Abstract

Hollow glass microspheres (HGMs), as a reinforcing material to prepare lightweight high-performance composites, have excellent mechanical properties. However, the composites prepared by simply mixing hollow glass microspheres with polymer resin have poor performance. In this study, compound coupling agent-modified HGM/EP composites were prepared by casting process with two silane coupling agents as compound coupling agents. Scanning electron microscopy and infrared (IR) spectroscopy were used to characterize the treated HGM. Meanwhile density, water absorption behavior, and mechanical properties of the modified HGM-filled epoxy composites were examined. It is found that the compound coupling agent could effectively improve the interfacial bonding between HGM and the matrix resin. A new chemical bond was formed between HGM and EP, which was confirmed by IR spectroscopy. Compared with their untreated counterparts, the composites treated with the complex coupling agent exhibited excellent mechanical properties, along with lower density and lower water absorption.

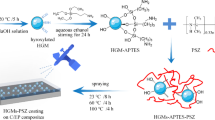

Graphical abstract

The composites prepared by treating hollow glass microspheres with mixed coupling agents showed improved properties in all the cases. The mechanical properties of the composites prepared using No. HGM-1 reached the maximum with tensile strength of 36.38 MPa, tensile modulus of 2.383 GPa, flexural strength of 49.82 MPa, flexural modulus of 1.558 GPa, and compressive strength of 98.14 MPa. Our strategy opens a new way to fabricate composites with enhanced mechanical performances.

Similar content being viewed by others

References

M. Abdelmouleh, S. Boufi, M. Belgacem, A. Dufresne, Short natural-fibre reinforced polyethylene and natural rubber composites: effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 67(7–8), 1627–1639 (2007)

S. Anirudh, C.G. Jayalakshmi, A. Anand, B. Kandasubramanian, S.O. Ismail, Epoxy/hollow glass microsphere syntactic foams for structural and functional application—a review. Eur. Polym. J. 171, 111163 (2022)

H.K. Bas, W. Jin, N. Gupta. Chemical stability of hollow glass microspheres in cementitious syntactic foams. Cem. Concr. Compos. 118, 103928 (2021)

J.K. Carson, Thermal diffusivity and thermal conductivity of dispersed glass sphere composites over a range of volume fractions. Int. J. Thermophys. 39, 1–11 (2018)

K.R. Dando, D.R. Salem, The effect of nano-additive reinforcements on thermoplastic microballoon epoxy syntactic foam mechanical properties. J. Compos. Mater. 52(7), 971–980 (2017)

X. Dong, M. Wang, X. Tao, J. Liu, A. Guo, Properties of heat resistant hollow glass microsphere/phosphate buoyancy materials with different coatings. Ceram. Int. 46(1), 415–420 (2020)

N. Gupta, R. Nagorny, Tensile properties of glass microballoon-epoxy resin syntactic foams. J. Appl. Polym. Sci. 102(2), 1254–1261 (2006)

N. Gupta, R. Ye, M. Porfiri, Comparison of tensile and compressive characteristics of vinyl ester/glass microballoon syntactic foams. Compos. B Eng. 41(3), 236–245 (2010)

R. Huang, P. Li, Elastic behaviour and failure mechanism in epoxy syntactic foams: the effect of glass microballoon volume fractions. Compos. B Eng. 78, 401–408 (2015)

E. Zegeye, A.K. Ghamsari, E. Woldesenbet, Mechanical properties of graphene platelets reinforced syntactic foams. Compos. B Eng. 60, 268–273 (2014)

R. Ciardiello, L.T. Drzal, G. Belingardi, Effects of carbon black and graphene nano-platelet fillers on the mechanical properties of syntactic foam. Compos. Struct. 178, 9–19 (2017)

C. Huang, Z. Huang, X. Lv, G. Zhang, Q. Wang, B. Wang, Surface modification of hollow glass microsphere with different coupling agents for potential applications in phenolic syntactic foams. J. Appl. Polym. Sci. 134(4) (2017)

P. Niazi, M. Javanbakht, M. Karevan, M.R. Tavakoli, Experimental and computational study of the thermal conductivity of polymeric micro spheres/polyester thermal insulating coatings. Polym. Bull. 80(4), 4387–4406 (2023)

Z. Yousaf, M. Smith, P. Potluri, W. Parnell, Compression properties of polymeric syntactic foam composites under cyclic loading. Compos. Part B Eng. 186, 107764 (2020)

Y. Zhou, Y. Wang, M. Fan, Incorporation of tyre rubber into wood plastic composites to develop novel multifunctional composites: interface and bonding mechanisms. Ind. Crops Prod. 141, 111788 (2019)

N. Gupta, S.E. Zeltmann, V.C. Shunmugasamy, D. Pinisetty, Applications of polymer matrix syntactic foams. Jom. 66(2), 245–254 (2013)

B. Yalcin, S.E. Amos, A.S. D’Souza, C.M. Clemons, I.S. Gunes, T.K. Ista, Improvements in processing characteristics and engineering properties of wood flour-filled high density polyethylene composite sheeting in the presence of hollow glass microspheres. J. Plast. Film Sheet. 28(2), 165–180 (2012)

M. Imran, A. Rahaman, S. Pal, Morphology and mechanical characterization of carbon nanotubes/epoxy based material filled with hollow glass microsphere. Mater. Res. Express. 7(2), 025307 (2020)

R.L. Poveda, N. Gupta, Carbon-nanofiber-reinforced syntactic foams: compressive properties and strain rate sensitivity. JOM 66(1), 66–77 (2013)

K. Shahapurkar, M. Doddamani, G.C. Mohan Kumar, N. Gupta, Effect of cenosphere filler surface treatment on the erosion behavior of epoxy matrix syntactic foams. Polym. Compos. 40(6), 2109–2118 (2018)

Y. Ma, Y. Zhou, Y. Sun, H. Chen, Z. Xiong, X. Li et al., Tunable magnetic properties of Fe3O4/rGO/PANI nanocomposites for enhancing microwave absorption performance. J. Alloy. Compd. 796, 120–130 (2019)

D. Lu, Q. Gao, X. Wu, Y. Fan, ZnO nanostructures decorated hollow glass microspheres as near infrared reflective pigment. Ceram. Int. 43(12), 9164–9170 (2017)

J. Yuan, Z. An, J. Zhang, Effects of hollow microsphere surface property on the mechanical performance of high strength syntactic foams. Compos. Sci. Technol. 199, 108309 (2020)

M. Doddamani, Effect of surface treatment on quasi-static compression and dynamic mechanical analysis of syntactic foams. Compos. B Eng. 165, 365–378 (2019)

R. Li, P. Wang, P. Zhang, G. Fan, G. Wang, X. Ouyang et al., Surface modification of hollow glass microsphere and its marine-adaptive composites with epoxy resin. Adv. Compos. Lett. 29, 1–8 (2020)

H. Yang, Y. Jiang, H. Liu, D. Xie, C. Wan, H. Pan et al., Mechanical, thermal and fire performance of an inorganic-organic insulation material composed of hollow glass microspheres and phenolic resin. J. Colloid Interface Sci. 530, 163–170 (2018)

C. Zhao, S. Diao, Y. Yuan, M. Wang, Preparation and properties of hollow glass microsphere/silicone rubber composite material with the transition layer of silicone resin. SILICON 13(2), 517–522 (2020)

R. Li, G. Fan, P. Wang, X. Ouyang, N. Ma, H. Wei, Effects of silane coupling agent modifications of hollow glass microspheres on syntactic foams with epoxy matrix. Polym. Polym. Compos. 29(9 suppl), S1191–S1203 (2021)

M. Jiang, Y. Xiong, B. Xue, Q. Zhang, Q. Wan, H. Zhao, Multi-layer graphene oxide synergistically modified by two coupling agents and its application in reinforced natural rubber composites. RSC Adv. 8(52), 29847–29854 (2018)

Y. Hou, M. Gao, R. An et al., Surface modification of oriented glass fibers for improving the mechanical properties and flame retardancy of polyamide 12 composites printed by powder bed fusion. Addit. Manuf. 62, 103195 (2023)

J. Chen, L. Zhao, K. Zhou, Improvement in the mechanical performance of multi jet fusion–printed aramid fiber/polyamide 12 composites by fiber surface modification. Addit. Manuf. 51, 102576 (2022)

C. Deng, J. Weng, K. Duan et al., Preparation and mechanical property of poly (ε-caprolactone)–matrix composites containing nano-apatite fillers modified by silane coupling agents. J. Mater. Sci. Mater. Med. 21, 3059–3064 (2010)

Z. Zhu, J. Wang, Y. Liu et al., Effect of hollow glass microspheres with different contents and types on properties of polypropylene composites. ChemistrySelect 7(48), e202202963 (2022)

C. Lu, H. Shao, N. Chen et al., Surface modification of polyimide fibers for high-performance composite by using oxygen plasma and silane coupling agent treatment. Text. Res. J. 92(23–24), 4899–4911 (2022)

Y. Guo, Z. Zhang, Z. Cao, D. Wang, Wear behavior of hollow glass beads (HGB) reinforced nitrile butadiene rubber: effects of silane coupling agent and filler content. Mater. Today Commun. 19, 366–373 (2019)

R.K. Goyal, A.S. Kapadia, Study on phenyltrimethoxysilane treated nano-silica filled high performance poly(etheretherketone) nanocomposites. Compos. B Eng. 50, 135–143 (2013)

J. Sang, S. Aisawa, K. Miura, H. Hirahara, O. Jan, P. Jozef et al., Adhesion of carbon steel and natural rubber by functionalized silane coupling agents. Int. J. Adhes. Adhes. 72, 70–74 (2017)

S.Y. Lee, J.S. Kim, S.H. Lim, S.H. Jang, D.H. Kim, N.H. Park et al., The investigation of the silica-reinforced rubber polymers with the methoxy type silane coupling agents. Polymers (Basel) 12(12), 3058 (2020)

X. Wang, C. Zhang, Q. Wu, H. Zhu, Y. Liu, Thermal properties of metakaolin-based geopolymer modified by the silane coupling agent. Mater. Chem. Phys. 267, 124655 (2021)

K. Yung, B. Zhu, T. Yue, C. Xie, Preparation and properties of hollow glass microsphere-filled epoxy-matrix composites. Compos. Sci. Technol. 69(2), 260–264 (2009)

Y. Min, Y. Fang, X. Huang, Y. Zhu, W. Li, J. Yuan et al., Surface modification of basalt with silane coupling agent on asphalt mixture moisture damage. Appl. Surf. Sci. 346, 497–502 (2015)

H. Nakatani, K. Iwakura, K. Miyazaki, N. Okazaki, M. Terano, Effect of chemical structure of silane coupling agent on interface adhesion properties of syndiotactic polypropylene/cellulose composite. J. Appl. Polym. Sci. 119(3), 1732–1741 (2011)

S. Shokoohi, A. Arefazar, R. Khosrokhavar, Silane coupling agents in polymer-based reinforced composites: a review. J. Reinf. Plast. Compos. 27(5), 473–485 (2008)

Acknowledgements

The authors gratefully acknowledge the financial support from the Foundation of State Key Laboratory of High-efficiency Utilization of Coal and Green Chemical Engineering (Grant no. 2021-K19), the Opening Project of State Key Laboratory of High Performance Ceramics and Superfine Microstructure (Grant no. SKL202003SIC), the Key Technologies R&D Program of Anhui Province of China (Grant no. 202104a05020033). Acknowledge is also to the support of General Projects of Shenzhen Stable Development (SZWD2021003) and Guangdong Basic and Applied Basic Research Foundation (2020B1515120002), the University Engineering Research Center of Crystal Growth and Applications of Guangdong Province (2020GCZX005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, Z., Liu, Y., Xian, G. et al. Effect of compound coupling agent treatment on mechanical property and water absorption of hollow glass microspheres/epoxy composite. Macromol. Res. 31, 771–779 (2023). https://doi.org/10.1007/s13233-023-00160-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-023-00160-7