Abstract

Environmental contamination by heavy metals has continued to be a source of serious concerns to researchers because of its far-reaching implications on the earth as we know it. This is because environmental pollution occasioned by heavy metals (HMs) which are non-biodegradable pose direct or indirect negative effects on environmental health, including that of plants, animals, and humans owing to their increased bioaccumulation in environmental matrices. Wastewater from industries producing chemicals is disposed of directly without proper treatment into the environment. However, HMs enter the food chains and food webs via the air, water, and soil, thereby inducing several diseases and disorders in both humans and animals. The features of rice husk (RH) as novel adsorbent are because it is chemically stable as well as being insoluble in water in addition to its large surface area relative to other agricultural waste products. There is an increasingly high awareness of the roles played by RH in environmental uses or applications for the sequestration of environmentally harmful chemical substances This review summarizes some recent developments in the use of RH and its derivatives as an environmentally friendly adsorbent that is highly suitable for the removal of heavy metal.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

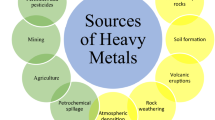

Heavy metal contamination simply means the anthropogenic introduction, direct or indirectly of toxic HMs in any environmental medium in such an elevated concentration beyond natural background level in the environment and living organisms. Environmental contamination by toxic elements is a global problem because of its persistence nature (Okoro et al. 2012; Okoro et al. 2018; Basheeru et al. 2021). Studies have shown that these released toxic elements from industrial and agricultural wastes could undergo several physiochemical processes in the environment, especially in lagoon system which can lead to different organic and in organic speciation in marine environment (Okoro et al. 2014; Okoro et al. 2017; Basheeru et al. 2020). The target organ toxicity of heavy metals in human beings is provided in Fig. 1. Studies have documented that air, water, and soil are the natural sinks for HMs but soil serves as the most important geochemical sink of HM pollution (Infotox 2000) (Fig. 2). Be that as it may, as of late the general environmental contamination in both developed and developing nations moves toward becoming serious.

In Europe, Toth et al. (2016) reported that an estimated 6.24% of total agricultural lands are contaminated and need remediation actions while Panagos et al. (2013) put heavy metals and mineral oil as the main contaminant of soil with 60% quota. In sub-Saharan Africa, UNEP (2011) estimated heavy metals concentrations in water, soil, and air in ten communities of Ogoniland of Nigeria was almost 1000 times greater than the allowable threshold levels. Heavy metal (HM) contamination was not previously given significant consideration but in recent times, it has become serious issues of concern worldwide due to their increased use and processing in various. It is based on the global threat of a rapid increase in environmental contamination by HMs that more consideration is put on the remediation of HMs in environmental media such as soil and water. Adsorption method as a remedial technique for HM contamination in soil and aqueous media has been proposed because nearly all HM ions can be remedied and adsorbed via adsorbents (Wang and Zhou 2004). There are several adsorbents used to immobilize and remove HM ion contaminants from soil and aqueous media. For instance, pyrolyzed organic wastes have been reported to be good absorbents for immobilizing HMs like Cd, Pb, Cu, etc., in soils ( Ogunkunle et al. 2018).

Rice husk (RH) is the principal agricultural waste generated during rice processing worldwide. RH accounts for a momentous menace to the environment owing to the release of carbon dioxide (CO2) in surrounding areas where they are dumped and long-lasting smoke and methane produced from its open-air combustion (Sneh and Samadder 2014). Therefore, the use of RH by commercial industries is the alternative remedy to the disposal problem, due to easy availability and low cost (Oyetola and Abdullahi 2006).

This review article provides reports on the removal efficiency/potential of RH as an adsorbent and its applicability in various aspects. Several attempts have been made to harvest scientific information from several published studies relating to RH. Recently, the adsorption method for metal removal has gained much attention for its efficient treatment of wastewater through the low-cost adsorbent. Agricultural wastes are easily available, affordable, eco-friendly and have a high capacity for the adsorption of HMs (Sud et al. 2008). Agricultural junks had been employed for surface assimilation of heavy metals in the environment (Agbozu and Emoruwa 2014); RH used for the adsorption of Cu (Zhang et al. 2014); sawdust for Cu, Pb and Cd removal (Sciban and Klasnja 2003; Bulut and Tez 2007; Witek-Krowiak 2013); peanut husk for Cu, Zn and Mn removal (Oliveira et al. 2010); pigeon pea pod for removing Ni (Aravind et al. 2013); and tea wastes for removing Pb and Cu (Amarasinghe and Williams 2007) have been previously investigated.

Removal of HMs from soil medium was possible using agricultural wastes, such as the use of RH as adsorbent (Fig. 3). Plant wastes are of low cost and are easily available since they are perceived to be of little or no economic value. Using rice husks, sawdust, and maize cobs as low-cost adsorbents, Abdel-Ghani et al. (2007) have proved that rice husk can provide removal efficiency of ⁓98.15% for Pb at room temperature and proved to be effective adsorbents for several metal ions. Therefore, this review paper aims at providing information on the application of rice husks as a prospective absorbent for HMs elimination from contaminated aqueous and soil media.

Properties of rice husk

Rice husk (RH) is by-product biomass of rice processing constituting about ⁓ 20 wt% of bulk grain weight (Hossain et al. 2018). They are highly rich in silica with about 75–90% organic matter content. Table 1 presents the typical properties of RH according to Bronzeoak (2003).

Several applications of rice husk ash

Rice husk ash (RHA) is an amorphous silica produced from pyrolyzed RH at a certain temperature range (Katsuki et al. 2005). RHA has varying particle structures depending on pyrolysis temperature (Table 1) and the ecological origin of the rice. It is composed of 90% Si2O, 1.48% CaO. 1.23% MgO, 1.09% MnO, 1.54% Fe3 O3, and 1.21% Al2O3 (Rao et al. 2016). RHA is known to be useful in various industrial applications such as water purification, soil amendment, and fertilizers as well as in the steel, ceramics, and refractory industry. The suitability of RHA has been reported to strongly depend on the ash chemical composition which is predominantly silica in nature and was also confirmed to be senior to surrogate substances such as silica fume, fly ash, and slag (Agus et al. 2002). RHA has also been found useful in high-quality steel production. RHA has also been established to be useful as a quality insulator owing to its features such as high melting point, low thermal conductivity, high porosity, and low bulk density. RHA has also found application in the coating over of molten metal and steel in tun-dishes and ladles (Ahmed et al. 2008), thereby acting as a very good insulator and prevents too rapid cooling of metal and ensuring homogeneity in solidification during casting. Other applications of RHA are described below.

Admixture in the production of low-cost concretes

The presence of amorphous silica (85–95%) with high pozzolanic properties has made RHA a good candidate for cement replacement. Addition of RHA with lime and aggregates this will now follow by casting in preferred shape and sizes. Mixed proportion of RHA (binder) and some other admixtures in the ratio of 20% and 80% lime, close to 7 MPa strength, is achieved in two weeks. Amorphous RHA is reported to be more preferred in the manufacturing of concrete owing to its high pozzolanic property (Giddel and Jivani 2007).

Use in ceramics and refractory industry

Silica content of RHA in the amorphous form allows it to serve as non-heat conducting substance, which has found applications in the production of refractory bricks (Pal et al. 2012). Insulation refractories made from RHA are produced through the mixture of various flux contents serving as binders, plasticizers, and pore-forming agents to raise the porosity of the products (Bhardwaj and Majhi 2017; Sobroza et al. 2017). RHA serves as a source of silca during the production of cordierite. Giddel and Jivani (2007) reported that when kaolinite was replaced with RH silica in the mixture, cordierites yield was much higher at a reduced crystallizing temperature and also in decreased activation energy for crystallization.

Application of RHA in the production of silica

RHA has been reported as the most promising waste for the generation of silica (Hossain et al. 2018). The amorphous form of RHA features high silica content and this makes it an important candidate for a wide variety of applications in industries like chemicals, construction, electronics, and ceramics. Owing to huge silica content of RHA, the production of silica and subsequently silicon carbide and silicon nitride flour was economical (Adam et al. 2006). Silicon carbide is an important component in some engineering applications like ceramic and metal fabrications and other materials in the production of optic and electronic devices (Davidson and Regener 2000; Hossain et al. 2017). Soltani et al. (2015) highlighted the use of silica from RHA to manufacture non-oxide ceramics, nano-SiO2, and silicon. Giddel and Jivani (2007) also asserted increase demand for amorphous silica in the manufacture of high-grade cement and concrete for bridge construction and marine environments. Also, due to the high demand for highly purified nanosilica for many scientific applications (Wantala et al. 2012), RHA derived from combustion with either acid or alkali treatment has been proposed to increase the silica content to > 99 wt% (Hossain et al. 2018). A typical extraction procedure of silica from RHA is schematically presented in Fig. 4 as proposed by Zulkifli et al. (2013).

Insulation of fire bricks using RH

Owing to the presence of pores developed in RH when organic contents are burnt off during heating, it has found application in the production of bricks for better thermal insulation. The pores function as entrapment for air, thus enhancing its insulating features and making the brick structure a good insulation material (Agus et al. 2002).

Other uses of RH

RH as a common raw material has found utility in the production of ethanol, furfural, acetic acid, and xylitol. Literature also indicated that RH can be used as polishing agents in metal industries, fabrication of everlasting building materials, industrial raw materials, and so on. Recent advances have led to the manufacturing of composite materials such as RH-derived C/SiO2 composite (Hossain et al. 2017). The C/SiO2 appears to be the main component of the next generation of high-performance lithium-ion batteries (Wang et al. 2014).

Use of RH for the removal of HMs

Removal of HMs from aqueous media

These days, risky overwhelming metal pollution of wastewater is posing serious environmental concerns globally owing to increase urbanization and industrialization; for example, As3+/AS5+, Pb2+, Cd2+, Ni+, Cr3+/Cr6+, Zn2+, Cu2+, Hg+/Hg2+, Co2+, etc., contained in wastewater are progressively legitimately or in a roundabout way released into water bodies especially in creating countries (Jiang et al. 2009). Moreover, the dirt encompassing army installations offer a potential danger of certain overwhelming metals, which can be a risk to groundwater and surface water (Joseph et al. 2015). Figure 5 describes several causes of heavy metal toxicity. Characteristically, these overwhelming metal particles are not biodegradable and will in general effectively gather in living organisms. Although taking in a few amounts of various heavy metals is very important for individuals because of their quality for certain nutrients or co-factors, unnecessary introduction or admission can have hazardous results. Furthermore, a great deal of physical and mental hindrance, for example, queasiness, spewing, looseness of the bowels, asthma, pneumonia, skin degeneration, kidney and liver glitch, inborn variations from the norm, weight reduction, and different tumors, can be the consequence of heavy metals found in industrial wastewater (Ray and Shipley 2015). Fabrication of a cost-effective, eco-friendly, nontoxic adsorbent is required to remove these HMs from contaminated soil. Keeping the above point in view, researchers and scientists have exploited rice husk in several ways as an alternative material suitable for the removal of HMs from polluted soil. A few of them are briefly reviewed in this section.

Srivastava et al. (2008) worked on the adsorption of Cd2+ and Zn2+ ions from binary systems using RHA. In their findings, the prime pH for the removal of subject metals was found to be 6.0. It was established from the studies that Zn2+ ions were absorbed more than Cd2+ ions. It was also found that there was equilibrium metal removal decline following any increase in the concentration of the counterpart metal ion as the combined effect of Cd2+ and Zn2+ ions on RHA is usually seen to be non-complementary. Remediation of Zn2+ and Hg2+ from the water on a carbonaceous sorbent that was chemically prepared from RH has been carried out by El-Shafey et al. 2010. In a similar vein, rice husk has been used to eliminate heavy metals ions Fe2+, Pb2+, Ni2+, Cd2+ and Cu2+ from wastewater of electroplating industries. Results reveal that this low-cost adsorbent can be successfully used for the removal of HMs with a concentration level ranging from 20 to 60 mg/l. The level of removal of heavy metal ions was based on the dose of low-cost adsorbent and adsorbent concentration (Hegazi et al. 2013).

Rice husk was used to adsorb Zn2+ and Pb2+ ions to remove the metals ions in dairy wastewater using the batch method. Adsorbent dose, contact time, and pH value of wastewater were the factors influencing Zn2+ and Pb2+ ions sorption. The maximum adsorption capacity of the adsorbent for Zn2+ and Pb2+ ions was found to be 19.617 and 0.6216 mg/g, and the maximum percent adsorption of Zn2+ and Pb2+ ions was found to be 70% and 96.8% (Elham et al. 2010). Gupta et al. (2007) worked on the removal of HMs, i.e., Cu2+, Pb2+, and Zn2+ using low-cost hybrid precursor fabricated from rice husk. The high adsorption capacity of 90% was achieved. Ajmal et al. (2003) reported that adsorption of Ni2+ and Cd.2+ was higher when PRH was used as adsorbent. It was also reported that an adsorption rate of more than 90% was obtained at a pH value of 12. The mechanism for adsorption involves surface phenomenon, where an adsorbate adsorbs on the active sites of an adsorbent. The schematic diagram for the adsorption is provided in Fig. 6

Removal of HMs from soil

Rice husk dust has been found useful for the improvement of soil properties. In an experiment by Uguru et al. (2015) to examine the effects of RH dust on soil properties such as the distribution of particle size, total porosity, bulk density, hydraulic conductivity, and subsequent influence the yield of maize in Abakaliki, South-Eastern Nigeria, the authors found out that there was a noticeable increase in soil properties like the total porosity, hydraulic conductivity, and grain yield. It was also observed that the non-pyrolyzed RH dust greatly improved the soil properties when compared to pyrolyzed RH dust, and the improvement was RH dust dose dependent. The authors recommended that RH dust should be utilized as a form of soil amendments.

In a similar study, Amponsem et al. (2017) subjected soil samples from an e-waste dumpsite in Accra, Ghana, to amendments using RH at rates of 20%, 40%, and 60% w/w in separate rubber containers for 21 days. The authors reported that the RH application minimized the concentrations of Cu, Fe, and Zn in the e-waste dumpsite soil. Also, it was found that 97% RH amendment showed high adsorption for Cu in relation to Zn and Fe and that the more the RH dose, the higher the adsorption capacity. Amponsem et al. (2017) confirmed, through the outcome of the study, that RH is a highly suitable bio-adsorbent for metal ions in soils with great potential as components for remediation and soil fertility management.

Conclusion

Over the years, there has been lackadaisical attitude toward environmental laws and thus there is need for an improved quality treatment for the removal of hazardous materials and metal ions from the environment in other to protect the human health and aquatics life. Recently, different adsorbent has been fabricated by various agricultural waste products. However, rice husk-base adsorbent, rice husk ash-derived silica, and untreated rice husk can be used efficiently for the elimination of toxic metals from water and soil owing to their unique characteristics. Rice husks are good remediation substances as they can easily be produced, environmental friendly during their usage, cost-effective, low cost, simple regeneration and reusability for a better environmental sustainability.

References

Abdel-Ghani NT, Elchaghaby GA (2007) Influence of operating conditions on the removal of Cu, Zn, Cd, and Pb ions from wastewater by adsorption. Int J Environ Sci Tech 4(4):451–456

Adam F, Balakrishnan S, Wong P (2006) Rice husk ash silica as a support material for ruthenium-based heterogeneous catalysts. J Phys Sci 17(2):1–3

Agbozu IE, Emoruwa FO (2014) Batch adsorption of heavy metals (Cu, Pb, Fe, Cr, and Cd) from aqueous solutions using coconut husk. Afr J Environ Sci Technol 8(4):239–246

Agu SM (2002) Utilization of uncontrolled burnt rice husk ash in soil improvement. Dimensi Teknik Sipil 4(2):100–105

Ahmed YMZ, Ewaisem EM, Zaki ZI (2008) Production of porous silica by the combustion of rice husk ash for Tundish lining. J Univ Sci Technol Beijing 15(3):307–313

Ajmal M, Rao RA, Anwar S, Ahmad J, Ahmad R (2003) Adsorption studies on rice husk: removal and recovery of Cd (II) from wastewater. Biores Technol 86(2):147–149

Amarasinghe P, Williams RA (2007) Tea waste as a low-cost adsorbent for the removal of Cu and Pb from wastewater. Chem Eng J 132(1–3):299–309

Amponsem J, Dali GLA, Ojeh VN (2017) Rice husk for the removal of heavy metals from polluted soils at the Agbogbloshie e-waste dumpsite in Accra Ghana. SF J Glob Warm 2017(1):1

Aravind J, Muthusamy S, Sunderraj SH, Chandran L, Palanisamy K (2013) Pigeon pea (Cajanus cajan) pod as a novel eco-friendly biosorbents: a study on equilibrium and kinetics of Ni(II) biosorption. Int J Ind Chem. https://doi.org/10.1186/2228-5547-4-25

Basheeru KA, Okoro HK, Adekola FA, Abdus-Salam N (2020) Speciation & quantification of organotin compounds in Lagos harbor Nigeria. Int J Environ Anal Chem. https://doi.org/10.1080/03067319.2020.1849647

Basheeru KA, Okoro HK, Adekola FA, Abdus-Salam N (2021) Mobility and sequential extraction of potentially toxic elements in sediment of Lagos lagoon. Chem Afr 4:411–427. https://doi.org/10.1007/s42250-020-00218-4

BhardwajHossain ASKS, Majhi MR (2017) Preparation and characterization of clay bonded high strength silica refractory by utilizing agriculture waste. Bol Soc Esp Cerám Vidr 56:256–262

Bronzeoak Ltd (2003) Rice husk ash market study. EXP 129, DTI/Pub URN. 03/668.

Bulut Y, Tez Z (2007) Removal of heavy metals from aqueous solution by sawdust adsorption. J Environ Sci 19(2):160–166

Davidson A, Regener D (2000) A comparison of aluminium-based metal-matrix composites reinforced with coated and uncoated particulate silicon carbide. Compos Sci Technol 60:865–869

Elham A, Hossein T, Mahnoosh H (2010) Removal of Zn (II) and Pb (II) ions using rice husk in food industrial wastewater. J Appl Sci Environ Manag 14(4):159–162

El-Shafey EI (2010) Removal of Zn(II) and Hg(II) from aqueous solution on a carbonaceous sorbent chemically prepared from rice husk. J Hazard Mater 175:319–327

Giddel MR, Jivan AP (2007) Waste to Wealth, Potential of Rice Husk in India a Literature Review. International conference on cleaner technologies and environmental management PEC, Pondicherry, India.

Gupta N, Mandloi D, Amritphale SS, Chandra N, Sikarwar A (2007) J Environ Res Dev 1(4):357–364

Hegazi HA (2013) Removal of heavy metals from wastewater using agricultural and industrial wastes as absorbents. Hous Build Natl Res Centre J 9(3):276–282

Hossain SK, Mathur L, Roy PK (2018) Rice husk/rice husk ash as an alternative source of silica in ceramics: a review. J Asian Ceram Soc 6(4):299–313

Infotox CC (2000) Environmental health risk assessment - methyleyclopentadienyl manganese tricarbonyl (mmt) as an automotive performance enhancer in petrol in South Africa. Document No 009–2000. Final Report 7

Jiang Y, Pang H, Liao B (2009) Removal of copper (II) ions from aqueous solution by modified bagasse. J Hazard Mater 164(1):1–9

Joseph T, Dubey B, McBean EA (2015) Human health risk assessment from arsenic exposures in Bangladesh. Sci Total Environ 15(527–528):552–560

Katsuki H, Furuta S, Watari T, Komarneni S (2005) ZSM-5 zeolite/porous carbon composite: conventional- and microwave-hydrothermal synthesis from carbonized rice husk. Micropor Mesopor Mater 86(1–3):145–151

Ogunkunle CO, Varum M, Ogundele IG, Olorunmaiye KS, Paul MS (2018) Citrus epicarp-derived biochar reduced Cd uptake and ameliorates oxidative stress in young Abelmoschus esculentus (L) Moench (okra) under low Cd stress. Bull Environ Contam Toxicol 100(6):827–833

Okoro HK, Fatoki OS, Adekola FA, Ximba BJ, Synman RG (2012) A review of sequential extraction procedures for heavy metals speciation in soil & sediments. Open Access Sci Rep 1(3):1–9

Okoro HK, Fatoki OS, Adekola FA, Ximba BJ, Synman RG (2014) Fractionation, mobility and multivariate statistical evaluation of metals in marine sediments of cape town Harbor, South Africa. Chem Speciat Bioavailab 26(126):138

Okoro HK, Ige JO, Iyiola OA, Ngila CJ (2017) Fractionation Profile, mobility pattern and correlations of heavy metals in estuary sediments from Olonkoro River in Tede catchment of western region, Nigeria. Environ Nano Technol Monit Manag 8:53–62

Okoro HK, Ige JO, Ngila CJ (2018) Characterization and evaluation of heavy metals pollution in river sediments from south western Nigeria. J Kenya Chem Soc 11(1):18–27

Oliveira FD, Soares AC, Freitas O, Figueiredo SA (2010) Copper, nickel, and zinc removal by peanut hulls: batch and column studies in mono, tri-component systems, and with real effluent. Glob Nest J 12(20):206–214

Oyetola EB, Abdullahi M (2006) The use of rice husk ash in low-cost concrete block production. Leonardo Electron J Pract Technol 8:58–70

Pal AR, Bharati S, Krishna NVS, Das PG (2012) The effect of sintering behavior and phase transformations on the strength and thermal conductivity of disposable tundish linings with varying compositions. Ceram Int 38:3383–3389

Panagos P, Van Liedekerke M, Yigini Y, Montanarella L (2013) Contaminated sites in Europe: a review of the current situation based on data collected through a European network. J Environ Public Health. https://doi.org/10.1155/2013/158764

Ray PZ, Shipley HJ (2015) Inorganic nano-adsorbents for the removal of heavy metals and arsenic: a review. RSC Adv 5:29885–29907

Sciban M, Klasnja M (2003) Optimization of usage of wood sawdust as adsorbent of heavy metal ions from water. ISIRR 3:51–56

Sneh L, Samadder SR (2014) Removal of heavy metals using rice husk: a review. Int J Environ Res Develop 4:165–170

Sobrosa FZ, Stochero NP, Marangon E, Tier MD (2017) Development of refractory ceramics from residual silica derived from rice husk ash. Ceram Int 43:7142–7146

Soltani N, Bahrami A, Pech-Canul MI, Gonzalez LA (2015) Review the physicochemical treatments of rice husk for the production of advanced materials. Chem Eng J 264:899–935

Srivastava VC, Mall ID, Mishra I (2008) Removal of cadmium (II) and zinc (II) metal ions from binary aqueous solution by rice husk ash. Colloids Surf A Physicochem Eng Asp 312(2–3):172–184

Sud D, Mahajan G, Kaur MP (2008) Agricultural waste material as potential adsorbent for sequestering heavy metal ions from aqueous solutions–a review. Biores Technol 99(14):6017–6027

Toth G, Hermann T, Da Silva MR, Montanarella L (2016) Heavy metals in agricultural soils of the European union with implications for food safety. Environ Int 88:299–309

Uguru BN, Mbah CN, Njoku C (2015) Effect of rice husk dust on selected soil physical properties and maize grain yield in Abakaliki, south eastern Nigeria. Glob Adv Res J Agric Sci 4(12):878–886

Wang X, Zhou QX (2004) The ecological process, effect, and remediation of heavy metals contaminated soil. Ecol Sci 23(3):278–281

Wang L, Xue J, Gao B, Gao P, Mou C, Li J (2014) Rice husk derived carbon-silica composites as anodes for lithium-ion batteries. RSC Adv 4:64744–64746

Wantala K, Khongkasem E, Khlongkarnpanich N, Sthiannopkao S, Kim KW (2012) Optimization of As (V) adsorption on Fe-RHMCM-41-immobilized GAC using Box-Behnken design: effects of pH, loadings, and initial concentrations. Appl Geochem 27:1027–1034

Witek-Krowiak A (2013) Application of beech sawdust for removal of heavy metals from water: biosorption and desorption studies. Eur J Wood Wood Prod 71(2):227–236

Zhang Y, Zheng R, Zhao J, Ma F, Zhang Y, Meng Q (2014) Characterization of H3PO2- treated rice husk adsorbent and adsorption of Cu(II) from aqueous solution. Biomed Res Int. https://doi.org/10.1155/2014/496878

Acknowledgements

The corresponding author, Dr. H.K. Okoro, and other coauthors thank the University of Ilorin, Ilorin, Nigeria and the University of Johannesburg, SouthAfrica, for making available library database and laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Ethical approval

All authors agreed to the submission of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Okoro, H.K., Alao, S.M., Pandey, S. et al. Recent potential application of rice husk as an eco-friendly adsorbent for removal of heavy metals. Appl Water Sci 12, 259 (2022). https://doi.org/10.1007/s13201-022-01778-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01778-1