Abstract

The potential of banana peels (BPs) as a source of fermentable sugars for ethanol production was evaluated using two yeasts: Saccharomyces cerevisiae commercial strain and Kluyveromyces marxianus thermotolerant strain isolated from Agave honey. Different process configurations: simultaneous saccharification and fermentation (SSF), as well as presaccharification and simultaneous saccharification and fermentation (PSSF) at high solid loading (up to 25% w/w), were studied. Similar ethanol production 13 g/L and 11 g/L was achieved at 10–12 h on SSF for S. cerevisiae and K. marxianus at 35 and 41 °C, respectively, with 10% (w/w) BP. The highest ethanol concentration (32.6 g/L) was reached on PSSF process (at 64 h) using commercial S. cerevisiae strain with 25% (w/v) BP, while ethanol production was inhibited in the case of K. marxianus under same assay conditions. BPs are a suitable source for second-generation ethanol production. The advantage of S. cerevisiae in the PSSF in comparison with K. marxianus was demonstrated. The present study demonstrated that BPs are the promising feedstock for ethanol production by PSSF.

Similar content being viewed by others

Abbreviations

- BP:

-

Banana peels

- SHF:

-

Separate hydrolysis and fermentation

- SSF:

-

Simultaneous saccharification and fermentation

- PSSF:

-

Presaccharification and simultaneous saccharification and fermentation

- GC:

-

Gas chromatography

- HPLC:

-

High-performance liquid chromatography

References

Oberoi HS, Vadlani PV, Saida L, Bansal S, Hughes JD (2011) Ethanol production from banana peels using statistically optimized simultaneous saccharification and fermentation process. Waste Manag 31:1576–1584. https://doi.org/10.1016/j.wasman.2011.02.007

Nagarajaiah SB, Prakash J (2011) Chemical composition and antioxidant potential of peels from three varieties of banana. Asian J Food Agric Ind 4:31–46 https://ajouronline.com/index.php/AJAFS

Clarke WP, Radnidge P, Lai TE, Jensen PD, Hardin MT (2008) Digestion of waste bananas to generate energy in Australia. Waste Manag 28:527–533. https://doi.org/10.1016/j.wasman.2007.01.012

Dhabekar A, Chandak A (2010) Utilization of banana peels and beet waste for alcohol production. Asiatic J Biotechnol Res 1:8–13 https://publons.com/journal/30391/asiatic-journal-of-biotechnology-resources

Gunaseelan VN (2004) Biochemical methane potential of fruits and vegetable solid waste feedstocks. Biomass Bioenergy 26:389–399. https://doi.org/10.1016/j.biombioe.2003.08.006

Ilori MO, Adebusoye SA, Iawal AK, Awotiwon OA (2007) Production of biogas from banana and plantain peels. Adv Environ Biol 1:33–38 https://www.scimagojr.com/journalsearch.php?q=19700177004&tip=sid

Souza O, Schulz MA, Fischer GAA, Wagner TM, Sellin N (2012) Energia alternativa de biomassa: Bioetanol a partir de casca e polpa de banana. Rev Bras Eng Agric Amb 16:915–921. https://doi.org/10.1590/S1415-43662012000800015

Velásquez-Arredondo HI, Ruiz-Colorado AA, De Oliveira Junior S (2010) Ethanol production process from banana fruit and its lignocellulosic residues: energy analysis. Energy 35:3081–3087. https://doi.org/10.1016/j.energy.2010.03.052

Benjamin C, Singh PK, Dipuraj PS (2014) Bio-ethanol production from banana peel by simultaneous saccharification and fermentation process using cocultures Aspergillus niger and Saccharomyces cerevisiae. Int J Curr Microbiol App Sci 3:84–96 https://www.ijcmas.com/

Hammond JB, Egg R, Diggins D, Coble CG (1996) Alcohol from bananas. Bioresour Technol 56:125–130 https://www.journals.elsevier.com/bioresource-technology

Itelima J, Onwuliri F, Onwuliri E, Onyimba I, Oforji S (2013) Bio-ethanol production from banana, plantain and pineapple peels by simultaneous saccharification and fermentation process. In J Environ Sci Dev 4:213–216. https://doi.org/10.7763/IJESD.2013.V4.337

Ruiz HA, Silva DP, Ruzene DS, Lima LF, Vicente AA, Teixeira JA (2012) Bioethanol production from hydrothermal pretreated wheat straw by a flocculating Saccharomyces cerevisiae strain–effect of process conditions. Fuel 95:528–536. https://doi.org/10.1016/j.fuel.2011.10.060

Oberoi HS, Sandhu SK, Vadlani PV (2012) Statistical optimization of hydrolysis process for banana peels using cellulolytic and pectinolytic enzymes. Food Bioprod Process 90:257–265. https://doi.org/10.1016/j.fbp.2011.05.002

Ruiz HA, Rodríguez-Jasso RM, Fernandes BD, Vicente AA, Teixeira JA (2013) Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept: a review. Renew Sust Energ Rev 21:35–51. https://doi.org/10.1016/j.rser.2012.11.069

Sharma N, Kalra KL, Oberoi H, Bansal S (2007) Optimization of fermentation parameters for production of ethanol from kinnow waste and banana peels by simultaneous saccharification and fermentation. Indian J Microbiol 47:310–316. https://doi.org/10.1007/s12088-007-0057-z

Ballesteros M, Oliva J, Negro M, Manzanares P, Ballesteros I (2004) Ethanol from lignocellulosic materials by a simultaneous saccharification and fermentation process (SFS) with Kluyveromyces marxianus CECT 10875. Process Biochem 39:1843–1848. https://doi.org/10.1016/j.procbio.2003.09.011

Rocha MVP, Rodrigues THS, Melo VM, Gonçalves LR, de Macedo GR (2011) Cashew apple bagasse as a source of sugars for ethanol production by Kluyveromyces marxianus CE025. J Ind Microbiol Biotechnol 38:1099–1107. https://doi.org/10.1007/s10295-010-0889-0

Rodrigues THS, de Barros EM, de Sá Brígido J, da Silva WM, Rocha MVP, Gonçalves LRB (2016) The bioconversion of pretreated cashew apple bagasse into ethanol by SHF and SSF processes. Appl Biochem Biotechnol 178:1167–1183. https://doi.org/10.1007/s12010-015-1936-0

Hasunuma T, Kondo A (2012) Consolidated bioprocessing and simultaneous saccharification and fermentation of lignocellulose to ethanol with thermotolerant yeast strains. Process Biochem 47:1287–1294. https://doi.org/10.1016/j.procbio.2012.05.004

Tomás-Pejó E, Oliva JM, Ballesteros M, Olsson L (2008) Comparison of SHF and SSF processes from steam-exploded wheat straw for ethanol production by xylose-fermenting and robust glucose-fermenting Saccharomyces cerevisiae strains. Biotechnol Bioeng 100:1122–1131. https://doi.org/10.1002/bit.21849

Romaní A, Ruiz HA, Teixeira JA, Domingues L (2016) Valorization of Eucalyptus wood by glycerol-organosolv pretreatment within the biorefinery concept: an integrated and intensified approach. Renew Energy 95:1–9. https://doi.org/10.1016/j.renene.2016.03.106

Manzanares P, Negro MJ, Oliva JM, Saéz F, Ballesteros I, Ballesteros M, Cara C, Castro E, Ruiz E (2011) Different process configurations for bioethanol production from pretreated olive pruning biomass. J Chem Technol Biotechnol 86:881–887. https://doi.org/10.1002/jctb.2604

Alvira P, Gyalai-Korpos M, Barta Z, Oliva JM, Réczey K, Ballesteros M (2013) Production and hydrolytic efficiency of enzymes from Trichoderma reesei RUTC30 using steam pretreated wheat straw as carbon source. J Chem Technol Biotechnol 88:1150–1156. https://doi.org/10.1002/jctb.3955

Moreno AD, Ibarra D, Ballesteros I, Fernández JL, Ballesteros M (2013) Ethanol from laccase-detoxified lignocellulose by the thermotolerant yeast Kluyveromyces marxianus—effects of steam pretreatment conditions, process configurations and substrate loadings. Biochem Eng J 79:94–103. https://doi.org/10.1016/j.bej.2013.07.006

Happi Emaga T, Andrianaivo RH, Wathelet B, Tchango JT, Paquot M (2007) Effects of the stage of maturation and varieties on the chemical composition of banana and plantain peels. Food Chem 103:590–600. https://doi.org/10.1016/j.foodchem.2006.09.006

Happi Emaga T, Ronkart SN, Robert C, Wathelet B, Paquot M (2008) Characterisation of pectins extracted from banana peels (Musa AAA) under different conditions using an experimental design. Food Chem 108:463–471. https://doi.org/10.1016/j.foodchem.2007.10.078

NREL (2007) Chemical analysis and testing laboratory analytical procedures. National Renewable Energy Laboratory, Golden

Gonçalves FA, Ruiz HA, dos Santos ES, Teixeira JA, de Macedo GR (2015) Bioethanol production from coconuts and cactus pretreated by autohydrolysis. Ind Crop Prod 77:1–12. https://doi.org/10.1016/j.indcrop.2015.06.041

Sánchez C (2009) Lignocellulosic residues: biodegradation and bioconversion by fungi. Biotechnol Adv 27:185–194. https://doi.org/10.1016/j.biotechadv.2008.11.001

Pereira FB, Romaní A, Ruiz HA, Teixeira JA, Domingues L (2014) Industrial robust yeast isolates with great potential for fermentation of lignocellulosic biomass. Bioresour Technol 161:192–199. https://doi.org/10.1016/j.biortech.2014.03.043

Huffer S, Clark ME, Ning JC, Blanch HW, Clark DS (2011) Role of alcohols in growth, lipid composition, and membrane fluidity of yeasts, bacteria, and archaea. Appl Environ Microbiol 77(18):6400–6408. https://doi.org/10.1128/AEM.00694-11

Fu X, Li P, Zhang L, Li S (2019) Understanding the stress responses of Kluyveromyces marxianus after an arrest during high-temperature ethanol fermentation based on integration of RNA-Seq and metabolite data. Appl Microbiol Biotechnol 103:2715–2729. https://doi.org/10.1007/s00253-019-09637-x

Westman JO, Taherzadeh MJ, Franzén CJ (2012) Inhibitor tolerance and flocculation of a yeast strain suitable for second generation bioethanol production. Electron J Biotechnol 15:5–6. https://doi.org/10.2225/vol15-issue3-fulltext-8

De Souza PK, Sellin N, Souza O, Marangoni C (2013) Simulation of dilute acid hydrolysis of banana waste for ethanol production: comparison between the use of fruits, peel and pseudostem. Chem Eng Trans 32:1141–1146. https://doi.org/10.3303/CET1332191

Oliva JM, Ballesteros I, Negro MJ, Manzanares P, Cabañas A, Ballesteros M (2004) Effect of binary combinations of selected toxic compounds on growth and fermentation of Kluyveromyces marxianus. Biotechnol Prog 20:715–720. https://doi.org/10.1021/bp034317p

Oliva JM, Negro MJ, Sáez F, Ballesteros I, Manzanares P, González A, Ballesteros M (2006) Effects of acetic acid, furfural and catechol combinations on ethanol fermentation of Kluyveromyces marxianus. Process Biochem 41:1223–1228. https://doi.org/10.1016/j.procbio.2005.12.003

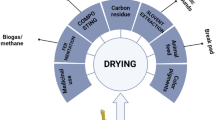

Palacios-Ponce S, Ilyina A, Ramos-González R, Ruiz HA, Martínez-Hernández JL, Segura-Ceniceros EP, Aguilar MA, Sánchez O, Aguilar CN (2018) Bioproducts obtained from the bioprocessing of the banana peel waste: an overview. In: Applied Chemistry and Chemical Engineering, Vol. 5: Research Methodologies in Modern Chemistry and Applied Science. Part II - 10 (Eds: Haghi AK, Faria Ribeiro AC, Pogliani L, Balköse D, Torrens F, Mukbaniani OV). CRC Press, Apple Academic Press Icn, Tylor and Francys Group. 223–250 pp

Watanabe T, Srichuwong S, Arakane M, Tamiya S, Yoshinaga M, Watanabe I, Yamamoto M, Ando A. Tokuyasu K, Nakamura T (2010) Selection of stress-tolerant yeasts for simultaneous saccharification and fermentation (SSF) of very high gravity (VHG) potato mash to ethanol. Bioresour Technol 101:9710–9714. https://doi.org/10.1016/j.biortech.2010.07.079

Mesa L, González E, Romero I, Ruiz E, Cara C, Castro E (2011) Comparison of process configurations for ethanol production from two-step pretreated sugarcane bagasse. Chem Eng J 175:185–191. https://doi.org/10.1016/j.cej.2011.09.092

Acknowledgments

The authors thank the Mexican National Council of Science and Technology (CONACYT) for the financial support at the project PDCPN 2013-01-213844, Ph.D. scholarship (No.560315), and the financial support under the program “Cátedras-CONACyT” (Project No. 729).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Palacios, A.S., Ilyina, A., Ramos-González, R. et al. Ethanol production from banana peels at high pretreated substrate loading: comparison of two operational strategies. Biomass Conv. Bioref. 11, 1587–1596 (2021). https://doi.org/10.1007/s13399-019-00562-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00562-7