Abstract

The potential use of PVA-mixed-valent tunnel structured manganese oxide nano-composite in the removal of multi-contaminants form aqueous solutions was assessed by studying the continuous simultaneous removal of lead, caesium, and cobalt. Within this context, the morphology and the nature of nanoparticle inclusion into the PVA matrix was assessed using SEM–EDX analysis. The nanoparticles are homogenously distributed in the polymeric matrix with some agglomerated inclusions of these particles. The thermal and chemical stability analyses prove the stability of the material up to 180 °C and in slightly acidic to slightly alkaline solutions. The analysis of the gravimetric thermal data shows that the thermal treatment is a feasible end of life management route for this material. The values of percentage uptake and bed capacity indicate the feasibility of the use of this material in the simultaneous removal of lead, caesium and cobalt. The breakthrough curves analyses provide insights into the breakthrough characteristics and underlying removal mechanisms. It was found that the removal reaction follows Langmuir kinetics of adsorption–desorption and that the rate driving forces follow second order reversible reaction kinetics, where the sorption occur at energetically equal sites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Radioactive wastes are generated with varying compositions from a variety of activities that associate the application of nuclear sciences and technology in many fields. Of these wastes, radioactive effluents are generated during the operation of nuclear power plants, research reactors, isotope production laboratories, research centres, etc. Moreover, they are generated during the decontamination and decommissioning activities of these facilities (IAEA 2022). The characteristics of these effluents are very much dependent on the generating process, where their radiological and chemical characteristics are varied considerably (IAEA 2016). In many cases, these effluents, i.e. uranium mine wastes, decontamination wastes, decommissioning wastes, are characterized by their alkalinity or acidity that can affect the chemical stability of the used materials in their treatment (Gasser et al 2022; Abdel Rahman et al 2019).

Using multi-contaminants in environmental studies or experiments instead of a single contaminant can be beneficial for several reasons, where it provides realistic representation of environmental conditions as in the natural environment, the contaminants rarely exist in isolation. Water, air, and soil are often exposed to multiple contaminants simultaneously. Additionally, studying a single contaminant may not capture the complex interactions and synergistic effects that can occur in the presence of multiple pollutants. These combined effects of multiple contaminants can sometimes be greater or lesser than the sum of their individual effects. In this respect, studying only one contaminant may not reveal these interactive effects, which are crucial for understanding the overall environmental impact. Exposure to one contaminant may alter the fate, transport, and toxicity of other contaminants. These interactions can be unpredictable and may only become apparent when studying the combined effects of multiple pollutants. Multi-contaminant studies contribute to a more holistic assessment of environmental risk. This approach considers not only the immediate effects of individual pollutants but also their combined impact, leading to a more comprehensive understanding of potential risks to ecosystems and human health (Backhaus and Faust 2012; Song et al. 2023).

Several contaminants co-exist in these effluents that include both the radioactive contaminants and heavy metals. Subsequently during the design for the treatment practice for these wastes, there is a need to address not only the radiological hazards but also the chemical hazards. In particular, the planned treatment process should be tested to investigate its efficiency in removing different types of radiological and chemical contaminants under varying operating conditions to enable the designer to attain a safe cost effective removal process. One of the conventional treatment methods, which has been widely applied in wastewater and radioactive effluent treatment is the ion exchange/sorption process (IAEA, 1967). This wide scale application is supported by the ease of the operation, and high efficiency of the process.

Nanocomposites are formed of two or more materials, this class of materials received considerable attention in wastewater treatment research within the last decade (Abdel Rahman et al. 2021, 2022; Son et al. 2021). This is attributed to their unique characteristics that stem from the integration of the characteristics of their forming materials (Pacheco and Buzea 2021). In hazardous effluent treatment, nanocomposites were widely investigated to address some technical and safety concerns of nanomaterials applications, which include the reduced efficiency as a result of particles agglomeration, difficulty of the solid/liquid phase separation, lack of compatibility assessments with subsequent hazardous wastes immobilization and disposal activities, potential health risks due to nano-toxicity that associate the handling of these materials throughout their life cycles, increased health risks during the management of exhausted nano materials, and lack of adequate discharge legislations (Abdel Rahman et al 2021). In particular, polymer nanocomposites (PNC) can provide an additional environmental benefit over non-polymer nanocomposites in hazardous waste management, where the use of non-toxic polymer can greatly reduce the footprint of the treatment process by eliminating the generation of hazardous chemical during the synthesize process and during its end of life cycle management.

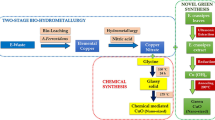

Poly(vinyl alcohol) (PVA) is characterized by its non-toxicity, excellent chemical resistance, and physical properties, biodegradation, good mechanical strength and water absorption characteristics (Chang et al 2022; Cao et al 2022; Kumar et al 2022; Sun et al 2020). These favourable chemical and physical characteristics boosted the research to investigate its use in preparing different PNCs for their potential applications in hazardous wastewater treatment. Recent applications for PVA in the preparation of PNC include; assessment for PVA-TiO2 in photocatalytic degradation (Yeo et al 2020), PVA-Ag as nanofiltration membrane (zhang et al 2016), PVA-Alg-zeolite and PVA-zeolite in sorption of heavy metals (Isawi 2020; Rad et al 2014). In particular several researchers investigated PNCs with PVA polymeric matrix- materials for the removal of radio-contaminants of concern from aqueous solutions, where PVA-carbon nano tube was tested for its application in uranium sorption and PVA-CeO for rare earth recovery (Comandella et al 2021), and PVA-potassium copper hexacyanoferrate was tested for its Cs removal form aqueous solutions (Kim et al 2017). Moreover, PVA was employed with other polymers for the encapsulation of the nanomaterials, where PVA-alginate, PVA-alginate-poly-ethyleneoxide—were tested from the removal of several metals including actinides (Tabatabaeefar et al. 2020; Talebi et al. (2017); Zahakifar et al. 2021; Majidnia and Idris 2015; Jang and Lee 2016). Of these researches limited work was devoted to address the continuous removal of the contaminant using fixed bed column (Jang and Lee 2016). In this work, the performance of PNC with PVA polymeric matrix in removing multi-contaminants simultaneously from aqueous solution in continuous operation mode will be investigated to acquire insights into the potential application of this material in radioactive effluent treatment. In this respect, mixed valent tunnel structured manganese oxide nano-material was selected for this application. This selection is supported by the ability of manganese oxides to remove different contaminants from their solutions (Della Puppa, et al 2013; Ghaly et al 2016, 2018; 2022; Metwally et al 2017; Mahmoud et al 2021; Qu et al 2022; Zhang et al 2023). A simple and environmental friendly method was adopted to rapidly fabricate PVA gel beads with homogeneous structure. The prepared PNC was characterized to evaluate the nature of nanoparticle inclusion into the PVA matrix, and its chemical and thermal stability. The simultaneous removal of Cs, Co, and Pb were considered to cover different types of contaminants in radioactive waste effluents. The effect of the variation of the continuous operational mode parameters, i.e. bed depth and flow rate, and solution characteristics, i.e. initial contamination of the aqueous solution on the simultaneous removal performance of this material was assessed in terms of the contaminant percentage uptake and the bed capacity for all the studied contaminants. Finally, the breakthrough curves of the contaminant removal were mathematically analysed to provide insights into the breakthrough characteristics and underlying removal mechanisms.

Experimental

Materials

Mixed-valent manganese oxide with tunnel structure was prepared following an oxidation procedure under acidic conditions (Chenney et al. 2006; Ghaly et al 2018; 2022). Analar purity grade PVA ([CH2CH(OH)]n,; Merck), Boric acid (H3BO3; El-Gomhouria), and calcium chloride (CaCl2; Fluka) were used for the preparation of the polymeric matrix without further purification. Caesium chloride (CsCl; Fluka), cobalt chloride hexahydrate (Co(Cl)2.6H2O; Merck), and lead chloride hexahydrate (Pb(Cl)2.6H2O; Merck) were used to prepare stimulant for contaminated effluent, where stock solution was prepared by dissolving the appropriate amount of analytical grade salts in double-distilled water.

Polymer nanocomposite synthesis

PNC beads were synthesized by a facile environmental friendly chemical cross-linking of the PVA using boric acid (Sun et al 2020). In this respect, 2 g of mixed-valent manganese oxide was mixed with 10% (w/w) aqueous PVA solution. The formed mixture was dropped into an aqueous solution comprises of saturated H3BO3 and CaCl2, and kept for 2.0 h to allow the cross-linking of the beads. The beads were washed several times with distilled water, and stored for further use. The nanocomposites were formed by the interaction between MnO2 nanoparticles and hydroxyl groups (–O–H) within the PVA matrix as shown in Scheme 1.

Polymer nanocomposite characterization

Characterization of the prepared PNC was carried out using field emission scanning electron microscope (FE-SEM) attached with energy dispersive X-ray analysis (EDX; Philips XL 30, USA) unit to investigate the morphology of the material, the dispersion of the nanoparticles, and determine its chemical composition. The chemical stability (S, %) of the PNC was tested by measuring the gravimetric differences of the material before (m1, mg) and after (m2, mg) contacting different acidic and alkaline solutions (pH = 2–10), where the stability is calculated as follows (Gasser et al 2016):

Thermal stability of the material and its potential end of life management were studied by analysing the results of the differential thermal analysis (DTA) and thermal gravimetric data (TGA; Shimadzu DTA–TGA system of type DTA-TGA-60 H, Japan). In this respect, TGA data were analysed using the combination of integrated Clausius − Clapeyron and Langmuir equations, Eq. (2) (Flores et al. 2018; Barron, 2010).

In this method, the measured rate of mass loss (dm/dt; kg/s) and temperature (T; K) are used to obtain the change in enthalpy during the reaction (ΔH; kJ/mol), where R is the gas constant (8.34 J/mol), D is diffusion coefficient (m2/s), S characteristic factor, M molar mass of resin (M).

PNC performance in continuous operational mode

The performance of the PNC was tested in vertical down flow fixed bed column as shown in Fig. 1. The material was packed in the column after placing a thin layer of glass wool at the bottom. The column was plugged by placing a small glass wool plug on the top of the bed and the packing density was calculated. Column preconditioning was achieved using HNO3 at a suitable flow rate to removes all air pockets from the bed. The performance was tested under varying flow rates (1–3 ml/min), bed depths (2–4 cm) and metal ion concentrations (5 × 10–3–5 × 10−4 mol/l). The percentage removal (P, %) and total sorbed ion (qt, mg/g) were used as performance measures to investigate the effect of the operating conditions variation on the removal process. The percentage removal (Eq. 3) and the total sorbed ions (Eq. 4) were calculated as follows(Mitra & Kumar 2019):

, where Cx is the initial contaminant concentration (mg/l) in the solution at initial (x = o) and final (x = t) time, Veff is the effluent volume (ml) and Q is the flow rate (ml/min). Mathematical analyses of the continuous removal performance were conducted using three models to have insights into the dynamic performance, potential mechanism and determine the reaction parameters. In this context, the nonlinear forms of Adams Boahrt (Eq. 5), Thomas (Eq. 6),and Clark (Eq. 7) models were used to analyse the experimental data((Ebrahimi-Gatkash et al. 2017; Tagbo et al. 2022; Omitola et al. 2022; Bharathi et al. 2013).

, where xx is the rate coefficient (ml min−1 mmol−1) for Adam Boahrt model (x = AB), Thomas (x = T), and Clark (x = f), respectively. No is the adsorption capacity of the adsorbent per unit volume of the bed (l−1 mmol), z is the bed depth (cm), Uo is the linear flow rate (cm min−1), qo is the sorption capacity (mmol g−1), M the bed mass (g), Q flow rate (ml min−1), and n is the Freundlich constant.

Results and discussion

Material characterizations

The morphological analysis of the prepared PNC indicated that the prepared material is spherical micro beads that has a radius equals 1.447 ± 0.008 mm (Fig. 2a). The beads have lamellar morphology (Fig. 2a) where inclusions of agglomerated metallic nanoparticles appear in the material (Fig. 2b). The analysis of the agglomerated nanoparticle size and shape within the beads was conducted using ImageJ, and the major and minor diameters of these inclusions and their circularity were statistically analysed (Fig. 2c, d). This analysis revealed that the agglomerated particles (> 600 nm) have elliptic shapes, where their circularity (Cir) follow normal distribution (Cir = 0.6 ± 0.19; Fig. 2c). The major and minor axes of the agglomerated particles follow lognormal distribution and their means are 3.6 and 2.23 μm, respectively (Fig. 2d; Table 1). The elemental mapping of manganese within the beads reflects that in addition to the agglomerated nanoparticles, there is a fairly homogenous inclusion of these particles in PVA matrix (Fig. 2e). The EDS results indicated that the weight of the carbon is more than double the manganese and potassium (Table 2).

The specific surface area (SSA) of the mixed manganese oxide was previously calculated and found to be 299.03 m2/g (Ghaly et al. 2022), we recommend consideration of pore size distribution in the future work.

A speciation study was conducted using visual Minteq to optimize the initial concentration of the contaminants in the solution to prevent precipitation or co-precipitation of the contaminants during the course of the work. In this respect, the effects of the variation in the pH of the solution in the range 2–10 and the initial concentration of the contaminants in the solution on the speciation of the studied contaminants at room temperature were evaluated. Figure 3a and b) displays the calculated saturation indices for the studied contaminants species and the percentage distribution of these species; it is obvious that the acidic solutions with pH in the range (2–5) contains only monovalent caesium ions (Cs+) and divalent cobalt (Co+2) and lead ions (Pb+2). The reduction in the solution acidity is associated with respectively, rapid increase in the formation of Pb(OH) to reach a maximum at pH 8 and slower build-up of Co(OH). For the studied solutions, Pb(OH)2 is having a potential to precipitate at pH ≥ 8 and this trend increase with increasing the contaminant concentration in the range (1 × 10–4–1 × 10–2 mol/l) (Fig. 3a). As the initial concentration increase the possibility of the precipitation of crystalline and amorphous Co(OH) increases at pH ≥ nine depending on the initial concentration. At the highest studied concentration, the trace species tend to precipitate, i.e. Pb2(OH)3Cl and CoO. The investigation of the plot of the percentage distribution of the species for solution containing equi-molar concentration of the studied contaminant equals 10–3 mol/l (Fig. 3b) indicates that the solution has pH = 6.7. At this pH, the solution contains only monovalent Cs and divalent cobalt, where lead is found as a mixture of the divalent species Pb+2 (87.72%) and monovalent species Pb(OH)+ (12.24%) with the presence of other trace species. These results revealed the possibility of using the initial concentration in the range (1 × 10–4–1 × 10−2mol/l) without potential precipitation of the major species in the solution in the pH range 5–8. The stability of the PNC beads is dependent on the pH of the solution (Fig. 3c), with minimum stability in highly acidic solutions. The stability of the beads is maximum at pH 5 (94.43%) and it reduces gradually in neutral and alkali solutions. In the range pH 5–8 the material has the highest stability range > 76%, which proposes that the material can be used in slightly acidic to slightly alkali media without considerable losses in its chemical stability. The speciation and the chemical stability results show that the material application in the removal of these contaminants is not limited by its chemical stability. Comparing the stability of the prepared PNC beads with those of Alginate-cyanex 301 beads, it is clear that the stability of the first is very much comparable in this pH range to that of medium and high alginate concentrations (Gasser et al 2020).

TGA results show progressive gravimetric losses with increasing the temperature in the range 30–600 °C (Fig. 4a). These losses represent nearly 81% of the initial mass of the PNC beads. A previous study recorded that 62–87% overall mass losses could be achieved for different commercial cationic and anionic resins at 600 °C during their end of life management (Dubois et al., 1995). These results reflect that the thermal treatment can be considered as a feasible technical option to reduce the volume of the exhausted resins at the end of their life cycle. The relatively low temperature of the thermal degradation process allows the proposal of using conventional incinerator or pyrolysis reactor to incinerate the exhausted resins followed by ash immobilization in a suitable waste matrix (Abdel Rahman and Zaki 2009). The overall mass loss proceeds on four stages;.the first occurs at temperature less than 180 °C and represents about 4.2% of the total weight of the sample which results from the loss of the uncoordinated interlayer water (Peng et al. 2013). This is an indication of the thermal stability of the material in this temperature range. The second stage is divided into two steps with weight loss of about 35.25%; on one hand the first step is visible in the temperature range 180–320 °C ascribes to the decomposition of PVA with weight loss about 20.47%, which is attributed to the de-hydrochlorination of the PVA and is associated with the release of HCl and C6H6 gases and the formation of conjugated double bonds (Mallakpou et al., 2014; Zhou et al. 2015). On the other hand, the second step occurs at temperature between 320 and 380 °C, and is attributed to the loss of oxygen content due to internal changes in mixed valent manganese oxide (Ghaly et al 2018). The third stage occurs with about 39.23% weight loss in the range of 380–520 °C, due to the decomposition of the remaining PVA and its further degradation into carbon char, (Yang et al. 2012). This stage represents the well- known second pyrolysis stage for PVA, where the products of the dehydrochlorination continue with cracking to low hydrocarbons of linear or cyclic structure (Zhu et al 2008; Zhou et al. 2015).The fourth stage accompanied by a weight loss of 2.63% occurs between 520 and 600 °C arises from the phase change in the mixed valent manganese oxide structure (Ghaly et al 2018). DTA curve of nanocomposite beads shows three endothermic peaks, one located at 253, 360, and 547 °C which corresponding to decomposition of PVA and the phase transformation of the mixed valent oxide (Fig. 4b).The presence of two reactions for the decholrination of the material at about 253 and 360 was explained by the occurrence of two parallel reactions, in the first PVC is decomposed into intermediate species and HCL then these intermediates are decomposed into polyene and some volatiles (Castro et al. 2012; Zhou et al. 2015, 2019),

Additionally, two exothermic peaks are noted in the DTA pattern at 56 and 470 °C that correspond to the release of bounded water and decomposing of the remaining PVA, respectively. Figure 4c reveals the occurrence of multiple reactions during the thermal degradation of the prepared PNC. The changes in enthalpy due to these reactions were determined according to Eq. (2), the enthalpy change due to the exothermic reaction of water evaporation in the range 30–180 °C is achieved via two subsequent reactions of enthalpy change equals − 42.38 and − 37.75 kJ/mol. Three endothermic and exothermic reactions occur in the range 180–320 °C. The endothermic reactions (ΔH = 20.72 and 40.72 kJ/mol) and the exothermic reactions (ΔH = − 65.39 kJ/mol) associate the PVA first decomposition. The oxygen release from the nanoparticle and the complete decomposition of PVA is associated with two exothermic (ΔH = − 62.44, − 94.09 kJ/mol) and an endothermic (ΔH = 134.26 kJ/mol) reactions. It should be noted that the activation energy for the reaction that occurred in the last decomposition stage was reported to equal 191 kJ/mol in the temperature range (392–522) (Wang et al 2019).

PNC performance under continuous operation

The studied PNC is having the largest affinity to remove lead from the solution, followed by caesium then cobalt. This affinity is not affected by the column bed depth, solution flow rate and initial concentration of the contaminants (Fig. 5a, b). Both the bed capacity, i.e. total sorbed contaminant amount, and the percentage removal of all the contaminants increase with increasing bed depth as shown in Fig. 5a, b, as more binding sites are available for the sorption of contaminants (El-Kamash 2008). Both performance measures are affected negatively by increasing the flow rate and the initial contaminants concentration, as a result of the reduced contact time between the sorbent and the contaminant causing weaker distribution of the liquid inside the bed, which leads to a lower diffusivity of the contaminant among the PNC beads and increased filling of available active sites at higher concentration, respectively (Petrova et al. 2016). The material has larger affinity toward Pb compared to Cs and Co. Its maximum capacity for Pb, Cs, and Co are 0.326, 0.261, 0.152 mmol/g, respectively. The corresponding conditions for these capacities are initial contaminant concentration 5 mmol/l, bed depth 3 cm, and flow rate 1 ml/l. Figure 6 illustrates the elemental distribution of the contaminants onto the prepared PNC bead. It is clear that the contaminants are not only sorbed onto the Manganese structure but also sorbed onto the PVA structure, where the area (I) shows very limited distribution for the manganese element and intense distribution Pb, Cs, and Co elements.

Effect of bed depth

The breakthrough curves for the simultaneous removal of the studied contaminants at different bed depth 2–4 cm are shown in Fig. 7a–i, Pb breakthrough curves have longest lag phase, the steepest logarithmic phase and shortest saturation phase, which is translated to the largest treated effluent volume. The analysis of the breakthrough curve using the nonlinear form of AB (Eq. 5), Thomas (Eq. 6), and Clark (Eq. 7) model equations revealed that Clark model is the best describing model equation to represent the system independently on the bed depth or the contaminant (Table 3 and Fig. 7a–i). The fittings of the experimental data to AB model have correlation coefficients (R2) in the range 0.751–0.939. Despite the high values of R2, changes are noted in the values of the adsorption capacity of the adsorbent per unit volume (No) without noted trend. The tabulated values of the correlation coefficients for Thomas and Clark nonlinear fitting analysis are very close and higher than those obtained for AB model. This entails that the removal reaction follows Langmuir kinetics of adsorption–desorption and that the rate driving forces follow second order reversible reaction kinetics (Xu et al 2013; Wang et al 2015). The Freundlich constant (n) in Clark model is nearly equal unity which indicate that the Freundlich isotherm is reduced to Langmuir isotherm that employed that the removal occur at fairly energetically equal sites (Table 4). Similar finding of the reduction of Freundlich isotherm to Langmuir isotherm was reported for the sorption of Cr(VI) onto grafting copolymerization of styrene and divinylbenzene onto polypropylene fibre (Wang et al. 2015).

The analysis of the residual errors of the studied models indicates that during the lag phase, all the models are fairly representing the data well (Fig. 7). Prior to the breakthrough point, AB model starts to overestimate the breakthrough data largely compared to the other two models. During the logarithmic phase, the application of AB models leads to large underestimations in the values of the fractions of removed contaminant concentrations. Finally during the stationary phase, the AB model overestimated the data. These wide dispersions of the residual errors have led to the low correlation coefficients for that model especially for Cs and Co removal data (Fig. 7). The values of the residual errors from Thomas and Clark models fittings have minimum values within the lag and the stationary values that approaches zero. During the logarithmic phase, the residual errors from these models are having oscillating behaviour around zero. From Fig. 7a–i it could be concluded that all the breakthrough data follow Clark model.

Effect of flow rate

The breakthrough curves for the simultaneous removal of the studied contaminants at different flow rates 1–3 ml/min are shown in Fig. 8a–i, increasing the flow rate of the solution will reduce significantly the lag time and increase the logarithmic phase time for all the studied contaminants. The analysis of the breakthrough curve using AB, Thomas, and Clark model equations revealed that both Thomas and Clark models are best describing the experimental data independently on the flowrate value or the contaminant type (Table 4). The tabulated values of the correlation coefficients for Thomas and Clark nonlinear fitting analysis are very close and higher than those obtained for AB model. The dispersions of the residual errors are the highest for the AB model, where the application of this model can lead to considerable.

Underestimation and overestimation of the concentration in the lag and the logarithmic phase, similar to the results obtained from studying the effect of bed depth. Thomas and Clark models are having smaller residual errors that slightly increase by in the beginning of the logarithmic phase by increasing the flow rate for all the contaminants. This entails the same conclusion obtained from the study of the effect of bed depth on the removal process. Similar to the findings from the bed depth study, Freundlich constant (n) in Clark model is nearly equal unity which indicates that the Freundlich isotherm is reduced to Langmuir isotherm that employed that the removal occur at fairly energetically equal sites (Table 4).

Effect of initial contaminant concentration

Increasing the initial contaminants concentration in the solution reduces the lag phase in the breakthrough curves as a result of the rapid filling of the active sites (Fig. 9a–i). The analysis of the breakthrough curve using AB, Thomas, and Clark model equations revealed that Clark model is the best describing model equation to represent the system independently on the initial concentration value or the contaminant type (Table 5 and Fig. 9a–i). The distributions of the residual errors from fitting the experimental data to AB model showed similar behaviour to that resulted from fitting the experimental data of the effect of bed depth and effect of flow rate. The tabulated values of the correlation coefficients for Thomas and Clark nonlinear fitting analysis are also very close and higher than those obtained for AB model. This entails the same conclusion obtained from the study of the effect of bed depth and the effect of flow rate on the removal process. Similar to the results of the effect of bed depth and effect of flow rate investigations, Freundlich constant (n) in Clark model is nearly equal unity which indicate that the Freundlich isotherm is reduced to Langmuir isotherm that employed that the removal occur at fairly energetically equal sites (Table 5).

Analysis of the breakthrough curve characteristics

To have insights into the breakthrough curve characteristics, the lag times (λ, min), the maximum specific breakthrough rates (μmax, min−1), and half the operating times (t0.5, min) were determined from the fitting data of Clark models as follows (Hu et al 2020):

The μmax represents the slope of the tangent line at the inflection point in the breakthrough curve, whereas λ and t0.5 are the times required before the breakthrough point and half the operating time of the column. Figure 10 a–illustrates the variation of the breakthrough characteristics for the column parameters and initial concentration of the contaminants. It is clear that the times required for the breakthrough and half the operating times are having fairly similar trends, where the trend changes with the variation of the bed depth, flow rate and initial concentration values. The minimum operational time is obtained for highest initial concentration, i.e. 38 min, will yield in highest apparent capacity and removal percentages of 84.31, 81.92, and 72.34% for Pb, Cs, and Co, respectively.

The longest operational time is about 140 min for a bed depth equals 4 cm will yield in the highest uptake of 92.33, 86.11, and 69.07% for Pb, Cs, and Co, respectively which are higher than that reported by (Dutta et al. 2022) 72% and 60% for Cd and Co, respectively at threshold concentrations. The behaviours of the maximum specific breakthrough rates are not only dependent on the column parameters and the initial concentration but also dependent on the studied contaminant. As this parameter is an indication on how fast is the logarithmic phase can proceed, the mass transfer zones for both Cs and Pb are characterized with fairly straight and steep slope.

Conclusion

In this work the feasibility of using the PNC in simultaneous continuous removal of multi-contaminants from their solution were investigated. The following remarks can be drawn:

-

1.

The morphological analysis revealed fairly homogenous distribution of the nano-materials in the PVA matrix with some inclusion of agglomerated nanoparticles,

-

2.

The material is thermally stable without any structural losses up to 180 °C, and chemically stable in pH5-8,

-

3.

The speciation results and the chemical stability results reveal that the material application in the removal of these contaminants is not limited by its chemical stability,

-

4.

The analysis of the gravimetric thermal data of the PNC indicate that the thermal degradation treatment is a feasible technical option to reduce the volume of the exhausted beads at the end of their life cycle,

-

5.

The values of the percentage uptake and bed capacity indicate that the material favour the simultaneous removal of lead, caesium, and cobalt, and has higher tendency for lead followed by caesium then cobalt,

-

6.

The analysis of the breakthrough curves indicate that Pb removal is characterized with longest lag phase, the steepest logarithmic phase and shortest saturation phase, which is translated to the largest treated effluent volume under all the studied conditions,

-

7.

The application of the AB model to fit the breakthrough experimental data will lead to considerable underestimation and overestimation of the concentration in the lag and logarithmic phases, respectively and independently on the studied conditions,

-

8.

The removal reaction follows Langmuir kinetics of adsorption–desorption and the rate driving forces follow second order reversible reaction kinetics, where the removal occurs at fairly energetically equal sites.

-

9.

Despite having previously determined and reported the specific surface area (SSA) of the mixed manganese oxide, we advise incorporating an analysis of the pore size distribution of PVC in future research.

References

Abdel Rahman RO, Zaki AA (2009) Assessment of the leaching characteristics of incineration ashes in cement matrix. Chem Eng J 155:698–708. https://doi.org/10.1016/j.cej.2009.09.002

Abdel Rahman RO, Abdel Moamen OA, Abdelmonem N, Ismail IM (2019) Optimizing the removal of strontium and cesium ions from binary solutions on magnetic nano-zeolite using response surface methodology (RSM) and artificial neural network (ANN). Environ Res 173:397–410. https://doi.org/10.1016/j.envres.2019.03.055

Abdel Rahman RO, AbdelMoamen OA, El-Masry EH (2021) Life cycle of polymer nanocomposites matrices in hazardous waste management. In: Hussain CM, Thomas S (eds) Handbook of polymer and ceramic nanotechnology, vol 17. Springer, Switzerland AG, pp 1603–1625

Abdel Rahman RO, El-Kamash AM, Hung Y-T (2022) Applications of nano-zeolite in wastewater treatment: an overview. Water 14:137. https://doi.org/10.3390/w14020137

Backhaus T, Faust M (2012) Predictive environmental risk assessment of chemical mixtures: a conceptual framework. Environ Sci Technol 46(5):2564–2573

Barron, A.R. (2010) Determination of sublimation enthalpy and vapor pressure for inorganic and metal-organic compounds by thermogravimetric analysis, connexions module:M33649, ttp://cnx.org/content/m33649/1.2/

Bharathi KS, Biosorption K, Crystal Á, Bdst Á, Thomas Á, Nelson ÁY (2013) Fixed-bed column studies on biosorption of crystal violet from aqueous solution by Citrullus lanatus rind and Cyperus rotundus. Appl Water Sci 3:673–687. https://doi.org/10.1007/s13201-013-0103-4

Cao J, Zhao X, Ye L (2022) Super-strong and anti-tearing poly (vinyl alcohol)/graphene oxide nano-composite hydrogels fabricated by formation of multiple crosslinking bondingnetwork structure. J Ind Eng Chem 112:366–378

Castro A, Soares D, Vilarinho C, Castro F (2012) Kinetics of thermal de-chlorination of PVC under pyrolytic conditions. Waste Manage 32(5):847–851

Chang S, Fu H, Wu X, Liu C, Li Z, Dai Y, Zhang H (2018) Batch and fixed-bed column studies for selective removal of cesium ions by compressible Prussian blue/polyurethane sponge. RSC Adv 8(64):36459–36467

Chang YR, Lee YJ, Lee DJ (2022) Synthesis of pH, thermally, and shape stable poly (vinyl alcohol) and alginate cross-linked hydrogels for cesium adsorption from water. Environ Technol Innov 27:102431

Cheney MA, Birkner NR, Ma L et al (2006) Synthesis and characterization of inorganic double helices of cryptomelane nanomaterials. Colloids Surf A 289:185–192

Citations should appear here in the format A. Name, B. Name and C. Name, Journal Title, 2000, 35, 3523; A. Name, B. Name and C. Name, Journal Title, 2000, 35, 3523.

Comandella D, Bonani W, Ciscar JB, Ponti J, Cologna M, Popa K, Gilliland D (2021) Recovery of rare earth elements by nanometric CeO2 embedded into electrospun PVA nanofibres. RSC Adv 11(32):19351–19362

Della Puppa L, Komárek M, Bordas F, Bollinger JC, Joussein E (2013) Adsorption of copper, cadmium, lead and zinc onto a synthetic manganese oxide. J Colloid Interface Sci 399:99–106

Dubois MA, Dozol JF, Nicotra C, Serose J, Massiani C (1995) Pyrolysis and incineration of cationic and anionic ion-exchange resins - Identification of volatile degradation compounds. J Anal Appl Pyrolysis 31:129–140. https://doi.org/10.1016/0165-2370(94)00817-K

Dutta A, Mandal A, Chanda P, Misra S, Mukherjee J, Das R (2022) Biosorption of cadmium and cobalt by intertidal multicomponent biofilms. Mar Pollut Bull 185(PA):114318

Ebrahimi-Gatkash M, Younesi H, Shahbazi A, Heidari A (2017) Amino-functionalized mesoporous MCM-41 silica as an efficient adsorbent for water treatment: batch and fixed-bed column adsorption of the nitrate anion. Appl Water Sci 7(4):1887–1901. https://doi.org/10.1007/s13201-015-0364-1

El-Kamash AM (2008) Evaluation of zeolite A for the sorptive removal of Cs+ and Sr2+ ions from aqueous solutions using batch and fixed bed column operations. J Hazard Mater 151(2–3):432–45. https://doi.org/10.1016/j.jhazmat.2007.06.009

Flores H, Ramos F, Camarillo EA, Santiago O, Perdomo G, Notario R, Cabrera S (2018) Isothermal thermogravimetric study for determining sublimation enthalpies of some hydroxyflavones. J Chem Eng Data 63(6):1925–1936

Gasser MS, Mekhamer HS, Rahman RA (2016) Optimization of the utilization of Mg/Fe hydrotalcite like compounds in the removal of Sr(II) from aqueous solution. J Environ Chem Eng 4(4):4619–4630

Gasser MS, El Sherif E, Mekhamer HS, Rahman RA (2020) Assessment of Cyanex 301 impregnated resin for itspotential use to remove cobalt from aqueous solutions. Environ Res 185:109402

Gasser MS, Kadry HF, Helal AS, Abdel Rahman RO (2022) Optimization and modeling of uranium recovery from acidic aqueous solutions using liquid membrane with Lix-622 as Phenolic-oxime carrier. Chem Eng Res Des 180:25–37. https://doi.org/10.1016/j.cherd.2022.02.002

Ghaly M, El-Dars FMSE, Hegazy MM, Abdel Rahman RO (2016) Evaluation of synthetic Birnessite utilization as a sorbent for cobalt and strontium removal from aqueous solution. Chem Eng J 284:1373–1385

Ghaly M, El-Sherief EA, Metwally SS, Saad EA (2018) Utilization of nano-cryptomelane for the removal of cobalt, cesium and lead ions from multicomponent system: kinetic and equilibrium studies. J Hazard Mater 352:1–16

Ghaly M, Metwally SS, El-Sherief EA, Saad EA, Abdel Rahman RO (2022) Utilization of synthetic nano-cryptomelane for enhanced scavenging of cesium and cobalt ions from single and binary solutions. J Radioanal Nucl Chem 331(4):1821–1838

Hu Q, Xie Y, Zhang Z (2020) Modification of breakthrough models in a continuous-flow fixed-bed column: mathematical characteristics of breakthrough curves and rate profiles. Sep Purif Technol 238:116399

IAEA (1967) Operation and control of ion-exchange processes for treatment of radioactive wastes, TRS.78. International Atomic Energy Agency, Vienna

IAEA (2016) Predisposal management of radioactive waste from nuclear power plants and research reactors, Sepcific Safety Guide, No. SSG-40. International Aotmic Energy Agency, Vienna

IAEA (2022) Status and trends in spent fuel and radioactive waste management, nuclear energy series, NW-T-1.14. International Atomic Energy Agency, Vienna

Isawi H (2020) Using zeolite/polyvinyl alcohol/sodium alginate nanocomposite beads for removal of some heavy metals from wastewater. Arab J Chem 13:5691–5716

Jang J, Lee DS (2016) Enhanced adsorption of cesium on PVA-alginate encapsulated Prussian blue-graphene oxide hydrogel beads in a fixed-bed column system. Biores Technol 218:294–300

Kim YK, Kim Y, Kim S, Harbottle D, Lee JW (2017) Solvent-assisted synthesis of potassium copper hexacyanoferrate embedded 3D-interconnected porous hydrogel for highly selective and rapid cesium ion removal. J EnvironChem Eng 5:975–986

Kumar A, Sood A, Han SS (2022) Poly (vinyl alcohol)-alginate as potential matrix for various applications: a focused review. Carbohyd Polym 277:118881

Mahmoud ME, Ibrahim GA, Abdelwahab MS (2021) Manganese dioxide nanoparticles decorated with chitosan for effective removal of lead and lanthanum ions from water by microwave sorption technique. Mater Sci Eng B 267:115091

Majidnia Z, Idris A (2015) Evaluation of cesium removal from radioactive waste water using maghemite PVA–alginate beads. Chem Eng J 262:372–382

Mallakpour S, Dinari M (2014) Novel bionanocomposites of poly (vinyl alcohol) and modified chiral layered double hydroxides: synthesis, properties and a morphological study. Prog Org Coat 77(3):583–589

Metwally SS, Ghaly M, El-Sherief EA (2017) Physicochemical properties of synthetic nano-birnessite and its enhanced scavenging of Co2+ and Sr2+ ions from aqueous solutions. Mater Chem Phys 193:63–72

Mitra T, Kumar S (2019) Cr(VI ) removal from aqueous solution using Psidium guajava leaves as green adsorbent : column studies. Appl Water Sci 9(7):1–8. https://doi.org/10.1007/s13201-019-1029-2

Omitola OB, Abonyi MN, Akpomie KG, Dawodu FA (2022) Adams-Bohart, Yoon-Nelson, and Thomas modeling of the fix—bed continuous column adsorption of amoxicillin onto silver nanoparticle—maize leaf composite. Appl Water Sci 12(5):1–9. https://doi.org/10.1007/s13201-022-01624-4

Pacheco I, Buzea C (2021) Nanomaterials and nanocomposites: classification and toxicity. In: Kharissova OV, Torres-Martínez LM, Kharisov BI (eds) Handbook of nanomaterials and nanocomposites for energy and environmental applications. Springer, Cham. https://doi.org/10.1007/978-3-030-36268-3_1

Peng P, Yang Z, Wu M, Zhang Q, Chen G (2013) Effect of montmorillonoite modification and maleic anhydride-grafted polypropylene on the microstructure and mechanical properties of polypropylene/montmorillonoite nanocomposites. J Appl Polym Sci 130(6):3952–3960

Petrova YS, Pestov AV, Neudachina LK (2016) Removal of metal ions in fixed bed from multicomponent solutions using N-(2-sulfoethyl) chitosan-based sorbents. Sep Sci Technol 51(9):1437–1445. https://doi.org/10.1080/01496395.2016.1157085

Qu J, Che N, Niu G, Liu L, Li C, Liu Y (2022) Iron/manganese binary metal oxide-biochar nano-composites with high adsorption capacities of Cd2+: preparation andadsorption mechanisms. J Water Process Eng 51:103332

Rad LR, Momeni A, Ghazani BF, Irani M, Mahmoudi M, Noghreh B (2014) Removal of Ni2+ and Cd2+ ions from aqueous solutions using electrospun PVA/zeolite nanofibrous adsorbent. Chem Eng J 256:119–127

Son BT, Long NV, Hang NTN (2021) Fly ash-, foundry sand-, clay-, and pumice-based metal oxide nanocomposites as green photocatalysts. RSC Adv 11(49):30805–30826

Song S, Liu S, Su C, Lu Y (2023) Multimedia modeling of the fate for emerging pollutants. In: Lu Y, Wang P, Yuan J (eds) Ecological risks of emerging pollutants in urbanizing regions. Springer, Berlin, pp 97–207

Sun L, Wang J, Liang J, Li G (2020) Boric acid cross-linked 3D polyvinyl alcohol gel beads by NaOH-titration method as a suitable biomass immobilization matrix. J Polym Environ 28(2):532–541

Tabatabaeefar A, Keshtkar AR, Talebi M, Abolghasemi H (2020) Polyvinyl alcohol/alginate/zeolite nanohybrid for removal of metals. Chem Eng Technol 43:343–354

Tagbo J, Ositadinma N, Iheanacho C, Chiedozie C, Onu CE (2022) Linear and nonlinear kinetics analysis and adsorption characteristics of packed bed column for phenol removal using rice husk - activated carbon. Appl Water Sci 12(5):1–16. https://doi.org/10.1007/s13201-022-01635-1

Talebi M, Abbasizadeh S, Keshtkar AR (2017) Evaluation of single and simultaneous thorium and uranium sorption from water systems by an electrospun PVA/SA/PEO/HZSM5 nanofiber. Process Saf Environ Prot 109:340–356

Wang W, Li M, Zeng Q (2015) Adsorption of chromium(VI) by strong alkaline anion exchange fiber in a fixed-bed column: experiments and models fitting and evaluating. Sep Purif Technol 149:16–23

Wang Z, Xie T, Ning X, Liu Y, Wang J (2019) Thermal degradation kinetics study of polyvinyl chloride (PVC) sheath for new and aged cables. Waste Manage 99:146–153

Xu Z, Cai JG, Pan BC (2013) Mathematically modeling fixed-bed adsorption in aqueous systems. J Zhejiang Univ Sci A 14(3):155–176

Yang Y, Gao N, Chu W, Zhang Y, Ma Y (2012) Adsorption of perchlorate from aqueous solution by the calcination product of Mg/(Al–Fe) hydrotalcite-like compounds. J Hazard Mater 209(210):318–325

Yeo JH, Kim M, Lee H, Cho J, Park J (2020) Facile and novel eco-friendly poly (vinyl alcohol) nanofilters using the photocatalytic property of titanium dioxide. ACS Omega 5(10):5026–5033

Zahakifar F, Keshtkar AR, Talebi M (2021) Performance evaluation of sodium alginate/polyvinyl alcohol/ polyethylene oxide/ZSM5 zeolite hybrid adsorbent for ion uptake from aqueous solutions: a case study of thorium (IV). J Radioanal Nucl Chem 327:65–72

Zhang Y, Wan Y, Shi Y et al (2016) Facile modification of thin-film composite nanofiltration membrane with silver nanoparticles for anti-biofouling. J Polym Res 23:105–114. https://doi.org/10.1007/s10965-016-0992-7

Zhang C, Wu M, Wu K, Li H, Zhang G (2023) Efficient removal of antimonate and antimonite by a novel lanthanum-manganese binary oxide: performance and mechanism. J Hazard Mater 442:130132

Zhou H, Long Y, Meng A, Li Q, Zhang Y (2015) Interactions of three municipal solid waste components during co-pyrolysis. J Anal Appl Pyrol 111:265–271

Zhou R, Huang B, Ding Y, Li W, Mu J (2019) Thermal decomposition mechanism and kinetics study of plastic waste chlorinated polyvinyl chloride. Polymers 11(12):2080

Zhu HM, Jiang XG, Yan JH, Chi Y, Cen KF (2008) TG-FTIR analysis of PVC thermal degradation and HCl removal. J Anal Appl Pyrol 82(1):1–9

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

There are no conflicts to declare.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ghaly, M., Abdel Rahman, R.O. Theoretical investigations of the potential application of PVA-mixed-valent tunnel structured manganese oxide nano-composite in continuous simultaneous removal of multi-contaminants from aqueous waste stream. Appl Water Sci 14, 155 (2024). https://doi.org/10.1007/s13201-024-02158-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-024-02158-7