Abstract

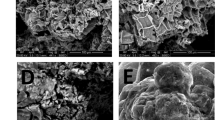

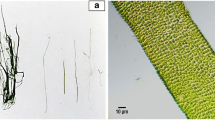

Global water scarcity at an alarming stage has triggered the interest of many environmentalists and global researchers. Use of freshwater in biomass-based industries would result in depletion of a precious natural resource, which is not sustainable in the long term. Thus, water management technologies are critical to the successful operation of an ethanol plant. Utilization of seawater-based systems and halotolerant enzymes can be a breakthrough in this context. The present study involves marine bacterial strains Bacillus oceanisediminis, Brevibacterium halotolerans, and Psychrobacter celer capable of producing halotolerant cellulases, isolated from Gopalpur, Odisha. The crude enzyme extracts and direct bacterial cultures were independently utilized for saccharification of pretreated rice straw, and the treated rice straw was characterized for the production of reducing sugars using high-performance liquid chromatography (HPLC). The possible bond breakage and formation during saccharification of cellulose was assessed using attenuated total reflectance with Fourier transform infrared (ATR-FTIR) spectroscopy. The relative fraction and size of crystallites in cellulose was evaluated by X-ray diffraction (XRD) study. The biomass saccharified using the crude cellulase from B. oceanisedimins was utilized for the production of bioethanol in freshwater and seawater-based media using Saccharomyces cerevisiae NCIM 3570 and Candida shehatae NCIM 3500. The maximum fermentation efficiency (45.74%) was recorded for saccharified rice straw in freshwater using a consortium of immobilized yeasts. The highest fermentation efficiency (36.69%) was recorded in the seawater system by immobilized S. cerevisiae.

Similar content being viewed by others

References

WWAP (United Nations World Water Assessment Programme) (2014) The United Nations world water development report 2014: water and energy. UNESCO, Paris

Indira D, Das B, Balasubramanian P, Jayabalan R. (2018) Sea water as a reaction medium for bioethanol production. In Patra JK, Das G, Shin HS (Eds.), Microbial Biotechnology: Application in Food and Pharmacology. (pp. 171-192). Singapore: Springer

Keeney D, Muller M (2006) Water use by ethanol plants: potential challenges. Institute for Agriculture and Trade Policy, Minneapolis, MN

Ren H, Zong MH, Wu H, Li N (2016) Utilization of seawater for the biorefinery of lignocellulosic biomass: ionic liquid pretreatment, enzymatic hydrolysis, and microbial lipid production. ACS Sustain Chem Eng 4(10):5659–5666

Lima RN, Porto ALM (2016) Recent advances in marine enzymes for biotechnological processes. In Advances in food and nutrition research (Vol. 78, pp. 153-192). Academic Press

Oren A (2010) Industrial and environmental applications of halophilic microorganisms. Environ Technol 3:825–834

Hutcheon GW, Vasisht N, Bolhuis A (2005) Characterisation of a highly stable a-amylase from the halophilic archaeon Haloarcula hispanica. Extremophiles 9:487–495

Oren A (2008) Microbial life at high salt concentrations: phylogenetic and metabolic diversity. Saline Syst 4(1):2

Trivedi N, Gupta V, Kumar M, Kumari P, Reddy CRK, Jha B (2010) An alkali-halotolerant cellulase from Bacillus flexus isolated from green seaweed Ulva lactuca. Carbohydr Polym 83(2):891–897

Grande PM, De Maria PD (2012) Enzymatic hydrolysis of microcrystalline cellulose in concentrated seawater. Bioresour Technol 104:799–802

Singhania RR, Sukumaran RK, Patel AK, Larroche C, Pandey A (2010) Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzym Microb Technol 46(7):541–549

Yang H, Pfister S, Bhaduri A (2013) Accounting for a scarce resource: virtual water and water footprint in the global water system. Curr Opin Environ Sustain 5(6):599–606

Gerbens-Leenes W, Hoekstra AY, van der Meer TH (2009) The water footprint of bioenergy. Proc Natl Acad Sci 106(25):10219–10223

Gerbens-Leenes W, Hoekstra AY (2012) The water footprint of sweeteners and bio-ethanol. Environ Int 40:202–211

Zaky AS, Greetham D, Louis EJ, Tucker G, Du C (2016) A new isolation and evaluation method for marine-derived yeast spp. with potential applications in industrial biotechnology. J Microbiol Biotechnol 26(11):1891–1907

Greetham D, Zaky A, Makanjuola O, Du C (2018) A brief review on bioethanol production using marine biomass, marine microorganism and seawater. Curr Opin Green Sustain Chem 14: 53-59

Klement T, Milker S, Jäger G, Grande PM, de María PD, Büchs J (2012) Biomass pretreatment affects Ustilago maydis in producing itaconic acid. Microb Cell Fact 11(1): 43

Vom Stein T, Grande P, Sibilla F, Commandeur U, Fischer R, Leitner W, de María PD (2010) Salt-assisted organic-acid-catalyzed depolymerization of cellulose. Green Chem 12(10):1844–1849

Senthilraja P, Kathiresan K, Saravanakumar K (2011) Comparative analysis of bioethanol production by different strains of immobilized marine yeast. J Yeast Fungal Res 2(8):113–116

Urano N, Yamazaki M, Ueno R (2001) Distribution of halotolerant and/or fermentative yeasts in aquatic environments. J Tokyo Univ Fish 87:23–30

Gonçalves FA, Santos ESD, de Macedo GR (2015) Alcoholic fermentation of Saccharomyces cerevisiae, Pichia stipitis and Zymomonas mobilis in the presence of inhibitory compounds and seawater. J Basic Microbiol 55(6):695–708

Templeton D, Ehrman T (1995) Chemical analysis and testing task: LAP-003 (Determination of acid-insoluble lignin in Biomass) National Renewable Energy Laboratory. Golden, USA

Tailliez P, Girard H, Millet J, Beguin P (1989) Enhanced cellulose fermentation by an asporogenous and ethanol-tolerant mutant of Clostridium thermocellum. Appl Environ Microbiol 55(1):207–211

Indira D, Sharmila D, Balasubramanian P, Thirugnanam A, Jayabalan R (2016) Utilization of sea water based media for the production and characterization of cellulase by Fusarium subglutinans MTCC 11891. Biocatal Agric Biotechnol 7:187–192

Beecher JF, Hunt CG, Zhu JY (2009) Tools for the characterization of biomass at the nanometer scale, The nanoscience and technology of renewable biomaterials, 1st edn. Blackwell Publishing, Singapore, pp 61–80

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3(1):10

Indira D, Jijnasa B, Arati N, Moumita S, Ajay D, Eldin J, Jayabalan R (2015) Comparative studies of ethanol production and cell viability: free cells versus immobilized cells. Res J Pharm Biol Chem Sci 6(2):1708–1714

Berłowska J, Pielech-Przybylska K, Balcerek M, Dziekońska-Kubczak U, Patelski P, Dziugan P, Kręgiel D (2016) Simultaneous saccharification and fermentation of sugar beet pulp for efficient bioethanol production. BioMed Res Intl 2016, 3154929, 10 pages.

Chandel AK, Chan EC, Rudravaram R, Narasu ML, Rao LV, Ravindra P (2007) Economics and environmental impact of bioethanol production technologies: an appraisal. Biotechnol Mol Biol 2:14–32

Sukumaran RK, Singhania RR, Mathew GM, Pandey A (2009) Cellulase production using biomass feed stock and its application in lignocellulose saccharification for bio-ethanol production. Renew Energy 34(2):421–424

Ko JK, Bak JS, Jung MW, Lee HJ, Choi IG, Kim TH, Kim KH (2009) Ethanol production from rice straw using optimized aqueous-ammonia soaking pretreatment and simultaneous saccharification and fermentation processes. Bioresour Technol 100(19):4374–4380

Zaky AS, Pensupa N, Andrade-Eiroa Á, Tucker GA, Du C (2017) A new HPLC method for simultaneously measuring chloride, sugars, organic acids and alcohols in food samples. J Food Compos Anal 56:25–33

Michell AJ, Schimleck LR (1996) NIR spectroscopy of woods from Eucalyptus globules. Appita J 49(1):23–26

Baillères H, Davrieux F, Ham-Pichavant F (2002) Near infrared analysis as a tool for rapid screening of some major wood characteristics in a eucalyptus breeding program. Ann For Sci 59(5–6):479–490

Adina CHIŞ, Florinela FETEA, Abdelmoumen TAOUTAOU, Carmen S (2010) Application of FTIR spectroscopy for a rapid determination of some hydrolytic enzymes activity on sea buckthorn substrate. Rom Biotechnol Lett 15(6):5738–5744

Xu F, Yu J, Tesso T, Dowell F, Wang D (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809

Schwanninger M, Rodrigues J, Pereira H, Hinterstoisser B (2004) Effects of short time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectrosc 36:23–40

Kubo S, Kadla JF (2005) Hydrogen bonding in lignin: a Fourier transform infrared model compound study. Biomacromolecules 6:2815–2821

Sills DL, Gossett JM (2012) Using FTIR to predict saccharification from enzymatic hydrolysis of alkali pretreated biomasses. Biotechnol Bioeng 109:353–362

Binod P, Satyanagalakshmi K, Sindhu R, Janu KU, Sukumaran RK, Pandey A (2012) Short duration microwave assisted pretreatment enhances the enzymatic saccharification and fermentable sugar yield from sugarcane bagasse. Renew Energy 37(1):109–116

Karthika K, Arun AB, Rekha PD (2012) Enzymatic hydrolysis and characterization of lignocellulosic biomass exposed to electron beam irradiation. Carbohydr Polym 90(2):1038–1045

Mittal A, Katahira R, Himmel ME, Johnson DK (2011) Effects of alkaline or liquidammonia treatment on crystalline cellulose: changes in crystalline structure and effects on enzymatic digestibility. Biotechnol Biofuels 4:41

Singh J, Suhag M, Dhaka A (2015) Augmented digestion of lignocellulose by steam explosion, acid and alkaline pretreatment methods: a review. Carbohydr Polym 117:624–631

Sindhu R, Kuttiraja M, Binod P, Janu KU, Sukumaran RK, Pandey A (2011) Dilute acid pretreatment and enzymatic saccharification of sugarcane tops for bioethanol production. Bioresour Technol 102(23):10915–10921

Samuel R, Pu Y, Foston M, Ragauskas AJ (2010) Solid-state NMR characterization of switchgrass cellulose after dilute acid pretreatment. Biofuels 1(1):85–90

Zhang T, Datta S, Eichler J, Ivanova N, Axen SD (2011) Identification of a haloalkaliphilic and thermostable cellulase with improved ionic liquid tolerance. Green Chem 13:2083–2090

Cao Y, Tan HJ (2004) Structural characterization of cellulose with enzymatic treatment. J Mol Struct 705:189–193

Kshirsagar SD, Waghmare PR, Loni PC, Patil SA, Govindwar SP (2015) Dilute acid pretreatment of rice straw, structural characterization and optimization of enzymatic hydrolysis conditions by response surface methodology. RSC Adv 5(58):46525–46533

Hohmann S (2002) Osmotic stress signaling and osmoadaptation in yeasts. Microbiol Molbiol Rev 66(2):300–372

Zaky AS, Greetham D, Tucker GA, Du C (2018) The establishment of a marine focused biorefinery for bioethanol production using seawater and a novel marine yeast strain. Sci Rep 8(1):12127

Fang C, Thomsen MH, Brudecki GP, Cybulska I, Frankaer CG, Oyanedel JRB, Schmidt JE (2015) Seawater as an alternative to fresh water in the pretreatment of date palm residues for bioethanol production in coastal and/or arid areas. ChemSusChem 8(22):3823–3831

Lau MW, Dale BE (2009) Cellulosic ethanol production from AFEX-treated corn stover using Saccharomyces cerevisiae 424A (LNH-ST). Proc Nat Acad Sci 106(5):1368–1373

Fu N, Peiris P (2008) Co-fermentation of a mixture of glucose and xylose to ethanol by Zymomonas mobilis and Pachysolen tannophilus. World J Microbiol Biotechnol 24:1091–1097

Qian M, Tian S, Li X, Zhang J, Pan Y, Yang X (2006) Ethanol production from dilute acid softwood hydrolysate by co-culture. Appl Biochem Biotechnol 134:273–283

Lebeau T, Jouenne T, Junter GA (1997) Simultaneous fermentation of glucose and xylose by pure and mixed cultures of Saccharomyces cerevisiae and Candida shehatae immobilized in a two-chambered bioreactor. Enzym Microb Technol 21:265–272

Grootjen DRJ, Jansen ML, van der Lans RGJM, Luyben KCAM (1991) Reactors in series for the complete conversion of glucose/xylose mixtures by Pichia stipitis and Saccharomyces cerevisiae. Enzym Microb Technol 13:828–833

Laplace JM, Delgenes JP, Moletta R, Navarro JM (1993) Cofermentation of glucose and xylose to ethanol by a respiratory-deficient mutant of Saccharomyces cerevisiae co-cultivated with a xylose-fermenting yeast. J Ferment Bioeng 75:207–212

De Bari I, Cuna D, Nanna F, Braccio G (2004) Ethanol production in immobilized-cell bioreactors from mixed sugar syrups and enzymatic hydrolysates of steam-exploded biomass. Appl Biochem Biotechnol 114:539–557

Hohmann S, Krantz M, Nordlander B (2007) Yeast osmoregulation. Methods Enzymol 428:29–45

Greetham D, Zaky AS, Du C (2019) Exploring the tolerance of marine yeast to inhibitory compounds for improving bioethanol production. Sustain Energy Fuels 3(6):1545–1553

Acknowledgments

The authors gratefully acknowledge the financial support and laboratory facilities from the Department of Life Science, National Institute of Technology, Rourkela, Odisha.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 5675 kb)

Rights and permissions

About this article

Cite this article

Indira, D., Jayabalan, R. Saccharification of lignocellulosic biomass using seawater and halotolerant cellulase with potential application in second-generation bioethanol production. Biomass Conv. Bioref. 10, 639–650 (2020). https://doi.org/10.1007/s13399-019-00468-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00468-4