquid hot water pretreatment on enzymatic hydrolysis and physicochemical changes of corncobs. Appl Biochem Biotechnol 184(2):432–443. https://doi.org/10.1007/s12010-017-2541-1

da Silva ARG, Errico M, Rong BG (2018) Evaluation of organosolv pretreatment for bioethanol production from lignocellulosic biomass: solvent recycle and process integration. Biomass Convers Biorefinery 8(2):397–411. https://doi.org/10.1007/s13399-017-0292-4

Baruah J, Bikash K, Sharma R, Kumar S, Deka RC, Baruah DC, Kalita E (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6. doi: https://doi.org/10.3389/fenrg.2018.00141.https://doi.org/10.3389/fenrg.2018.00141

Maitan-Alfenas GP, Visser EM, Guimarães VM (2015) Enzymatic hydrolysis of lignocellulosic biomass: converting food waste in valuable products. Curr Opin Food Sci 1:44–49. https://doi.org/10.1016/j.cofs.2014.10.001

Binod P, Janu KU, Sindhu R, Pandey A (2011) Hydrolysis of lignocellulosic biomass for bioethanol production. Biofuels, Elsevier 229–250. doi: 10.1016/B978-0-12-385099-7.00010-3.https://doi.org/10.1016/B978-0-12-385099-7.00010-3

Lamichhane G, Acharya A, Poudel DK et al (2021) Recent advances in bioethanol production from lignocellulosic biomass. Int J Green Energy 18(7):731–744. https://doi.org/10.1080/15435075.2021.1880910

Ayodele BV, Alsaffar MA, Mustapa SI (2020) An overview of integration opportunities for sustainable bioethanol production from first- and second-generation sugar-based feedstocks. J Clean Prod 245:118857. https://doi.org/10.1016/j.jclepro.2019.118857

Zheng Q (2018) Pretreatment of wheat straw leads to structural changes and improved enzymatic hydrolysis. Sci Rep 9.

Ramadoss G, Muthukumar K (2015) Influence of dual salt on the pretreatment of sugarcane bagasse with hydrogen peroxide for bioethanol production. Chem Eng J 260:178–187. https://doi.org/10.1016/j.cej.2014.08.006

Goel A, Wati L (2016) Ethanol production from rice (Oryza sativa) straw by simultaneous saccharification and cofermentation. Indian J Exp Biol 54(8):525–9

Zhang HD, Wu SB (2014) Impact of liquid hot water pretreatment on the structural changes of sugarcane bagasse biomass for sugar production. Appl Mech Mater 472:774–779. https://doi.org/10.4028/www.scientific.net/AMM.472.774

Amiri H, Karimi K, Zilouei H (2014) Organosolv pretreatment of rice straw for efficient acetone, butanol, and ethanol production. Bioresour Technol 152:450–456. https://doi.org/10.1016/j.biortech.2013.11.038

Zhang K, Pei Z, Wang D (2016) Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: a review. Bioresour Technol 199:21–33. https://doi.org/10.1016/j.biortech.2015.08.102

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3(1):10. https://doi.org/10.1186/1754-6834-3-10

Baksi S, Ball AK, Sarkar U, Banerjee D, Wentzel A, Preisig HA, Kuniyal JC, Birgen C, Saha S, Wittgens B, Markussen S (2019) Efficacy of a novel sequential enzymatic hydrolysis of lignocellulosic biomass and inhibition characteristics of monosugars. Int J Biol Macromol 129:634–644. https://doi.org/10.1016/j.ijbiomac.2019.01.188

Dahnum D, Tasum SO, Triwahyuni E, Nurdin M, Abimanyu H (2015) Comparison of SHF and SSF processes using enzyme and dry yeast for optimization of bioethanol production from empty fruit bunch. Energy Procedia 68:107–116. https://doi.org/10.1016/j.egypro.2015.03.238

Gomori G (1995) Preparation of buffers for use in enzyme studies. Methods Enzymol 1:138–146. https://doi.org/10.1016/0076-6879(55)01020-3

Manzanares P, Negro MJ, Oliva JM, Saéz F, Ballesteros I, Ballesteros M, Cara C, Castro E, Ruiz E (2011) Different process configurations for bioethanol production from pretreated olive pruning biomass. J Chem Technol Biotechnol 86(6):881–887. https://doi.org/10.1002/jctb.2604

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 3.

Singh J, Sharma A, Sharma P et al (2020) Valorization of jute (Corchorus sp.) biomass for bioethanol production. Biomass Convers Biorefinery. doi: https://doi.org/10.1007/s13399-020-00937-1.

Madibela OR, Modiakgotla E (2004) Chemical composition and in vitro dry matter digestibility of indigenous finger millet (Eleusine coracana) in Botswana. Livest Res Rural Dev 16(4):7

Ambye-Jensen M, Balzarotti R, Thomsen ST, Fonseca C, Kádár Z (2018) Combined ensiling and hydrothermal processing as efficient pretreatment of sugarcane bagasse for 2G bioethanol production. Biotechnol Biofuels 11(1):336. https://doi.org/10.1186/s13068-018-1338-y

Nasirpour N, Mousavi SM, Shojaosadati SA (2014) A novel surfactant-assisted ionic liquid pretreatment of sugarcane bagasse for enhanced enzymatic hydrolysis. Bioresour Technol 169:33–37. https://doi.org/10.1016/j.biortech.2014.06.023

Banerjee R (2018) Pilot scale production of 2G ethanol utilizing rice straw: an integrated bio-refinery approach. J Fundam Renew. Energy Appl. doi: https://doi.org/10.4172/2090-4541-C4-058.

Germec M, Turhan I (2018) Ethanol production from acid-pretreated and detoxified rice straw as sole renewable resource. Biomass Convers Biorefinery 8(3):607–619. https://doi.org/10.1007/s13399-018-0310-1

Park J et al (2010) A novel lime pretreatment for subsequent bioethanol production from rice straw – calcium capturing by carbonation (CaCCO) process. Bioresour Technol 101(17):6805–6811. https://doi.org/10.1016/j.biortech.2010.03.098

Erdei B, Barta Z, Sipos B, Réczey K, Galbe M, Zacchi G (2010) Ethanol production from mixtures of wheat straw and wheat meal. Biotechnol Biofuels 3(1):16. https://doi.org/10.1186/1754-6834-3-16

Nielsen F, Zacchi G, Galbe M, Wallberg O (2017) Sequential targeting of xylose and glucose conversion in fed-batch simultaneous saccharification and co-fermentation of steam-pretreated wheat straw for improved xylose conversion to ethanol. BioEnergy Res 10(3):800–810. https://doi.org/10.1007/s12155-017-9841-8

Ruiz HA, Silva DP, Ruzene DS, Lima LF, Vicente AA, Teixeira JA (2012) Bioethanol production from hydrothermal pretreated wheat straw by a flocculating Saccharomyces cerevisiae strain – effect of process conditions. Fuel 95:528–536. https://doi.org/10.1016/j.fuel.2011.10.060

Zhang N et al (2020) Effects of liquid hot water combined with 1, 4-butanediol on chemical composition and structure of moso bamboo. Appl Biochem Biotechnol 190(4):1177–1186. https://doi.org/10.1007/s12010-019-03173-0

Bals B, Rogers C, Jin M, Balan V, Dale B (2010) Evaluation of ammonia fibre expansion (AFEX) pretreatment for enzymatic hydrolysis of switchgrass harvested in different seasons and locations. Biotechnol Biofuels 3(1):1. https://doi.org/10.1186/1754-6834-3-1

Bokinsky G et al (2011) Synthesis of three advanced biofuels from ionic liquid-pretreated switchgrass using engineered Escherichia coli. Proc Natl Acad Sci 108(50):19949–19954. https://doi.org/10.1073/pnas.1106958108

Zhang J, Zhou H, Liu D, Zhao X (2020) Pretreatment of lignocellulosic biomass for efficient enzymatic saccharification of cellulose. Lignocellulosic Biomass to Liquid Biofuels Elsevier 17–65. doi: https://doi.org/10.1016/B978-0-12-815936-1.00002-2

Zhao X, Cheng K, Liu D (2009) Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl Microbiol Biotechnol 82(5):815–827. https://doi.org/10.1007/s00253-009-1883-1

Bhardwaj N, Kumar B, Verma P (2020) Microwave-assisted pretreatment using alkali metal salt in combination with orthophosphoric acid for generation of enhanced sugar and bioethanol. Biomass Convers. Biorefinery. doi: https://doi.org/10.1007/s13399-020-00640-1.

Indira D, Jayabalan R (2020) Saccharification of lignocellulosic biomass using seawater and halotolerant cellulase with potential application in second-generation bioethanol production. Biomass Convers Biorefinery 10(3):639–650. https://doi.org/10.1007/s13399-019-00468-4

Awedem WF, Chaturvedi T, Boda M et al (2019) Bioethanol potential of raw and hydrothermally pretreated banana bulbs biomass in simultaneous saccharification and fermentation process with Saccharomyces cerevisiae. Biomass Convers Biorefinery 9(3):553–563. https://doi.org/10.1007/s13399-018-00367-0

Poornejad N, Karimi K, Behzad T (2014) Ionic liquid pretreatment of rice straw to enhance saccharification and bioethanol production. J Biomass Biofuel 1. doi: https://doi.org/10.11159/jbb.2014.002.https://doi.org/10.11159/jbb.2014.002

Sindhu R, Binod P, Janu KU, Sukumaran RK, Pandey A (2012) Organosolvent pretreatment and enzymatic hydrolysis of rice straw for the production of bioethanol. World J Microbiol Biotechnol 28(2):473–483. https://doi.org/10.1007/s11274-011-0838-8

Amro A, Abhary M (2019) Removal of lead and cadmium ions from water using Cladophora biomass. Pol J Environ Stud 28(5):3589–3596. https://doi.org/10.15244/pjoes/94622

Kumar S, Gandhi P, Yadav M, Paritosh K, Pareek N, Vivekanand V (2019) Weak alkaline treatment of wheat and pearl millet straw for enhanced biogas production and its economic analysis. Renew Energy 139:753–764. https://doi.org/10.1016/j.renene.2019.02.133

Chandra RR, Banerjee R (2016) Enzyme mediated biomass pretreatment and hydrolysis: a biotechnological venture towards bioethanol production. RSC Ad 6(66):61301–61311. https://doi.org/10.1039/C6RA09541K

Alam A et al (2019) A finalized determinant for complete lignocellulose enzymatic saccharification potential to maximize bioethanol production in bioenergy Miscanthus. Biotechnol Biofuels 12(1):99. https://doi.org/10.1186/s13068-019-1437-4

Karimi K, Taherzadeh MJ (2016) A critical review of analytical methods in pretreatment of lignocelluloses: composition, imaging, and crystallinity. Bioresour Technol 200:1008–1018. https://doi.org/10.1016/j.biortech.2015.11.022

Acknowledgements

The authors would like to acknowledge the Central Salt and Marine Chemical Research Institute, Bhavnagar, Gujarat, India, and the Sophisticated Test and Instrumentation Centre (STIC), Cochin University of Science and Technology, Cochin, 682022, Kerala, India, for the SEM and XRD analysis, respectively. In addition, the authors would like to give their profound gratitude to Mr. Karan Khadayat for his suggestions. The authors also acknowledge Mr. Sagar Aryal for providing the figures through biorender.com.

Author information

Authors and Affiliations

Contributions

GL performed the lab experiment and prepared the initial draft of the manuscript. SK and AA edited as well as revised the manuscript in collaboration with GL. GL, SK, and AA performed the data analysis, and NP supervised this work.

Corresponding author

Ethics declarations

Declarations

Not applicable.

Consent for publication

The authors declare that there is no conflict of interest regarding the publication of this paper.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: A typographical error in the Abstract was fixed.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lamichhane, G., Khadka, S., Acharya, A. et al. Pretreatment of finger millet straw (Eleusine coracana) for enzymatic hydrolysis towards bioethanol production. Biomass Conv. Bioref. 13, 6105–6119 (2023). https://doi.org/10.1007/s13399-021-01633-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01633-4