Abstract

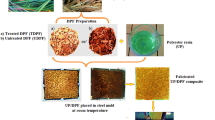

This study introduces the usage of date palm fibers (DPFs) as reinforcement of geopolymer matrices. The DPFs were subjected to alkaline treatment by immersion in alkaline solution (5 M) for 24 h at 40 °C. Because of the subsequent strong alkaline geopolymerization, the natural resin (lignin) was removed and the DPFs with a diameter around 600 µm on average broke down into microfibrils with an average diameter of 50 µm. The resultant microfibrils with a large surface area form a strong fiber-matrix adhesion force, thus leading to improved mechanical performance of the composite. The DPF-reinforced geopolymer composite (DPCs) are studied by examining their ductility, high elongation, and strain hardening with a modulus of 200 MPa. The experimental results indicate better mechanical properties of geopolymer composites when compared to the reference geopolymers. The flexural strength of the DPF-geopolymer composite is 12.5 MPa, more than four times the strength of reference geopolymers. The contribution of this research lies in developing attractive green composites based on DPFs and kaolinite. Reinforcement of the geopolymers with natural, abundant, recyclable, and reusable DPFs not only helps improve the mechanical performance of the composites, it also reduces CO2 emission from burning them. The novelty of this study is that microfibrils are extracted from the DPFs during the alkali geopolymerization reactions. These microfibrils are characterized by high surface areas, and subsequently high adhesion forces with the geopolymer matrix.

Similar content being viewed by others

References

Komnitsas, K.; Zaharaki, D.; Perdikatsis, V.: Effect of synthesis parameters on the compressive strength of low-calcium ferronickel slag inorganic polymers. J. Hazard. Mater. 161, 760–768 (2009). https://doi.org/10.1016/j.jhazmat.2008.04.055

Komnitsas, K.; Zaharaki, D.; Perdikatsis, V.: Geopolymerisation of low calcium ferronickel slags. J. Mater. Sci. 9(42), 3073–3082 (2007). https://doi.org/10.1007/s10853-006-0529-2

Alshaaer, M.: Two-phase geopolymerization of kaolinite-based geopolymers. Appl Clay Sci. 86, 162–168 (2013). https://doi.org/10.1016/j.clay.2013.10.004

Alshaaer, M.; Cuypers, H.; Wastiels, J. Stabilisation of kaolinitic soil for construction purposes by using mineral polymerisation technique. In Proceedings of the 6th International Conference Technology for Developing Countries, Amman (2002).

Yousef, R.; El-Eswed, B.; Alshaaer, M.; Khalili, F.; Rahier, H.: Degree of reactivity of two kaolinitic minerals in alkali solution using zeolitic tuff or silica sand filler. Ceram. Int. 38(6), 5061–5067 (2012)

Alshaaer, M.; El-Eswed, B.; Yousef, R.I.; Khalili, F.; Rahier, H.: Development of functional geopolymers for water purification, and construction purposes. J. Saudi Chem. Soc. 20(1), S85–S92 (2012)

Hajjaji, W.; Andrejkovičová, S.; Zanelli, C.; Alshaaer, M.; Dondi, D.; Labrincha, J.; Rocha, F.: Composition and technological properties of geopolymers based on metakaolin and red mud. Mater. Des. 52, 648–654 (2013)

Hamaideh, A.; Komnitsas, K.; Esaifan, M.; Al-Kafawein, J.; Rahier, H.; Alshaaer, M.: Advantages of applying a steam curing cycle for the production of kaolinite-based geopolymers. Arab. J. Sci. Eng. 39(11), 7591–7597 (2014)

Marvila, M.T.; de Azevedo, A.R.G.; Vieira, C.M.F.: Reaction mechanisms of alkali-activated materials. Revista IBRACON de Estruturas e Materiais. (2021). https://doi.org/10.1590/S1983-41952021000300009

Marvila, A.A.; Oliveira, M.; Ferreira, L.; Colorado, W.; Teixeira, H.; Vieira, S.; Maurício, C.: Circular economy and durability in geopolymer ceramics pieces obtained from glass polishing waste. Int. J. Appl. Ceram. Technol. (2021). https://doi.org/10.1111/IJAC.13780

El-Eswed, B.; Yousef, R.; Alshaaer, M.; Khalili, F.; Khoury, H.: Alkali solid-state conversion of kaolin and zeolite to effective adsorbents for removal of lead from aqueous solution. Desalin. Water Treat. 8(1–3), 124–130 (2009)

Alshaaer, M.; El-Eswed, B.; Yousef, R.I.; Khalili, F.; Khoury, H.: Low-cost solid geopolymeric material for water purification. Ceram. Trans. 207, 265–271 (2009)

Hamaideh, A.; Al-Qarallah, B.; Hamdi, M.R.; Abu Mallouh, S.; Alshaaer, M.: Synthesis of geopolymers using local resources for construction and water purification. J. Water Resour. Prot. 6, 507–513 (2014). https://doi.org/10.4236/jwarp.2014.65049

Alshaaer, M.; Abu Mallouh, S.; Al-Kafawein, J.; Al-Faiyz, Y.; Fahmy, T.; Kallel, A.; Rocha, F.: Fabrication, microstructural and mechanical characterization of Luffa cylindrical fibre—reinforced geopolymer composite. Appl. Clay Sci. 143, 125–133 (2017)

Agrela, F; Cabrera, M; Morales, M. M.; Zamorano M.; Alshaaer, M. Biomass fly ash and biomass bottom ash; in New trends in eco-efficient and recycled concrete, Woodhead Publishing, pp 23–58 (2019).

Alshaaer, M.; J Al-Fayez, Y.; Fahmy T.; Hamaideh, A. “Synthesis of geopolymer cement using natural resources for green construction materials,” in Recent Advances in Earth Sciences, Environment and Development. Proceedings of the 8th International Conference on Engineering Mechanics, Structures, Engineering Geology (EMESEG'15), Konya, 2015.

El-Eswed, B.; Yousef, R.I.; Alshaaer, M.; Hamadneh, I.; Al-Gharabli, S.; Khalili, F.: Stabilization/solidification of heavy metals in kaolin/zeolite based geopolymers. Int. J. Miner. Process. 137, 34–42 (2015)

Alshaaer, M.; Shqair, M.; Abdelwahed, H.G.; Abuhasel, K.; Toro, M.Z.: Stabilization of heavy oil fly ash (HFO) for construction and environmental purposes. Int J. Appl. Eng. Res. 12(4), 488–497 (2017)

Alshaaer, M.; Fahmy, F.; Shqair, M.; Al-Kafawein, J.: Production of heavy fuel oil fly ash (HFO)-based geopolymers for passive cooling systems. Int. J. Appl. Eng. Res. 13(1), 134–140 (2018)

Zhao, Q.; Nair, B.; Rahimian, T.; Balaguru, P.: Novel geopolymer based composites with enhanced ductility”. J. Mater. Sci. 42(9), 3131–3137 (2007)

Natali, A.; Manzi, S.; Bignozzi, M.: Novel fiber-reinforced composite materials based on sustainable geopolymer matrix. Proc. Eng. 21, 1124–1131 (2011)

Puertas, F.; Amat, T.; Fernández-Jiménez, A.; Vázquez, T.: Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 33(12), 2031–2036 (2003)

Alshaaer, M.; Zaharaki, D.; Komnitsas, K.: Microstructural characteristics and adsorption potential of a zeolitic tuff–metakaolin geopolymer. Desalin. Water Treat. 56(2), 338–345 (2014). https://doi.org/10.1080/19443994.2014.938306

Marvila, M.T.; de Azevedo, A.R.G.; Delaqua, G.C.G.; Mendes, B.; Pedroti, L.G.; Vieira, C.M.F.: Performance of geopolymer tiles in high temperature and saturation conditions. Constr Build Mater. (2021). https://doi.org/10.1016/j.conbuildmat.2021.122994

Sun, P.; Wu, H.: Transition from brittle to ductile behavior of fly ash using PVA fibers. Cem Concr Compos. 30(1), 29–36 (2008)

Alshaaer, M.: Synthesis, characterization, and recyclability of a functional jute-based geopolymer composite. Front. Built Environ. 7, 631307 (2021)

Li, W.; Xu, J.: Impact characterization of basalt fiber reinforced geopolymeric concrete using a 100-mm-diameter split Hopkinson pressure bar. Mater. Sci. Eng. A. 514, 145–153 (2009). https://doi.org/10.1016/j.msea.2009.02.033

Correia, E.; Torres, S.; Alexandre, M.; Gomes, K.; Barbosa, N.; Barros, S.: Mechanical performance of natural fibers reinforced geopolymer composites. Mater. Sci. Technol. 758, 139–145 (2013)

Korniejenko, K.; Fraczek, E.; Pytlak, E.; Adamski, M.: Mechanical properties of geopolymer composites reinforced with natural fibers. Proc. Eng. 151, 388–393 (2016)

Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—a review of potential eco-friendly applications to the construction industry. SM&T, 23, 2020.

Niaki, S.R.A.; Kharrat, F.G.Z.: Effect of fiber chemical treatments on performance of date palm fibers using response surface methodology. Environ. Prog. Sustain. Ener. 38(5), 13177 (2019)

Al-Oqla, F.; Sapuan, S.: Natural fiber reinforced polymer composites in industrial applications: feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 66, 347–354 (2014)

Luo, Z.; Li, P.; Cai, D.; Chen, Q.; Qin, P.; Tan, T.; Cao, H.: Comparison of performances of corn fiber plastic composites made from different parts of corn stalk. Ind. Crops Prod. 95, 521–527 (2017)

Ou, R.; Xie, Y.; Wolcott, M.; Sui, S.; Wang, Q.: Morphology, mechanical properties, and dimensional stability of wood particle/high density polyethylene composites: effect of removal of wood cell wall composition. Mater. Des. 58, 339–345 (2014)

Oushabi, A.; Sair, S.; Abboud, Y.; Tanane, O.; Bouari, E.: Natural thermal-insulation materials composed of renewable resources: characterization of local date palm fibers (LDPF). J. Mater. Environ. Sci. 6(12), 3395–3402 (2015)

Wong, K.; Yousif, B.; Low, K.: The effects of alkali treatment on the interfacial adhesion of bamboo fibres. Proc. Inst. Mech. Eng. L. J. Mater. Des. Appl. 224(3), 139–148 (2010)

Alshaaer, M.: Synthesis and characterization of self-healing geopolymer composite. Constr Build Mater. 245, 118432 (2020). https://doi.org/10.1016/j.conbuildmat.2020.118432

Valadez-Gonzalez, A.; Cervantes-Uc, J.; Olayo, R.; Herrera-Franco, P.: Effect of fiber surface treatment on the fiber-matrix bond strength of natural fiber reinforced composites. Compos. Part B-Eng. 30(3), 309–320 (1999)

Li, M.; Zhou, S.; Guo, X.: Effects of alkali-treated bamboo fibers on the morphology and mechanical properties of oil well cement. Constr Build Mater. 150, 619–625 (2017)

Rao, K.M.M.; Rao, K.M.: Extraction and tensile properties of natural fibers: Vakka, date and bamboo. Compos. Struct. 77, 288–295 (2007). https://doi.org/10.1016/j.compstruct.2005.07.023

Ranjbar, N.; Zhang, M.: Fiber reinforced geopolymer composites: A review. Cem. Concr. Compos. 107, 103498 (2019). https://doi.org/10.1016/j.cemconcomp.2019.103498

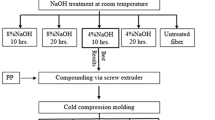

Al-Otaibi, M.; Alothman, O.; Alrashed, M.; Anis, A.; Naveen, J.; Jawaid, M.: Characterization of date palm fiber-reinforced different polypropylene matrices. Polym. 12(3), 597 (2020)

Abu-Sharkh, B.; Kahraman, R.; Abbasi, S.; Hussein, I.: Effect of epolene E-43 as a compatibilizer on the mechanical properties of palm fiber–poly (propylene) composites. J. Appl. Polym. Sci. 92, 2581–2592 (2004)

ASTM D790–10, Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. ASTM International, West Conshohocken, PA, 2010, www.astm.org doi: https://doi.org/10.1520/D0790-10

Gibson, L.J.: The hierarchical structure and mechanics of plant materials: review. J. R. Soc. Interface 9, 2749–2766 (2012). https://doi.org/10.1098/rsif.2012.0341

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alshaaer, M., Alqahtani, O., Alharbi, M.M.S. et al. Synthesis and Characterization of Date Palm Fiber-Reinforced Geopolymer Composite. Arab J Sci Eng 47, 12323–12332 (2022). https://doi.org/10.1007/s13369-021-06378-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06378-w