Abstract

As semiconductor device scaling faces a severe technical bottleneck, vertical die stacking technologies have been developed to obtain high performance, high density, low latency, cost effectiveness and a small form factor. This stacking technology is receiving great attention from industry as a core technology from the point of view of recent heterogeneous integration technology. Most importantly, bonding using copper is aggressively studied to stack various wafers or dies and realize genuine three-dimensional packaging. Copper is emerging as the most attractive bonding material due to its fine-pitch patternability and high electrical performance with a CMOS-friendly process. Unfortunately, copper is quickly oxidized, and a high bonding temperature is required for complete Cu bonding, which greatly exceeds the thermal budget for the packaging process. Additionally, the size of Cu pads is decreasing to increase the density of interconnections. Therefore, various copper bonding methods have been studied to realize copper oxidation prevention, a low bonding temperature, and a fine-pitch Cu pad structure with a high density. Furthermore, recently, hybrid bonding, which refers to the simultaneous bonding of copper pads and surrounding dielectrics, has been considered a possible solution for advanced bonding technology. This paper reviews recent studies on various copper bonding technologies, including Cu/oxide hybrid bonding.

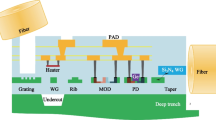

Graphical Abstract

© The Electrochemical Society. Reproduced with permission from IOP Publishing. All rights reserved)

Similar content being viewed by others

References

Lee, S., Jee, Y., Park, S., Lee, S., Hwang, B., Jo, G., Lee, C., Park, J., Jang, A., Jung, H. C., Kim, I., Kang, D., Baek, S., Kim, D.W., Kang, U.: A study on memory stack process by hybrid copper bonding (HCB) technology. In: IEEE 72nd ECTC, pp. 1085–1089 (2022). https://doi.org/10.1109/ECTC51906.2022.00175

Agarwal, R., Cheng, P., Shah, P., Wilkerson, B., Swaminathan, R., Wuu, J., Mandalapu, C.: 3D packaging for heterogeneous integration. In: IEEE 72nd ECTC, pp. 1103–1107 (2022). https://doi.org/10.1109/ECTC51906.2022.00178

Iacovo, S., Nagano, F., Channam, V.S.K., Walsby, E., Crook, K., Buchanan, K., Jourdain, A., Vanstreels, K., Phommahaxay, A., Beyne, E.: Direct bonding using low temperature SiCN dielectrics. In: IEEE 72nd ECTC, pp. 602–607 (2022). https://doi.org/10.1109/ECTC51906.2022.00101

Weng, M.W., Mao, S.Y., Liu, D., Hu, H.W., Chen, K.N.: Asymmetric low temperature cu-polymer hybrid bonding with Au passivation layer. In: VLSI-TSA, pp. 2021–2022 (2021). https://doi.org/10.1109/VLSI-TSA51926.2021.9440101

Panigrahy, A.K., Chen, K.: Low temperature Cu–Cu bonding Technology in three dimensional integration: an extensive review. J. Electron. Packag. 140, 010801 (2018). https://doi.org/10.1115/1.4038392

Das, S., Chandrakasan, A.P., Reif, R.: Calibration of rent’s rule models for three-dimensional integrated circuits. IEEE Trans. Very Large Scale Integr. Syst. 12, 359–366 (2004). https://doi.org/10.1109/TVLSI.2004.825833

Chen, K.N., Tan, C.S., Fan, A., Reif, R.: Abnormal contact resistance reduction of bonded copper interconnects in three-dimensional integration during current stressing. Appl. Phys. Lett. 86, 011903 (2005). https://doi.org/10.1063/1.1844609

Farooq, M.G., Iyer, S.S.: 3D integration review. Sci. China Inf. Sci. 54, 1012–1025 (2011). https://doi.org/10.1007/s11432-011-4226-7

Park, H., Kim, S.E.: Nitrogen passivation formation on Cu surface by Ar–N2 plasma for Cu-to-Cu wafer stacking application. Microsyst. Technol. 25, 3847–3855 (2019). https://doi.org/10.1007/s00542-018-4254-y

Sikka, K., Bonam, R., Liu, Y., Andry, P., Parekh, D., Jain, A., Bergendahl, M., Divakaruni, R., Cournoyer, M., Gagnon, P., Dufort, C., Sousa, I., Zhang, H., Cropp, E., Wassick, T., Mori, H., Kohara, S.: Direct bonded heterogeneous integration (DBHI) Si bridge. In: IEEE 71st ECTC, pp. 136–147 (2021). https://doi.org/10.1109/ECTC32696.2021.00034

Elsherbini, A., Liff, S., Swan, J., Jun, K., Tiagaraj, S., Pasdast, G.: Hybrid bonding interconnect for advanced heterogeneously integrated processors. In: IEEE 71st ECTC, pp. 1014–1019 (2021). https://doi.org/10.1109/ECTC32696.2021.00166

Park, H., Kim, S.E.: Two-step plasma treatment on copper surface for low-temperature Cu thermo-compression bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 10, 332–338 (2020). https://doi.org/10.1109/TCPMT.2019.2928323

Zhang, S., Li, Z., Zhou, H., Li, R., Wang, S., Paik, K.-W., He, P.: Challenges and recent prospectives of 3D heterogeneous integration. In: E-Prime-Advances in Electrical Engineering, Electronics and Energy, vol. 2, p. 100052 (2022). https://doi.org/10.1016/j.prime.2022.100052

Ren, H., Yang, Y.T., Iyer, S.S.: Recess effect study and process optimization of sub-10 μm pitch die-to-wafer hybrid bonding. In: IEEE 72nd ECTC, pp. 149–156 (2022). https://doi.org/10.1109/ECTC51906.2022.00034

Murugesan, M., Mori, K., Sawa, M., Sone, E., Koyanagi, M., Fukushima, T.: Cu–SiO2 hybrid bonding yield enhancement through Cu grain enlargement. In: IEEE 72nd ECTC, pp. 685–690 (2022). https://doi.org/10.1109/ECTC51906.2022.00115

Kim, M.K., Park, S., Jang, A., Lee, H., Baek, S., Lee, C.S., Kim, I., Park, J., Jee, Y., Kang, U.B., Kim, D.W.: Characterization of die-to-wafer hybrid bonding using heterogeneous dielectrics. In: IEEE 72nd ECTC, pp. 335–339 (2022). https://doi.org/10.1109/ECTC51906.2022.00062

Chiu, W.L., Lee, O.H., Chiang, C.W., Chang, H.H.: Low-Temperature wafer-to-wafer hybrid bonding by nanocrystalline copper. In: IEEE 72nd ECTC, pp. 679–684 (2022). https://doi.org/10.1109/ECTC51906.2022.00114

Park, H., Seo, H., Kim, S.E.: Anti-oxidant copper layer by remote mode N2 plasma for low temperature copper–copper bonding. Sci. Rep. 10, 21720 (2020). https://doi.org/10.1038/s41598-020-78396-x

Seo, H., Park, H., Kim, S.E.: Comprehensive analysis of a Cu nitride passivated surface that enhances Cu-to-Cu bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 10, 1814–1820 (2020). https://doi.org/10.1109/TCPMT.2020.3024998

Bajwa, A.A., Jangam, S., Pal, S., Marathe, N., Bai, T., Fukushima, T., Goorsky, M., Iyer, S.S.: Heterogeneous integration at fine pitch (10 μm) using thermal compression bonding. In: IEEE 67th ECTC, pp. 1276–1284 (2017). https://doi.org/10.1109/ECTC.2017.240

Tan, C.S., Peng, L., Fan, J., Li, H., Gao, S.: Three-dimensional wafer stacking using Cu–Cu bonding for simultaneous formation of electrical, mechanical, and hermetic bonds. IEEE Trans. Dev. Mater. Reliab. 12, 194–200 (2012). https://doi.org/10.1109/TDMR.2012.2188802

Liu, C., Lin, H., Huang, Y., Chu, Y., Chen, C., Lyu, D., Chen, K., Tu, K.: Low-temperature direct copper-toc-opper bonding enabled by creep on (111) surfaces of nano-twinned Cu. Sci. Rep. 5, 09734 (2015). https://doi.org/10.1038/srep09734

Rebhan, B., Plach, T., Tollabimazraehno, S., Dragoi, V., Kawano, M.: Cu–Cu wafer bonding: an enabling technology for three-dimensional integration. In: IEEE ICEP, pp. 475–479 (2014). https://doi.org/10.1109/ICEP.2014.6826724

Morrow, P.R., Park, C., Ramanathan, S., Kobrinsky, M.J., Harmes, M.: Three-dimensional wafer stacking via Cu–Cu bonding integrated with 65-nm strained-Si/low-k CMOS technology. IEEE Electron Dev. Lett. 27, 335–337 (2006). https://doi.org/10.1109/LED.2006.873424

Li, M., Breeden, M., Wang, V., Hollin, J., Linn, N.M.K., Winter, C.H., Kummel, A., Bakir, M.S.: Cu–Cu bonding using selective cobalt atomic layer deposition for 25-D/3-D chip integration technologies. IEEE Trans. Compon. Packag. Manuf. Technol. 10, 2125–2128 (2020). https://doi.org/10.1109/TCPMT.2020.3033257

Panigrahy, A.K., Bonam, S., Ghosh, T., Vanjari, S.R.K., Singh, S.G.: Diffusion enhanced drive sub 100 °C wafer level fine-pitch Cu–Cu thermocompression bonding for 3D IC integration. In: IEEE 69th ECTC, pp. 2156–2161 (2019). https://doi.org/10.1109/ECTC.2019.00-24

Beilliard, Y., Moreau, S., Di Cioccio, D., Coudrain, P., Romano, G., Nowodzinski, A., Aussenac, F., Jouneau, P., Rolland, E., Signamarcheix, T.: Advances toward reliable high density Cu–Cu interconnects by Cu-SiO2 direct hybrid bonding. In: IEEE International 3D Systems Integration Conference (2014). https://doi.org/10.1109/3DIC.2014.7274306

Gao, G., Mirksrim, L., Fountain, G., Suwito, D., Theil, J., Workman, T., Uzoh, C., Guevara, G., Lee, B., Huyhn, M., Mrozek, P.: Low temperature hybrid bonding for die to wafer stacking applications. In: IEEE 71st ECTC, pp. 383–389 (2021). https://doi.org/10.1109/ECTC32696.2021.00071

Enquist, P., Fountain, G., Petteway, C., Hollingsworth, A., Grady, H.: Low cost of ownership scalable copper direct bond interconnect 3D IC technology for three dimensional integrated circuit applications. In: EEE International 3D Systems Integration Conference (2009). https://doi.org/10.1109/3DIC.2009.5306533

Fujino, M., Takahashi, K., Araga, Y., Kikuchi, K.: 300 mm wafer-level hybrid bonding for Cu/interlayer dielectric bonding in vacuum. Jpn. J. Appl. Phys. 59, SBBA02 (2020). https://doi.org/10.7567/1347-4065/ab4b2b

Theil, J.A., Mirkarimi, L, Fountain, G., Gao, G., Katkar, R.: Recent development in fine pitch wafer-to-wafer hybrid bonding with copper interconnect. In: IEEE IWLPC (2019). https://doi.org/10.23919/IWLPC.2019.8913862

Lu, C., Jhu, S., Chen, C., Tsai, B., Chen, K.: Asymmetric wafer-level polyimide and Cu/Sn hybrid bonding for 3-D heterogeneous integration. IEEE Trans. Electron. Dev. 66, 3073–3079 (2019). https://doi.org/10.1109/TED.2019.2915332

Hsiao, Z., Ko, C., Chang, H., Fu, H., Chiang, C., Hsu, C., Shen, W., Lo, W.: Cu/BCB hybrid bonding with TSV for 3D integration by using fly cutting technology. In: IEEE ICEP-IAAC, pp. 834–837 (2015). https://doi.org/10.1109/ICEP-IAAC.2015.7111128

Chidambaram, V., Lianto, P., Wang, X., See, G., Wiswell, N., Kawano, M.: Dielectric materials characterization for hybrid bonding. In: IEEE 71st ECTC, pp. 426–431 (2021). https://doi.org/10.1109/ECTC32696.2021.00078

Jangam, S.C., Adeel Bajwa, A., Mogera, U., Ambhore, P., Colosimo, T., Chylak, B., Iyer, S.S.: Fine-pitch (≤ 10 µm) direct Cu–Cu interconnects using in-situ formic acid vapor treatment. In: IEEE 69th ECTC, pp. 620–627 (2019). https://doi.org/10.1109/ECTC.2019.00099

Chen, K.N., Fan, A., Tan, C.S., Reif, R.: Temperature and duration effects on microstructure evolution during copper wafer bonding. J. Electron. Mater. 32(12), 1371–1374 (2003). https://doi.org/10.1007/s11664-003-0103-5

Shie, K., Juang, J., Chen, C.: Instant Cu-to-Cu direct bonding enabled by <111>-oriented nano-twinned Cu bumps. Jpn. J. Appl. Phys. 59, SBBA03 (2020). https://doi.org/10.7567/1347-4065/ab5697

Kim, S., Kang, P., Kim, T., Lee, K., Jang, J., Moon, K., Na, H., Hyun, S., Hwang, K.: Cu microstructure of high density Cu hybrid bonding interconnection. In: IEEE 69th ECTC, pp. 636–641 (2019). https://doi.org/10.1109/ECTC.2019.00101

Kim, S.E., Kim, S.: Wafer level Cu–Cu direct bonding for 3D integration. Microelectron. Eng. 137, 158–163 (2015). https://doi.org/10.1016/j.mee.2014.12.012

Kwon, Y., Jindal, A., McMahon, J.J., Lu, J.Q., Gutmann, R.J., Cale, T.S.: Dielectric glue wafer bonding for 3D ICs. Mater. Res. Soc. Symp. Proc. 766, 27–32 (2003). https://doi.org/10.1557/PROC-766-E5.8

Lü, J.Q., Kwon, Y., Kraft, R.P., Gutmann, R.J., McDonald, J.F., Gale, T.S.: Stacked chip-to-chip interconnections using wafer bonding technology with dielectric bonding glues. In: IEEE IITC, pp. 219–221 (2001). https://doi.org/10.1109/IITC.2001.930066

Timothy, J.L., Ronald, C., Kwon, Y., Seok, J., Lu, J., Cale, T., Gutmann, R.: A study on the bond strength of BCB-bonded wafers. Korean Chem. Eng. Res. 45(5), 479–486 (2007)

Burns, J.A., Aull, B.F., Chen, C.K., Chen, C.L., Keast, C.L., Knecht, J.M., Suntharalingam, V., Warner, K., Wyatt, P.W., Yost, D.R.W.: A wafer-scale 3-D circuit integration technology. IEEE Trans. Electron. Dev. 53(10), 2507–2516 (2006). https://doi.org/10.1109/TED.2006.882043

Fan, A., Rahman, A., Reif, R.: Copper wafer bonding. Electrochem. Solid State Lett. 2(10), 534–536 (1999). https://doi.org/10.1149/1.1390894

Panigrahi, A.K., Bonam, S., Ghosh, T., Vanjari, S.R.K., Singh, S.G.: Diffusion enhanced drive sub 100 °C wafer level fine-pitch Cu–Cu thermocompression bonding for 3D IC integration. In: IEEE 69th ECTC, pp. 2156–2161 (2019). https://doi.org/10.1109/ECTC.2019.00-24

Panigrahi, A.K., Ghosh, T., Vanjari, S.R.K., Singh, S.G.: Surface density gradient engineering precedes enhanced diffusion; drives CMOS in-line process flow compatible Cu–Cu thermocompression bonding at 75 °C. IEEE Trans. Dev. Mater. Reliab. 19, 791–795 (2019). https://doi.org/10.1109/TDMR.2019.2952927

Juang, J.Y., Lu, C.L., Chen, K.J., Chen, C.C.A., Hsu, P.N., Chen, C., Tu, K.N.: Copper-to-copper direct bonding on highly (111)-oriented nanotwinned copper in no-vacuum ambient. Sci. Rep. 8(1), 1–11 (2018). https://doi.org/10.1109/IMPACT.2017.8255959

Liu, C.M., Lin, H.W., Huang, Y.S., Chu, Y.C., Chen, C., Lyu, D.R., Chen, K.N., Tu, K.N.: Low-temperature direct copper-to-copper bonding enabled by creep on (111) surfaces of nanotwinned Cu. Sci. Rep. 5, 1–11 (2015). https://doi.org/10.1038/srep09734

Kim, S., Nam, Y., Kim, S.E.: Effects of forming gas plasma treatment on low-temperature Cu–Cu direct bonding. Jpn. J. Appl. Phys. 55, 06JC02 (2016). https://doi.org/10.7567/JJAP.55.06JC02

Chiang, P., Liang, S., Song, J., Huang, S., Chiu, Y., Hung, C.: Enhanced Cu-to-Cu direct bonding by controlling surface physical properties. Jpn. J. Appl. Phys. 56, 035503 (2017). https://doi.org/10.7567/JJAP.56.035503

Takagi, H., Kikuchi, K., Maeda, R., Chung, R.T., Suga, R.: Surface activated bonding of Silicon wafers at room temperature. Appl. Phys. Lett. 68, 2222–2224 (1996). https://doi.org/10.1063/1.115865

Gao, R., He, S., Li, J., Shen, Y., Nishikawa, H.: Interfacial transformation of preoxidized Cu microparticles in a formic-acid atmosphere for pressureless Cu–Cu bonding. J. Mater. Sci. Mater. Electron. 31, 14635–14644 (2020). https://doi.org/10.1007/s10854-020-04026-x

Park, H., Seo, H., Kim, S.E.: Characteristics of copper nitride nanolayer used in 3D Cu bonding interconnects. Electron. Mater. Lett. 17, 392–398 (2021). https://doi.org/10.1007/s13391-021-00299-4

Chua, S.L., Chan, J.M., Goh, S.C., Tan, C.S.: Cu–Cu bonding in ambient environment by Ar/N2 plasma surface activation and its characterization. IEEE Trans. Comp. Packag. Manuf. Technol. 9, 596–605 (2019). https://doi.org/10.1109/TCPMT.2018.2875460

Hu, L., Goh, S.C.K., Tan, C.S.: Ar/N2 plasma induced metastable CuxNy for Cu–Cu direct bonding. ECS Trans. 98, 203–210 (2020). https://doi.org/10.1149/09804.0203ecst

Park, H., Seo, H., Kim, Y., Park, S., Kim, S.E.: Low-temperature (260 °C) solderless Cu–Cu bonding for fine-pitch 3-D packaging and heterogeneous integration. IEEE Trans. Comp. Packag. Manuf. Technol. 11, 565–572 (2021). https://doi.org/10.1109/TCPMT.2021.3065531

Park, J., Kim, J., Park, Y.: Effects of wet treatment conditions and pattern densities on interfacial bonding characteristics of Cu–Cu direct bonds. Jpn. J. Appl. Phys. 53, 05HB07 (2014). https://doi.org/10.7567/JJAP.53.05HB07

Lim, D.F., Wei, J., Leong, K.C., Tan, C.S.: Cu passivation for enhanced low temperature (< 300 °C) bonding in 3D integration. Microelectron. Eng. 106, 144–148 (2013). https://doi.org/10.1016/j.mee.2013.01.032

Peng, J., Chen, B., Wang, Z., Guo, J., Wu, B., Hao, S., Zhang, Q., Gu, L., Zhou, Q., Liu, Z., Hong, S., You, S., Fu, A., Shi, Z., Xie, H., Cao, D., Lin, C., Fu, G., Zheng, L., Jiang, Y., Zheng, N.: Surface coordination layer passivates oxidation of copper. Nature 586, 390 (2020). https://doi.org/10.1038/s41586-020-2783-x

Liang, S., Song, J., Huang, S., Chiu, Y., Tarng, D., Hung, C.: Light enhanced direct Cu bonding for advanced electronic assembly. J. Mater. Sci. Mater. Electron. 29, 14144–14150 (2018). https://doi.org/10.1007/s10854-018-9547-5

Tan, C.S., Lim, D.F.: Cu surface passivation with self-assembled monolayer (SAM) and its application for wafer bonding at moderately low temperature. ECS Trans. 50, 115–123 (2012). https://doi.org/10.1149/05007.0115ecst

Peng, L., Li, H.Y., Lim, D.F., Gao, S., Tan, C.S.: Thermal reliability of fine pitch Cu–Cu bonding with self assembled monolayer (SAM) passivation for wafer-on-wafer 3D-stacking. In: IEEE 61st ECTC, pp. 22–26 (2011). https://doi.org/10.1109/ECTC.2011.5898485

Tan, C.S., Lim, D.F., Ang, X.F., Wei, J., Leong, K.C.: Low temperature Cu–Cu thermo-compression bonding with temporary passivation of self-assembled monolayer and its bond strength enhancement. Microelectron. Reliab. 52, 321–324 (2012). https://doi.org/10.1016/j.microrel.2011.04.003

Lykova, M., Panchenko, I., Künzelmann, U., Reif, J., Geidel, M., Wolf, M.J., Lang, K.: Characterisation of Cu/Cu bonding using self-assembled monolayer. Solder. Surf. Mt. Technol. 30, 106–111 (2018). https://doi.org/10.1016/j.mee.2018.09.008

Ma, Y., Roshanghias, A., Binder, A.: A comparative study on direct Cu–Cu bonding methodologies for copper pillar bumped flip-chips. J. Mater. Sci. Mater. Electron. 29, 9347–9353 (2018). https://doi.org/10.1007/s10854-018-8965-8

Li, J., Liang, Q., Shi, T., Fan, J., Gong, B., Feng, C., Fan, J., Liao, G., Tang, Z.: Design of Cu nanoaggregates composed of ultra-small Cu nanoparticles for Cu–Cu thermocompression bonding. J. Alloys Compd. 772, 793–800 (2019). https://doi.org/10.1016/j.jallcom.2018.09.115

Mou, Y., Peng, Y., Zhang, Y., Cheng, H., Chen, M.: Cu–Cu bonding enhancement at low temperature by using carboxylic acid surface-modified Cu nanoparticles. Mater. Lett. 227, 179–183 (2018). https://doi.org/10.1016/j.matlet.2018.05.037

Zuo, Y., Shen, J., Hu, Y., Gao, R.: Improvement of oxidation resistance and bonding strength of Cu nanoparticles solder joints of Cu–Cu bonding by phosphating the nanoparticle. J. Mater. Proc. Technol. 253, 27–33 (2018). https://doi.org/10.1016/j.jmatprotec.2017.11.001

Gao, R., Li, J., Shen, Y., Nishikawa, H.: A Cu–Cu bonding method using preoxidized Cu microparticles under formic acid atmosphere. In: EEE ICEP, pp. 159–162 (2019). https://doi.org/10.23919/ICEP.2019.8733490

Liu, Z., Cai, J., Wang, Q., Liu, L., Zou, G.: Modified pulse laser deposition of Ag nanostructure as intermediate for low temperature Cu–Cu bonding. Appl. Surf. Sci. 445, 16–23 (2018). https://doi.org/10.1016/j.apsusc.2018.03.076

Liu, Z., Cai, J., Wang, Q., Wang, Z., Liu, L., Zou, G.: Thermal-stable void-free interface morphology and bonding mechanism of low-temperature Cu–Cu bonding using Ag nanostructure as intermediate. J. Alloys Compd. 767, 575–582 (2018). https://doi.org/10.1016/j.jallcom.2018.07.060

Wang, Q., Zhang, S., Lin, T., Zhang, P., He, P., Paik, K.W.: Highly mechanical and high-temperature properties of Cu–Cu joints using citrate-coated nanosized Ag paste in air. Progress Nat. Sci. Mater. Int. 31(1), 129–140 (2021). https://doi.org/10.1016/j.pnsc.2020.12.004

Zhang, S., Wang, Q., Lin, T., Zhang, P., He, P., Paik, K.W.: Cu–Cu joining using citrate coated ultra-small nano-silver pastes. J. Manuf. Process. 62, 546–554 (2021). https://doi.org/10.1016/j.jmapro.2020.11.043

Panigrahi, A.K., Bonam, S., Ghosh, T., Vanjari, S.R.K., Singh, S.G.: Low temperature, low pressure CMOS compatible Cu–Cu thermo-compression bonding with Ti passivation for 3D IC integration. In: IEEE 65th ECTC, pp. 2205–2210 (2015). https://doi.org/10.1109/ECTC.2015.7159909

Park, S., Kim, Y., Kim, S.E.: Low-temperature diffusion behavior of Ti in Cu/Ti–Ti/Cu bonding. J. Electron. Mater. 51, s2617-2623 (2022). https://doi.org/10.1007/s11664-022-09501-1

Panigrahi, A.K., Bonam, S., Ghosh, T., Singh, S.G., Vanjari, S.R.K.: Ultra-thin Ti passivation mediated breakthrough in high quality Cu–Cu bonding at low temperature and pressure. Mater. Lett. 169, 269–272 (2016). https://doi.org/10.1016/j.matlet.2016.01.126

Bonam, S., Panigrahi, A.K., Kumar, C.H., Vanjari, S.R.K., Singh, S.G.: Interface and reliability analysis of Au-passivated Cu–Cu fine-pitch thermocompression bonding for 3-D IC applications. IEEE Trans. Comp. Packag. Manuf. Technol. 9, 1227–1234 (2019). https://doi.org/10.1109/TCPMT.2019.2912891

Huang, Y., Chien, Y., Tzeng, R., Chen, K.: Demonstration and electrical performance of Cu–Cu bonding at 150 °C with Pd passivation. IEEE Trans. Electron. Dev. 62, 2587–2592 (2015). https://doi.org/10.1109/TED.2015.2446507

Liu, D., Kuo, T., Liu, Y., Hong, Z., Chung, Y., Chou, T., Hu, H., Chen, K.: Investigation of low-temperature Cu–Cu direct bonding with Pt passivation layer in 3-D integration. IEEE Trans. Comp. Packag. Manuf. Technol. 11, 573–578 (2021). https://doi.org/10.1109/TCPMT.2021.3069085

Kim, Y., Park, S., Kim, S.E.: The effect of an Ag nanofilm on low-temperature Cu/Ag–Ag/Cu chip bonding in air. Appl. Sci. 11, 9444 (2021). https://doi.org/10.3390/app11209444

Chou, T., Huang, S., Chen, P., Hu, H., Liu, D., Chang, C., Ni, T., Chen, C., Lin, Y., Chang, T., Chen, K.: Electrical and reliability investigation of Cu-to-Cu bonding with silver passivation layer in 3-D integration. IEEE Trans. Comp. Packag. Manuf. Technol. 11, 36–42 (2021). https://doi.org/10.1109/TCPMT.2020.3037365

Huang, Y.P., Chien, Y.S., Tzeng, R.N., Shy, M.S., Lin, T.H., Chen, K.H., Chiu, C.T., Chiou, J.C., Chuang, C.T., Hwang, W., Tong, H.M., Chen, K.N.: Novel Cu-to-Cu bonding with Ti passivation at 180 °C in 3-D integration. IEEE Electron. Dev. Lett. 34(12), 1551–1553 (2013). https://doi.org/10.1109/LED.2013.2285702

Panigrahi, A.K., Ghosh, T., Vanjari, S.R.K., Singh, S.G.: Oxidation resistive, CMOS compatible copper based alloy ultrathin films as a superior passivation mechanism for achieving 150 °C Cu–Cu wafer on wafer thermocompression bonding. IEEE Tans. Electron Dev. 64, 1239–1245 (2017). https://doi.org/10.1109/TED.2017.2653188

Panigrahi, A.K., Ghosh, T., Vanjari, S.R.K., Singh, S.G.: Demonstration of sub 150 °C Cu–Cu thermocompression bonding for 3D IC applications, utilizing an ultra-thin layer of Manganin alloy as an effective surface passivation layer. Mater. Lett. 194, 86–89 (2017). https://doi.org/10.1016/j.matlet.2017.02.041

Panigrahi, A.K., Kumar, C.H., Bonam, S., Ghosh, T., Vanjari, S.R.K., Singh, S.G.: Optimized ultra-thin manganin alloy passivated fine-pitch damascene compatible bump-less Cu–Cu bonding at sub 200 °C for three-dimensional Integration applications. Jpn. J. Appl. Phys. 57, 02BC04 (2018). https://doi.org/10.7567/JJAP.57.02BC04

Hong, Z.J., Liu, D., Hu, H.W., Cho, C.I., Weng, M.W., Liu, J.H., Chen, K.N.: Investigation of bonding mechanism for low-temperature Cu–Cu bonding with passivation layer. Appl. Surf. Sci. 592, 1–7 (2022). https://doi.org/10.1016/j.apsusc.2022.153243

Yang, Y., Chou, T., Yu, T., Chang, Y., Huang, T., Yang, K., Ko, C., Chen, Y., Tseng, T., Chen, K.: Low-temperature Cu–Cu direct bonding using pillar–concave structure in advanced 3-D heterogeneous integration. IEEE Trans. Comp. Packag. Manuf. Technol. 7, 1560–1566 (2017). https://doi.org/10.1109/TCPMT.2017.2720468

Elsherbini, A., Liff, S., Swan, J., Jun, K., Tiagaraj, S., Pasdast, G.: Hybrid bonding interconnect for advanced heterogeneously integrated processors. In: IEEE 71st ECTC, pp. 1014–1019 (2022). https://doi.org/10.1109/ECTC32696.2021.00166

Mirkarimi, L., Uzoh, C., Suwito, D., Lee, B., Fountain, G., Workman, T., Theil, J., Gao, G., Buckalew, B., Oberst, J., Ponnuswamy, T.: The influence of Cu microstructure on thermal budget in hybrid bonding. In: IEEE 72nd ECTC, pp. 162–167 (2022). https://doi.org/10.1109/ECTC51906.2022.00036

Sitaraman, S., Jiang, L., Dag, S., Masoomi, M., Wang, Y., Lianto, P., An, J., Wang, R., See, G., Sundarrajan, A., Bazizi, E.M., Ayyagari-Sangamalli, B.: A holistic development framework for hybrid bonding. In: IEEE 72nd ECTC, pp. 691–700 (2022). https://doi.org/10.1109/ECTC51906.2022.00116

Jouve, A., Balan, V., Bresson, N., Euvrard-Colnat, C., Fournel, F., Exbrayat, Y., Mauguen, G., Abdel Sater, M., Beitia, C., Arnaud, L., Cheramy, S., Lhostis, S., Farcy, A., Guillaumet, S., Mermoz, S.: 1μm Pitch direct hybrid bonding with < 300 nm wafer-to-wafer overlay accuracy. IEEE S3S, 1–2 (2018). https://doi.org/10.1109/S3S.2017.8309213

Sakuma, K., Yu, R., Belyansky, M., Bergendahl, M.A., Gomez, J.M., Skordas, S., Knickerbocker, J., McHerron, D., Li, M., Cheung, Y.M., Cheung So, S., Kwok, S.Y., Ho Fan, C., Lau, S.W.: Surface energy characterization for die-level Cu hybrid bonding. In: IEEE 72nd ECTC, pp. 312–316 (2022). https://doi.org/10.1109/ECTC51906.2022.00058

Naffziger, S., Beck, N., Burd, T., Lepak, K., Loh, G.H., Subramony, M., White, S.: Pioneering chiplet technology and design for the AMD EPYCTM and RyzenTM processor families: Industrial product. In: IEEE 48th ISCA, pp. 57–70 (2021). https://doi.org/10.1109/ISCA52012.2021.00014

Bond, A., Bourjot, E., Borel, S., Enot, T., Montmeat, P., Sanchez, L., Fournel, F., Swan, J.: Collective die-to-wafer self-assembly for high alignment accuracy and high throughput 3D integration. In: IEEE 72nd ECTC, pp. 168–176 (2022). https://doi.org/10.1109/ECTC51906.2022.00037

Wang, C.T., Lin, C.C., Lu, C.H., Chen, W.T., Tsai, C.H., Yu, D.C.H.: SoIC_H technology for heterogenous system integration. In: VLSI-TSA, pp. 258–259 (2022). https://doi.org/10.1109/VLSITechnologyandCir46769.2022.9830182

Park, J., Lee, B., Lee, H., Lim, D., Kang, J., Cho, C., Na, M., Jin, I.: Wafer to wafer hybrid bonding for DRAM applications. In: IEEE 72nd ECTC, pp. 126–129 (2022). https://doi.org/10.1109/ECTC51906.2022.00030

Shirasaka, T., Okuda, T., Shibata, T., Yoneda, S., Matsukawa, D., Mariappan, M., Koyanagi, M., Fukushima, T.: Comprehensive study on advanced chip on wafer hybrid bonding with copper/polyimide systems. In: IEEE 72nd ECTC, pp. 317–323 (2022). https://doi.org/10.1109/ECTC51906.2022.00059

Theil, J.A., Workman, T., Suwito, D., Mirkarimi, L., Fountain, G., Bang, K.M., Gao, G., Lee, B., Mrozek, P., Uzoh, C., Huynh, M., Zhao, O.: Analysis of die edge bond pads in hybrid bonded multi-die stacks. In: IEEE 72nd ECTC, pp. 130–136 (2022). https://doi.org/10.1109/ECTC51906.2022.00031

Hu, Z., Qu, X., Lin, H., Huang, R., Ge, X., Li, M., Chen, S., Zhao, Y.: Cu CMP process development and characterization of Cu dishing with 1.8 μm Cu pad and 3.6 μm pitch in Cu/SiO2 hybrid bonding. Jpn. J. Appl. Phys. 58, SHHC01 (2019). https://doi.org/10.7567/1347-4065/ab17c4

Rim, D., Lee, B., Park, J., Cho, C., Kang, J., Jin, I.: The wafer bonding yield improvement through control of SiCN Film composition and Cu pad shape. In: IEEE 72nd ECTC, pp. 674–678 (2022). https://doi.org/10.1109/ECTC51906.2022.00113

Workman, T., Mirkarimi, L., Theil, J., Foumain, G., Bang, K., Lee, B., Uzoh, C., Suwito, D., Gao, G., Mrozek, P.: Die to wafer hybrid bonding and fine pitch considerations. In: IEEE 71st ECTC, pp. 2071–2077 (2021). https://doi.org/10.1109/ECTC32696.2021.00326

Enquist, P., Fountain, G., Petteway, C., Hollingsworth, A., Grady, H.: Low cost of ownership scalable copper direct bond interconnect 3D IC technology for three dimensional integrated circuit applications. In: IEEE International Conference on 3D System Integration, vol. 919, pp. 1–6 (2009). https://doi.org/10.1109/3DIC.2009.5306533

Gao, G., Mirkarimi, L., Workman, T., Fountain, G., Theil, J., Guevara, G., Liu, P., Lee, B., Mrozek, P., Huynh, M., Rudolph, C., Werner, T., & Hanisch, A.: Low temperature Cu interconnect with chip to wafer hybrid bonding. In: IEEE 69th ECTC, pp. 628–635 (2019). https://doi.org/10.1109/ECTC.2019.00100

Liu, Z., Cai, J., Wang, Q., Tan, L., Hua, Y.: Low temperature Cu–Cu bonding using Ag nanostructure for 3D integration. ECS Solid State Lett. 4, 75–76 (2015). https://doi.org/10.1149/2.0061510ssl

Rudolph, C., Hamisch, A., Voigrlander, M., Cansauer, P., Wachsmuth, H., Kuttler, S., Wittler, O., Werner, T., Panchenko, I., Wolf, M.J.: Enabling D2W/D2D hybrid bonding on manufacturing equipment based on simulated process parameters. In: IEEE 71st ECTC, pp. 40–44 (2021). https://doi.org/10.1109/ECTC32696.2021.00018

Lin Ji, L., Che, F.X., Ji, H.M., Li, H.Y., Kawano, M.: Wafer-to-wafer hybrid bonding development by advanced finite element modeling for 3-D IC packages. IEEE Trans. Compon. Packag. Manuf. Technol. 10, 2106–2117 (2020). https://doi.org/10.1109/TCPMT.2020.3035652

Kagawa, Y., Kamibayashi, T., Yamano, Y., Nishio, K., Sakamoto, A., Yamada, T., Shimizu, K., Hirano, T., Iwamoto, H.: Development of face-to-face and face-to-back ultra-fine pitch Cu–Cu hybrid bonding. In: IEEE 72nd ECTC, pp. 306–311 (2022). https://doi.org/10.1109/ECTC51906.2022.00057

Beilliard, Y., Estevez, R., Parrya, G., McGarry, P., Di Cioccio, L., Coudrain, P.: Thermomechanical finite element modeling of Cu–SiO2 direct hybrid bonding with a dishing effect on Cu surfaces. Int. J. Solids Struct. 117, 208–220 (2017). https://doi.org/10.1016/j.ijsolstr.2016.02.041

Fukushima, T., Hashiguchi, H., Yonekura, H., Kino, H., Murugesan, M., Bea, J.C., Lee, K.W., Tanaka, T., Koyanagi, M.: Oxide-oxide thermocompression direct bonding technologies with capillary self-assembly for multichip-to-wafer heterogeneous 3D system integration. Micromachines 7, 10 (2016). https://doi.org/10.3390/mi7100184

Inoue, F., Peng, L., Iacovo, S., Phommahaxay, A., Verdonck, P., Meersschaut, J., Dara, P., Sleeckx, E., Miller, A., Beyer, G., Beyne, E.: Influence of composition of SiCN as interfacial layer on plasma activated direct bonding. ECS J. Solid State Sci. Technol. 8(6), 346–350 (2019). https://doi.org/10.1149/2.0241906jss

Beyne, E., Kim, S., Peng, L., Heylen, N., Messemaeker, J. De, Okudur, O.O., Phommahaxay, A., Kim, T., Stucchi, M., Velenis, D., Miller, A., Beyer, G.: Scalable , sub 2 μm Pitch, Cu/SiCN to Cu/SiCN hybrid wafer-to-wafer bonding technology. In: IEEE IEDM, pp. 729–732 (2017). https://doi.org/10.1109/IEDM.2017.8268486

Kim, S.W., Fodor, F., Heylen, N., Iacovo, S., De Vos, J., Miller, A., Beyer, G., Beyne, E.: Novel Cu/SiCN surface topography control for 1 μm pitch hybrid wafer-to-wafer bonding. In: IEEE 70th ECTC, pp. 216–222 (2020). https://doi.org/10.1109/ECTC32862.2020.00046

Sakuma, K., Yu, R., Belyansky, M., Bergendahl, M.A., Gomez, J., Knickerbocker, J., Mcherron, D., Li, M., Cheung, Y.M., So, S.C.: Surface energy characterization for die-level Cu hybrid bonding. In: IEEE 72nd ECTC, pp. 312–316 (2022). https://doi.org/10.1109/ECTC51906.2022.00058

Kang, Q., Wang, C., Zhou, S., Li, G., Lu, T., Tian, Y., He, P.: Low-temperature co-hydroxylated Cu/SiO2 hybrid bonding strategy for a memory-centric chip architecture. ACS Appl. Mater. Interfaces 13(32), 38866–38876 (2021). https://doi.org/10.1021/acsami.1c09796

Kang, Q., Li, G., Li, Z., Tian, Y., Wang, C.: Surface co-hydrophilization via ammonia inorganic strategy for low-temperature Cu/SiO2 hybrid bonding. J. Mater. Sci. Technol. 149, 161–166 (2023). https://doi.org/10.1016/j.jmst.2022.12.012

Shie, K.C., He, P.S., Kuo, Y.H., Ong, J.J., Tu, K.N., Lin, B.T.H., Chang, C.C., Chen, C.: Hybrid bonding of nanotwinned copper/organic dielectrics with low thermal budget. In: IEEE 71st ECTC, pp. 432–437 (2021). https://doi.org/10.1109/ECTC32696.2021.00079

Lee, K.W., Nakamura, T., Ono, T., Yamada, Y., Mizukusa, T., Hashimoto, H., Park, K.T., Kurino, H., Koyanagi, M.: Three-dimensional shared memory fabricated using wafer stacking technology. In: IEEE IEDM, pp. 165–167 (2000). https://doi.org/10.1109/IEDM.2000.904284

Koyanagi, M., Nakamura, T., Yamada, Y., Kikuchi, H., Fukushima, T., Tanaka, T., Kurino, H.: Three-dimensional integration technology based on wafer bonding with vertical buried interconnections. In: IEEE TED, pp. 2799–2808 (2006). https://doi.org/10.1109/TED.2006.884079

Kagawa, Y., Fujii, N., Aoyagi, K., Kobayashi, Y., Nishi, S., Todaka, N., Takeshita, S., Taura, J., Takahashi, H., Nishimura, Y., Tatani, K., Kawamura, M., Nakayama, H., Nagano, T., Ohno, K., Iwamoto, H., Kadomura, S., Hirayama, T.: Novel stacked CMOS image sensor with advanced Cu2Cu hybrid bonding. In: IEEE IEDM, pp. 8.4.1–8.4.4. (2016). https://doi.org/10.1109/IEDM.2016.7838375

Tsugawa, H., Takahashi, H., Nakamura, R., Umebayashi, T., Ogita, T., Okano, H., Iwase, K., Kawashima, H.: Pixel/DRAM/logic 3-layer stacked CMOS image sensor technology. In: IEEE IEDM, pp. 56–59 (2017). https://doi.org/10.1109/IEDM.2017.8268317

Chen, M.F., Lin, C.S., Liao, E.B., Chiou, W.C., Kuo, C.C., Hu, C.C., Tsai, C.H., Wang, C.T., Yu, D.: SoIC for low-temperature, multi-layer 3D memory integration. In: IEEE 70th ECTC, pp. 855–860 (2020). https://doi.org/10.1109/ECTC32862.2020.00139

Gao, G., Theil, J., Fountain, G., Workman, T., Guevara, G., Uzoh, C., Suwito, D., Lee, B., Bang, K.M., Katkar, R., Mirkarimi, L.: Die to wafer hybrid bonding: multi-die stacking with TSV integration. In: IEEE IWLPC (2020). https://doi.org/10.23919/IWLPC52010.2020.9375884

Kim, J., Seo, S.K., Kim, H., Kim, Y., Jo, C., Kim, D.W.: A study on bonding pad structure and layout for Fine pitch hybrid bonding. In: IEEE 72nd ECTC, pp. 712–715 (2022). https://doi.org/10.1109/ECTC51906.2022.00119

Varpula, A., Suni, T., Dekker, J.R.: Nondestructive characterization of fusion and plasma activated wafer bonding using mesa and recess structures. ECS J. Solid State Sci. Technol. 4(2), 42–52 (2015). https://doi.org/10.1149/2.0121502jss

Li, G., Kang, Q., Niu, F., Wang, C.: Recent progress on bumpless Cu/SiO2 hybrid bonding for 3D heterogeneous integration. Microelectron. Int. (2022). https://doi.org/10.1108/MI-07-2022-0121

Moreau, S., Jourdon, J., Lhostis, S., Bouchu, D., Ayoub, B., Arnaud, L., Frémont, H.: Review—hybrid bonding-based interconnects: a status on the last robustness and reliability achievements. ECS J. Solid State Sci. Technol. 11, 024001 (2022). https://doi.org/10.1149/2162-8777/ac4ffe

IEEE EPS, Heterogeneous Integration Roadmap (HIR): Chapter 22: Interconnects for 2D and 3D Architectures. Heterogeneous Integration Roadmap (2021)

Lee, E.L., Goh, Y.S., Haseeb, A.S.M.A., Wong, Y.H., Mohd Sabri, M.F., Low, B.Y.: Review—electrochemical migration in electronic materials: factors affecting the mechanism and recent strategies for inhibition. J. Electrochem. Soc. 170(2), 21505 (2023). https://doi.org/10.1149/1945-7111/acb61a

Chen, Y.H., Yang, C.A., Kuo, C.C., Chen, M.F., Tung, C.H., Chiou, W.C., Yu, D.: Ultra high density SoIC with sub-micron bond pitch. In: IEEE 70th ECTC, pp. 576–581 (2020). https://doi.org/10.1109/ECTC32862.2020.00096

Acknowledgements

This research was supported by the National R&D Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (no. 2022M3I7A4072293 and no. 2018M3A7B4089670) and partially supported by a Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0008458, HRD Program for Industrial Innovation).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, YG., McInerney, M., Joo, YC. et al. Copper Bonding Technology in Heterogeneous Integration. Electron. Mater. Lett. 20, 1–25 (2024). https://doi.org/10.1007/s13391-023-00433-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-023-00433-4