Abstract

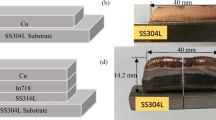

The integration of vertically stacked interconnects as promising technology with improved performance, reduced size, and low cost has been studied. Because of its performance and fine pitch pattern advantages, Cu is gaining importance over traditional solder materials. However, both the high bonding temperature requirement and the oxidation of Cu must be addressed. In this study, Cu bonding using a 12-nm Ti nanolayer as a metal passivation layer was studied as regards the effect of anti-oxidation of the Cu surface and solid diffusion between Ti and Cu. Ti rapidly oxidized upon exposure to air, and the diffusion of Ti and TiO2-x from the bonding interface to the Cu layer was observed, although some remained at the bonding interface. It was found that the diffusion of Cu into the Ti nanolayer was slower than the diffusion of Ti/TiO2-x into the Cu layer due to a higher activation energy. The bonding of Cu/Ti-Ti/Cu was performed at 200°C, and the average shear strength was 13.2 MPa.

Graphical Abstract

Similar content being viewed by others

References

K. Banerjee, S.J. Souri, P. Kapur, and K.C. Saraswat, 3-D ICs: A novel chip design for improving deep-submicrometer interconnect performance and systems-on-chip integration. Proc. IEEE 89, 602 (2001).

T. Li, J. Hou, J. Yan, R. Liu, H. Yang, and Z. Sun, Chiplet heterogeneous integration technology—status and challenges. Electronics 9, 670 (2020).

G. Parès, C. Karoui, A. Zaid, F. Dosseul, M. Feron, A. Attard, G. Klug, H. Luesebrink, K. Martinschitz, N. Launay, S. Belhenini, and G. Simon, Full integration of a 3D demonstrator with TSV first interposer, ultra thin die stacking and wafer level packaging. In: IEEE 63rd electronic components technology conference proceedings (2013), pp. 305–306

H. Park, and S.E. Kim, Two-step plasma treatment on copper surface for low-temperature Cu thermo-compression bonding. IEEE Trans. Comp. Packag. Manuf. Tech. 10, 332 (2019).

B. Wu, S. Zhang, F. Wang, and Z. Chen, Micro copper pillar interconnection using thermosonic flip chip bonding. J. Electron. Packag. 140, 044502 (2018).

S. Choudhary, J.V.N. Sarma, S. Pande, S. Ababou-Girard, P. Turban, N. Lepine, and S. Gangopadhyay, Oxidation mechanism of thin Cu films: a gateway towards the formation of single oxide phase. AIP Adv. 8, 055114 (2018).

S.L. Chua, J.M. Chan, S.C.K. Goh, and C.S. Tan, Cu–Cu bonding in ambient environment by Ar/N2 plasma surface activation and its characterization. IEEE Trans. Compon. Packag. Manuf. Tech. 9, 596 (2018).

H. Park, H. Seo, Y. Kim, S. Park, and S.E. Kim, Low-temperature (260° C) solderless Cu–Cu bonding for fine-pitch 3-D packaging and heterogeneous integration. IEEE Trans. Compon. Packag. Manuf. Tech. 11, 565 (2021).

S. Bonam, A.K. Panigrahi, C.H. Kumar, S.R.K. Vanjari, and S.G. Singh, Interface and reliability analysis of Au-passivated Cu–Cu fine-pitch thermocompression bonding for 3-D IC applications. IEEE Trans. Comp. Packag. Manuf. Tech. 9, 1227 (2019).

Y.P. Huang, Y.S. Chien, R.N. Tzeng, and K.N. Chen, Demonstration and electrical performance of Cu–Cu bonding at 150 °C With Pd passivation. IEEE Trans. Electron Dev. 62, 2587 (2015).

Y.P. Huang, Y.S. Chien, R.N. Tzeng, M.S. Shy, T.H. Lin, K.H. Chen, C.T. Chiu, J.C. Chiou, C.T. Chuang, W. Hwang, H.M. Tong, and K.N. Chen, Novel Cu-to-Cu bonding with Ti passivation at 180 in 3-D integration. IEEE Electron Dev. Lett. 34, 1551 (2013).

A. K. Panigrahi, S. Bonam, T. Ghosh, S. R. K. Vanjari, and S. G. Singh, High quality fine-pitch Cu-Cu Wafer-on-Wafer bonding with optimized Ti passivation at 160℃. In: IEEE 66th ECTC, 1791-1796 (2016)

A.K. Panigrahi, T. Ghosh, S.R.K. Vanjari, and S.G. Singh, Demonstration of sub 150 °C Cu-Cu thermocompression bonding for 3D IC applications, utilizing an ultra-thin layer of Manganin alloy as an effective surface passivation layer. Mater. Lett. 194, 86 (2017).

W. Yang, J. Zhou, X. Jiang, X. Ye, X. Xuan, C. Wu, and L. Luo, Cu-Cu low temperature bonding based on lead-free solder with graphene interlayer. Appl. Phys. Lett. 115, 122102 (2019).

S. Tsukimoto, T. Kabe, K. Ito, and M. Murakami, Effect of annealing ambient on the self-formation mechanism of diffusion barrier layers used in Cu(Ti) interconnects. J. Electron. Matter. 36, 258 (2007).

Y. Iijima, K. Hosono, and K. Hirano, Diffusion of titanium in copper. Metallurgical Trans. A 8A, 997 (1977).

A. Kuper, H. Letaw Jr., L. Slifkin, E. Sonder, and C.T. Tomizuka, Self-diffusion in copper. Phys. Rev. 96, 1224 (1954).

B.S. Bokstein, V.I. Vnukov, E.V. Golosov, M.I. Karpov, Y.R. Kolobov, D.A. Kolesnikov, V.P. Korzhov, and A.O. Rodin, Structure and diffusion processes in laminated composites of a Cu–Ti system. Russ. Phys. J. 52, 811 (2009).

K.Y. Lim, Y.S. Lee, Y.D. Chung, I.W. Lyo, C.N. Whang, J.Y. Won, and H.J. Kang, Grain boundary diffusion of Cu in TiN film by X-ray photoelectron spectroscopy. Appl. Phys. A 70, 431 (2000).

K.Y. Lim, Y.S. Lee, Y.D. Chung, K.M. Lee, C.N. Whang, B.S. Choi, J.Y. Won, and H.J. Kang, The study of Grain boundary diffusion effect in Tin/Cu by XPS. J. Kor. Vac. Soc. 7, 112–117 (1998).

K.C. Park, and K.B. Kim, Effect of annealing of titanium nitride on the diffusion barrier property in Cu metallization. J. Electrochem. Soc. 142, 3109 (1995).

Y.S. Lee, K.Y. Lim, Y.D. Chung, C.N. Whang, J.J. Woo, and Y.P. Lee, Method for the study of grain boundary diffusion effects by Auger electron spectroscopy sputter depth profiling. J. Vac. Sci. Tech. A 15, 204 (1997).

W.F. Gale, and T.C. Totemeir, Smithells metals reference book, 8th end (Oxford: Elsevier, Butterworth-Heinemann, 2003).

S. Park, Y. Kim, and S.E. Kim, Evaluation of 12nm Ti layer for low temperature Cu-Cu bonding. J. Microelectron. Packag. Soc. 28, 9 (2021). (in Korean).

K. C. H. Kumar, I. Ansara, P. Wollants, L. Delaey, and Z. Metallkd, “Thermodynamic optimisation of the Cu-Ti system”, 87, 666-672 (1996) (Database for FactSage http://www.rccm.co.jp/factsage/gedb/cu-elem/cuti/cuti.html) Accessed 09 December 2021

Acknowledgments

This research was partly supported by the Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0008458, HRD Program for Industrial Innovation) and Creative Materials Discovery Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (MRF-2019M3D1A2104109).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, S., Kim, Y. & Kim, S.E. Low-Temperature Diffusion Behavior of Ti in Cu/Ti-Ti/Cu Bonding. J. Electron. Mater. 51, 2617–2623 (2022). https://doi.org/10.1007/s11664-022-09501-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-022-09501-1