Abstract

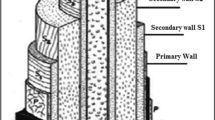

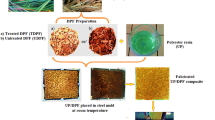

Sustainable bio-materials are now potential alternatives for synthetic composites to achieve more functional green products. However, the microstructure-performance synergy is critical in such materials. In this work, the mechanical properties, thermal stability, and morphological analysis of the date palm polypropylene composites are investigated. Various reinforcement conditions, chemical treatments, surface topology, thermogravimetric analysis, and its derivative were utilized to explore the relation of the microstructure with the composite performance. Date palm leaflets (DPLs) were treated with sodium hydroxide at various conditions to determine the optimal samples. Morphological analysis was also performed. Results reveal that this treatment improves the tensile strength and modulus of the composites. Moreover, DPL fibers have positive impacts on both tensile and flexural modulus. At 30 wt% of DPL fibers, the fibers scored the highest values. Both TGA and DTG analyses show that DPL fibers can withstand a temperature up to 227 °C. Also, TG-DTG thermograms show that the addition of DPL fibers has enhanced the thermal stability of polypropylene composites. Scanning electron microscope enhanced our understanding of the composite performance trends towards assessing their capabilities for more reliable implementations of more sustainable green products.

Similar content being viewed by others

References

Agarwal J, Mohanty S, Nayak SK (2021) Influence of cellulose nanocrystal sisal fiber on the mechanical, thermal, and morphological performance of polypropylene hybrid composites. Polym Bull 78:1609–1635

Ahmad Saffian H, Talib MA, Lee SH, Md Tahir P, Lee CH, Ariffin H, Asa’ari AZM (2020) Mechanical strength, thermal conductivity and electrical breakdown of kenaf Core fiber/lignin/polypropylene biocomposite. Polymers 12:1833

Alarifi IM (2021) Investigation into the morphological and mechanical properties of date palm fiber-reinforced epoxy structural composites. J Vinyl Addit Technol 27:77–88

Ali ME, Alabdulkarem A, Materials B (2017) On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Construction 138:276–284

AL-Oqla FM (2021a) Performance trends and deteriorations of lignocellulosic grape fiber/polyethylene biocomposites under harsh environment for enhanced sustainable bio-materials. Cellulose 28:2203–2213

AL-Oqla FM (2021b) Predictions of the mechanical performance of leaf fiber thermoplastic composites by FEA. Int J Appl Mech. https://doi.org/10.1142/S1758825121500666

AL-Oqla FM (2021c) Effects of intrinsic mechanical characteristics of lignocellulosic fibres on the energy absorption and impact rupture stress of low density polyethylene biocomposites. Int J Sustain Eng 14:2009–2017

AL-Oqla FM, Sapuan SM (2014) Natural fiber reinforced polymer composites in industrial applications: feasibility of date palm fibers for sustainable automotive industry. J Cleaner Prod 66:347–354. https://doi.org/10.1016/j.jclepro.2013.10.050

AL-Oqla FM, Sapuan SM, Fares O (2018) Electrical–based applications of natural fiber vinyl polymer composites. In: Natural fibre reinforced vinyl ester and vinyl polymer composites. Elsevier, pp 349–367

AL-Oqla FM, Hayajneh MT, Fares O (2019) Investigating the mechanical thermal and polymer interfacial characteristics of Jordanian lignocellulosic fibers to demonstrate their capabilities for sustainable green materials. J Clean Prod 241:118256

AL-Oqla FM, Hayajneh MT, Aldhirat A (2021b) Tribological and mechanical fracture performance of Mediterranean lignocellulosic fiber reinforced polypropylene composites. Polym Compos 42:5501–5511

Al-Otaibi MS, Alothman OY, Alrashed MM, Anis A, Naveen J, Jawaid M (2020) Characterization of date palm fiber-reinforced different polypropylene matrices. Polymers 12:597

Alothman OY, Shaikh HM, Alshammari BA, Jawaid M (2021) Structural, morphological and thermal properties of nano filler produced from date palm-based micro fibers (Phoenix Dactylifera L.). J Polym Environ 30:1–9

Alsaeed T, Yousif B, Ku H (2013a) The potential of using date palm fibres as reinforcement for polymeric composites. Mater Des 43:177–184

AlZebdeh K, Nassar M, Al-Hadhrami M, Al-Aamri O, Al-Defaai S, Al-Shuaily S (2017) Characterization of mechanical properties of aligned date palm frond fiber-reinforced low density polyethylene. J Eng Res 14:115–123

Asim M, Jawaid M, Khan A, Asiri AM, Malik MA (2020) Effects of date palm fibres loading on mechanical, and thermal properties of date palm reinforced phenolic composites. J Mater Res Technol 9:3614–3621

Asim M, Jawaid M, Fouad H, Alothman O (2021) Effect of surface modified date palm fibre loading on mechanical, thermal properties of date palm reinforced phenolic composites. Compos Struct 267:113913

Asumani O, Reid R, Paskaramoorthy R (2012) The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos Part A Appl Sci Manuf 43:1431–1440

Asyraf M et al (2021a) Recent advances of thermal properties of sugar palm lignocellulosic fibre reinforced polymer composites. Int J Biol Macromol 193:1587–1599

Asyraf M, Rafidah M, Azrina A, Razman M (2021b) Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: a comprehensive review on chemical treatments. Cellulose 28:1–21

Ates B, Koytepe S, Ulu A, Gurses C, Thakur VK (2020) Chemistry, structures, and advanced applications of nanocomposites from biorenewable resources. Chem Rev 120:9304–9362

Azeredo HM, Mattoso LHC, Wood D, Williams TG, Avena-Bustillos RJ, McHugh TH (2009) Nanocomposite edible films from mango puree reinforced with cellulose nanofibers. J Food Sci 74:N31–N35

Azman M et al (2021) Natural fiber reinforced composite material for product design: a short review. Polymers 13:1917

Belgacem C, Tarres Q, Espinach FX, Mutjé P, Boufi S, Delgado-Aguilar M (2020) High-yield Lignocellulosic fibers from date palm biomass as reinforcement in polypropylene composites: effect of fiber treatment on composite properties. Polymers 12:1423

Biswal M, Mohanty S, Nayak SK (2012) Thermal stability and flammability of banana-fiber-reinforced polypropylene nanocomposites. J Appl Polym Sci 125:E432–E443

Chihaoui B, Serra-Parareda F, Tarrés Q, Espinach FX, Boufi S, Delgado-Aguilar M (2020) Effect of the fiber treatment on the stiffness of date palm fiber reinforced PP composites: macro and micromechanical evaluation of the young’s modulus. Polymers 12:1693

Correa-Aguirre JP, Luna-Vera F, Caicedo C, Vera-Mondragón B, Hidalgo-Salazar MA (2020) The effects of reprocessing and fiber treatments on the properties of polypropylene-sugarcane bagasse biocomposites. Polymers 12:1440

Dehghani A, Ardekani SM, Al-Maadeed MA, Hassan A, Wahit MU, Design, (2013) Mechanical and thermal properties of date palm leaf fiber reinforced recycled poly (ethylene terephthalate) composites. Materials 52:841–848

El-Juhany LI (2010) Degradation of date palm trees and date production in Arab countries: causes and potential rehabilitation. Aust J Basic Appl Sci 4:3998–4010

Fares O, AL-Oqla FM, Hayajneh MT (2019) Dielectric relaxation of Mediterranean lignocellulosic fibers for sustainable functional biomaterials. Mater Chem Phys 229:174–182

Gheith MH, Aziz MA, Ghori W, Saba N, Asim M, Jawaid M, Alothman OY (2019) Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J Mater Res Technol 8:853–860

Ghori W, Saba N, Jawaid M, Asim M (2018) A review on date palm (phoenix dactylifera) fibers and its polymer composites. In: IOP conference series: materials science and engineering, IOP Publishing, 1: 012009

Hayajneh MT, AL-Oqla FM, Mu’ayyad M (2021) Hybrid green organic/inorganic filler polypropylene composites: Morphological study and mechanical performance investigations. e-Polymers 21:710–721

Jang Y-C, Lee G, Kwon Y, Lim J-h, Jeong J-h (2020) Recycling and management practices of plastic packaging waste towards a circular economy in South Korea resources. Conserv Recycl 158:104798

Karan H, Funk C, Grabert M, Oey M, Hankamer B (2019) Green bioplastics as part of a circular bioeconomy. Trends Plant Sci 24:237–249

Liu Y, Ma Y, Yu J, Zhuang J, Wu S, Tong J (2019) Development and characterization of alkali treated abaca fiber reinforced friction composites. Compos Interfaces 26:67–82

Mahmoudi N (2013) Use of date palm fibers as reinforcement for thermoplastic-based composites. Mech Ind 14:71–77

Muthalagu R, Murugesan J, Kumar SS, Babu BS (2021) Tensile attributes and material analysis of kevlar and date palm fibers reinforced epoxy composites for automotive bumper applications. Mater Today Proc 46:433–438

Nagaraj N, Balasubramaniam S, Venkataraman V, Manickam R, Nagarajan R, Oluwarotimi IS (2020) Effect of cellulosic filler loading on mechanical and thermal properties of date palm seed/vinyl ester composites. Int J Biol Macromol 147:53–66

Nurazzi N et al (2021) Thermogravimetric analysis properties of cellulosic natural fiber polymer composites: a review on influence of chemical treatments. Polymers 13:2710

Oktaee J, Lautenschläger T, Günther M, Neinhuis C, Wagenführ A, Lindner M, Winkler A (2017) Characterization of willow bast fibers (Salix spp.) from short-rotation plantation as potential reinforcement for polymer composites. BioResources 12:4270–4282

Rodriguez V, Sukumaran J, Schlarb A, De Baets P (2016) Reciprocating sliding wear behaviour of PEEK-based hybrid composites. Wear 362:161–169

Saba N, Alothman OY, Almutairi Z, Jawaid M, Ghori W (2019) Date palm reinforced epoxy composites: tensile, impact and morphological properties. J Mater Res Technol 8:3959–3969

Samal SK, Mohanty S, Nayak SK (2009) Banana/glass fiber-reinforced polypropylene hybrid composites: fabrication and performance evaluation. Polym-Plast Technol Eng 48:397–414

Thakur V, Singha A, Thakur M (2012) Green composites from natural fibers: mechanical and chemical aging properties. Int J Polym Anal Charact 17:401–407

Thakur V, Singha A, Thakur M (2013) Fabrication and physico-chemical properties of high-performance pine needles/green polymer composites. Int J Polym Mater Polym Biomater 62:226–230

Tripathy S, Dehury J, Mishra D (2016) A study on the effect of surface treatment on the physical and mechanical properties of date-palm stem liber embedded epoxy composites. In: IOP conference series: materials science and engineering, IOP Publishing, 1: 012036

Yaghoobi H, Fereidoon A (2019) Thermal analysis, statistical predicting, and optimization of the flexural properties of natural fiber biocomposites using Box-Behnken experimental design. J Nat Fibers 16:987–1005

Yew BS, Muhamad M, Mohamed SB, Wee FH (2019) Effect of alkaline treatment on structural characterisation, thermal degradation and water absorption ability of coir fibre polymer composites. Sain Malays 48:653–659

Zanini NC, Barbosa RF, de Souza AG, Rosa DS, Mulinari DR (2021) Revaluation of Australian palm residues in polypropylene composites: statistical influence of fiber treatment. J Compos Mater 55:813–826

Acknowledgments

This work was supported by a grant from the Deanship of Scientific Research at the Jordan University of Science and Technology (JUST) with grant no. 448/2019.

Funding

This work was supported by a grant from the Deanship of Scientific Research at the Jordan University of Science and Technology (JUST) with grant no. 448/2019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

AL-Oqla, F.M., Hayajneh, M.T. & Al-Shrida, M.M. Mechanical performance, thermal stability and morphological analysis of date palm fiber reinforced polypropylene composites toward functional bio-products. Cellulose 29, 3293–3309 (2022). https://doi.org/10.1007/s10570-022-04498-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04498-6