Abstract

In this work the efficiency of applying non-modified beech sawdust for the removal of Cu2+ and Cr3+ heavy metal ions from water solutions was examined. Parameters taken into consideration in the analysis of environment conditions were influence of sorbent concentration, initial concentration of metal ions, temperature effect, presence of additional substances in solution (NaCl and MgCl2 inorganic salts and anionic and cationic surface-active compounds). Results of kinetic experiments were described by two models: pseudo-first-order and pseudo-second-order; equilibrium results were approximated with five non-linear isotherm models. Maximum sorption capacity at a temperature of 20 °C and pH 5.0 was 30.22 mg g−1 for Cu2+ ions and 41.86 mg g−1 for Cr3+ ions. The positive value of the thermodynamic parameter ΔH° indicates the endothermic nature of the process. Application of 0.1 M HCl as the eluent enables effective desorption of precious metals and reuse of sorbent for purifying water solutions of Cu2+ and Cr3+ ions.

Zusammenfassung

In dieser Arbeit wird die Anwendbarkeit von nicht modifiziertem Buchensägemehl zur Entfernung von Cu2+ und Cr3+ Schwermetallionen aus wässrigen Lösungen untersucht. Untersucht wurden der Einfluss der Sorbentkonzentration, der anfänglichen Konzentration von Metallionen, der Temperatur sowie vorhandener zusätzlicher Substanzen in der Lösung (NaCl und MgCl2, anorganische Salze sowie anionische und kationische oberflächenaktive Verbindungen). Die Ergebnisse der kinetischen Experimente wurden mit zwei Modellen, einem Modell pseudo-erster Ordnung und einem Modell pseudo-zweiter Ordnung, beschrieben. Die Ergebnisse der Gleichgewichtsuntersuchungen wurden durch fünf nicht-lineare Isothermen Modellen beschrieben. Die maximale Sorptionskapazität bei einer Temperatur von 20 °C und einem pH-Wert von 5.0 war 30,22 mg g−1 für Cu2+-Ionen und 41,86 mg g−1 für Cr3+ Ionen. Der positive Wert des thermodynamischen Parameters ΔH° deutet auf einen endothermen Charakter des Prozesses hin. Die Anwendung von 0,1 M HCl als Eluent ermöglicht eine effektive Desorption von Edelmetallen und die Wiederverwendung der Sorbenten zur Reinigung wässriger Lösungen von Cu2+ und Cr3+ Ionen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Heavy metals are one of the most dangerous environmental pollution. They are a menace for both the people and the whole ecosystem due to their toxicity and mutagenic, immunogenic, carcinogenic, teratogenic action. Metals accumulate very easily in living organisms that is why their harmful effect may appear even at very low concentrations. Main anthropogenic sources of metals are: power plants, extractive industry and metal ores processing, metallurgical industry, chemical, electronic, nuclear industry, agriculture and waste disposal. Heavy metals water pollution presents a significant environmental problem requiring immediate intervention.

Currently, in modern technologies new materials for production are intensively searched for and attempts are made to eliminate chemicals harmful to the environment. Special emphasis is put on reusing raw materials, replacing undegradable substances by degradable ones, using biological methods in industry and decreasing waste water generation in production processes. Application of known and tested methods for the removal of metal ions from water on industrial scale is often unreal from an economic point of view. It is especially seen during necessity of purifying large water reservoirs containing most often very diluted elements. Conventional methods of removal of heavy metals from solutions, such as ion exchange, chemical oxidation/reduction, filtration, electrochemical methods, precipitation and membrane technologies may often be ineffective or uneconomic, especially in the case of low metal concentration in solution (within the range of 1–100 mg L−1).

In this context, there is the necessity of developing new separation methods which would be simultaneously effective and selective. One of the methods used for metal ions removal is adsorption on various sorbents, for example, on active carbon (Šváb et al. 2011). But its main disadvantage is the high cost of sorbents. That is why searches for still new, more effective methods, cheaper materials for sorbents production, i.e., of biological origin (Witek-Krowiak and Reddy 2013), commonly occurring or from industrial wastes, are undertaken. Many various waste materials are tested, such as: fragmented coconut shells (Amuda et al. 2007), fruit rinds (Schiewer and Patil 2008), lignocellulosic materials (Reddy et al. 2012) or animal waste (An et al. 2001). Extremely low prices of those sorbents and possibility of their regeneration make the biosorption process economically profitable and highly competitive to other methods of metals removal from water.

Many materials of plant origin, waste in building industry (mainly sawmill waste) are problems because they must be disposed. There were propositions to use them for adsorption of various contaminants, both organic [dyes (Ofomaja and Ho 2008), herbicides (Nanseu-Njiki et al. 2010), phenols (Ofomaja and Unuabonah 2011; Ofomaja 2011), humic acids (Kamari et al. 2009)] and inorganic, i.e. heavy metal ions (Hansen et al. 2010; Ofomaja 2010; Rahman and Islam 2009; Andrabi 2011). If it was possible to use sawdust as adsorbent of contaminants from industrial waste water, it would solve simultaneously two problems, both waste disposal and purifying waste water of heavy metals to desired limits. So far literature studies focused mainly on application of oak (Rahman and Islam 2009) and maple sawdust (Sciban et al. 2006a) for removal of various heavy metals (mainly Cu2+, Pb2+, Zn2+) from water solutions. There are not many reports (Hansen et al. 2010) on removing heavy metal ions (especially Cu2+, Cr3+) through beech sawdust and the influence of process parameters upon biosorption.

The aim of this work was application of waste materials of plant origin (beech sawdust) without initial preparation (no chemical modifications) for sorption of heavy metals (Cu2+, Cr3+) from water solutions. This work focuses on (1) determination of balance and kinetic parameters of biosorption process, (2) determination of process conditions impact upon biosorption, especially concerning those conditions, which are very important in working with real waste water and simultaneously which have rarely been examined so far in available literature concerning biosorption (i.e., influence of salinity, influence of adding surface-active agents), (3) testing of the efficiency of heavy metals desorption and reuse of sorbent.

2 Materials and methods

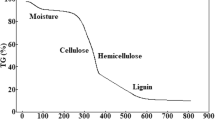

2.1 Sorbent characteristic

Beech sawdust was collected from a local sawmill and used without prior modification. Samples of beech sawdust were sieved to different mesh sizes. Fractions between 200 and 270 mesh (0.053–0.075 m) were used in the experiments.

pHzpc (point of zero charge) was determined using a method available in literature (Wan Ngah and Hanafiah 2008). pHzpc of sawdust was 4.32. For pH higher than pHzpc sorbent surface has negative charge, for lower pH than pHzpc the charge is positive. It was decided to carry out experiments with pH 5.0.

2.2 Preparation of aqueous metal ions solutions

Solutions of Cu2+ and Cr3+ ions were prepared by dissolving predefined amounts of CuSO4 and Cr(NO3)3 in distilled water to achieve concentrations of 1,000 mg L−1 in each flask. Different initial concentrations of metal ions were prepared by diluting the stock solution. The pH of the solutions was adjusted using 0.1 N HCl and 0.1 N NaOH to achieve the desired values.

2.3 Effect of contact time

Kinetic studies were carried out in order to determine the contact time required for the biosorbent to reach the equilibrium with the adsorbed metal ions. 200 mL samples of 20–200 mg L−1 metal ion solutions at specified concentration were prepared and mixed with specified amounts of the sorbent (1.0 g). The experiments were carried out at pH 5.0. Sorption processes were carried out in flasks placed in a thermostatic water-bath shaker at fixed temperature until equilibrium was reached. 3 mL samples were collected at specified intervals for the analysis of metal concentrations. Concentrations of metal ions in samples were determined by atomic absorption spectroscopy (AAS). The amounts of metal ions sorbed on the biosorbent phase (q t , mg g−1) were calculated from the following expression (Eq. 1):

where C 0 and C t are the initial metal ion concentration and concentration at defined time (mg L−1), V is the solution volume (L) and m is the mass of the biosorbent (g).

2.4 Equilibrium experiments

Sorption equilibrium experiments were carried out in a batch mode. 100 mL of metal sample solutions at predetermined concentrations (10–500 mg L−1) were transferred to 250 mL Erlenmeyer flasks placed in a thermostatic water-bath shaker at fixed temperature. The sorbent (0.2 g) was added to the solutions. The experiments were carried out at pH 5.0. After 2 h, the solutions were centrifuged and the metal ions concentrations in the supernatant were determined.

2.5 Effect of process parameters

The effect of the initial metal ions concentration (20–200 mg L−1) was tested with a fixed amount of the sorbent (5 g L−1). The effect of the adsorbent dosage was studied for the initial metal ions concentrations of 20 mg L−1 with various sorbent dosages (0.5; 1.0; 2.5; 5.0; 10.0; and 20.0 g L−1). The effect of temperature was studied at temperature range 20–50 °C. The effect of salts addition (NaCl, MgCl2, obtained from POCh, Poland) on the amount of adsorbed metal ions was analyzed over the salt concentration 0–5 % (w/w). Effect of surfactants presence in the solution was studied with various initial anionic (sodium dodecyl benzene sulphonate, SDBS, obtained from Sigma-Aldrich) and cationic (cetyltrimethylammonium bromide, CTAB, obtained from Sigma-Aldrich) surfactant concentrations (in the range of 0–3 CMC). The critical micelle concentration value (CMC) was 2 and 0.8 mM for SDBS and CTAB, respectively.

2.6 Desorption

In order to consider the practical usefulness of the biosorbent, desorption experiments were performed. After the biosorption test, 0.2 g of metal-loaded sorbent was stirred in 100 mL of the following solutions: distilled water, 0.1 M HCl, 0.1 M HNO3, 0.1 M EDTA. After 60 min of agitation, the metal concentration in the solution was determined. For the best eluent, the biosorption and desorption steps were repeated four times.

All of the experiments were carried out in duplicate and the average values were used in the calculations. The maximum deviation was found to be ±2 %. All model parameters were evaluated by non-linear regression using OriginPro8 software. In this study, commonly used error functions, i.e., the correlation coefficient (R 2) and the Chi square (χ 2), were examined for each set of experimental data.

3 Results and discussion

3.1 Biosorption kinetics

Biosorption kinetics describes change of metal ions concentration during the process until equilibrium was attained. Initial concentrations of metal ions during the experiment were 20–200 mg L−1, biosorbent concentration was constant and its value was 5 g L−1. Experiment was carried out at room temperature and pH 5. In the course of time, the concentration of metal ions in the solution decreased, because more and more active places on the biosorbent surface were filled. State of equilibrium established very quickly after ca. 20 min both for Cu2+ ions (Fig. 1a) and Cr3+ ions (Fig. 1b). Biosorption kinetics is of two-stage nature. At the beginning, biosorption proceeds very fast, which is connected to the great accessibility of the non-filled active places. Second stage of concentration change leads to establishing the state of equilibrium, it is slower and concentrations change insignificantly.

Biosorption of heavy metals on beech sawdust (biosorbent concentration—5 g L−1, initial heavy metal concentration 20–200 mg L−1, temperature 20 °C, pH 5) a Cu2+, b Cr3+

Biosorption von Schwermetallen an Buchensägemehl (Biosorbentkonzentration—5 g L−1, ursprüngliche Schwermetallkonzentration 20–200 mg L−1, Temperatur 20 °C, pH 5) a Cu2+, b Cr3+

Biosorption kinetics are described with two models: pseudo-first-order (Lagergren and Sven 1898) and pseudo-second-order (Ho 2006) (Table 1). Interpreting data contained in Table 1, it may be stated that the pseudo-second-order model which best describes the biosorption process for both metal ions. R 2 values for concentrations of 20–200 mg L−1 were >0.994. The pseudo-first-order model also describes well experimental points, but correlation coefficients are somewhat lower (>0.986) and χ 2 values are higher than for the pseudo-second-order model. Increase in heavy metal ions initial concentration results in significant increase in the sorption capacity. For Cu2+ ions, the value changes from 4.006 to 22.55 mg g−1, for Cr3+ ions—from 3.965 to 30.38 mg g−1. Increase in metal ions initial concentration is equal to increase of driving force of the entire process (difference of concentrations in solution and at sorbent surface), which significantly increases the process efficiency. Kinetic parameters are reduced with increasing sorbate concentration from 20 to 200 mg L−1 (from 2.738 to 0.024 g mg−1 min−1, for Cr3+ ions—from 0.508 to 0.014 g mg−1 min−1), probably as a result of limited diffusion at the sorbent surface and in its pores.

3.2 Biosorption equilibrium

Initial concentrations of heavy metal ions were within the range of 10-500 mg L−1. Biosorbent concentration was 2 g L−1. Experiment was carried out at room temperature and pH 5. Obtained results are shown in Table 2. For the determination of equilibrium isotherms Langmuir, Freundlich, Temkin, Redlich-Peterson and Sips (Witek–Krowiak et al. 2011) models were applied.

Langmuir–Freundlich (Sips) model was best fitted to the experimental points with high correlation coefficients (>0.997) and low χ 2 values (0.76 and 0.580). Also the model of Langmuir and Redlich-Peterson describes very well the results of the experiment. High correlation coefficients (over 0.994) and low values of the parameter χ 2 (<0.900) were obtained, which confirms the good convergence of models with the points. Temkin and Freundlich models do not reflect well the equilibrium biosorption of heavy metals on the studied sorbent. Obtained R 2 values were low (<0.990), moreover, values of the function χ 2 were very high which confirms the poor fit of these models to the experimental points. This graph is also a confirmation of better matching of Langmuir, Redlich-Peterson and Spis functions to the research results.

Sorption capacities of wooden sawdust available in literature (Table 3) were compared in regard to Cu2+ ions. For Cr3+ ions only one literature item about biosorption on sawdust was found, that is why values for other waste sorbents were compared. Values obtained as results of the experiments shown in this publication are relatively high compared to other sorbents. It is worth to emphasize that sorbent used in this work has not been modified chemically and may successfully compete with other sorptive materials (Blázquez et al. 2011; Lugo–Lugo et al. 2012).

3.3 Sorbent concentration impact

The quantity of used biosorbent is an important parameter influencing sorption process, because it is responsible for the amount of groups on the surface that are able to bind heavy metals under given process conditions. Figure 2 shows the sorption capacity profile versus biosorbent concentration within a range of 0.5–20 g L−1. A significant increase in sorption capacity together with an increase in sorbent concentration was observed, this relation is connected to the occurring larger number of groups able to bind heavy metals and thereby to increase efficiency of solutions purification. Maximum saturation is observed for sorbent concentration of 5 g L−1, increasing the amount of sorbent does not result in an increase in process efficiency such significant, when sorbent is able do adsorb most of ions from the solution Fig. 3.

3.4 Influence of temperature and process thermodynamics

Temperature is one of the most important parameters influencing biosorption process. Figure 4 and Table 4 describe the influence of temperature upon biosorption equilibrium within the temperature range 20–50 °C. In case of both heavy metals an increase of sorption capacity (from 30.22 to 36.04 mg g−1 for Cu2+ ions and from 41.86 to 50.04 mg g−1 for Cr3+ ions) and coefficient b L of Langmuir equation (from 0.087 to 0.221 L mg−1 for Cu2+ ions and from 0.340 to 0.835 L mg−1 for Cr3+ ions) is observed. That may be caused by higher mobility of heavy metal ions at higher temperatures, which is connected to their larger kinetic energy.

Adsorption mechanism may be examined by calculation of thermodynamic parameters such as change of Gibbs free energy, (ΔG°), enthalpy (ΔH°) and entropy (ΔS°), calculated on the base of the relationship presented—Eq. (2):

where, R is the universal gas constant (8.314 J mol−1 K−1), T is temperature (K) and K 0 (L mol−1) is the equilibrium coefficient. Values of enthalpy and entropy may be calculated from the relationship by drawing the graph of dependence of natural logarithm of K 0 on 1/T.

Calculated thermodynamic parameters are shown in Table 5. Negative values of free energy suggest that the process is feasible and spontaneous. Increase of negative value of ΔG° together with temperature increase suggests that the process is more spontaneous at higher temperatures. Positive value of ΔH° (23.98 and 22.15 kJ mol−1 for copper and chromium ions) indicates endothermic nature of adsorption process within the range of investigated temperatures (20–50 °C). ΔH° values obtained in the experiment indicate the mechanism of chemical sorption of investigated heavy metal ions on beech sawdust. Value of enthalpy within the range 2.1–20.9 kJ mol−1 indicates physical sorption, values over 20.9 kJ mol−1 indicates chemisorption (Ahmet and Mustafa 2008). Positive value of ΔS° entropy in both cases indicates increase in degree of freedom on the sorbent surface during adsorption of heavy metal ions.

3.5 Influence of salt presence

Effect of Na(I) and Mg(II) on the removal of Cu2+ and Cr3+ from aqueous solution by beech sawdust was studied using the inorganic salts NaCl, MgCl2 and the results are presented in Fig. 5. It was noticed that the presence of salts in the solution insignificantly decreases sorption ability of beech sawdust, especially in high concentrations of salts (above 3 %). Na+ and Mg2+ cations compete in the solution with heavy metal ions for binding places on sorbent surface. The presence of Na(I) and Mg(II) ions caused a decrease in sawdust biosorption efficiency, which was 5.6 % (Na+) and 3.5 % (Mg2+) in case of Cu(II) and 6.7 % (Na+) and 3.4 % (Mg2+) for Cr(III). Within concentrations range of 3–5 %, efficiency decrease is for Cu2+ ions, correspondingly, 7.1 and 7.3 % in the presence of NaCl and MgCl2, for Cr3+ ions the decrease was 12.7 and 8.7 %. It was observed that the presence of Na(I) caused a higher decrease in sorption capacity compared to Mg(II). This could be hypothesized as, the smaller ionic size monovalent sodium cations will easily adsorb onto the biomass surface compared with divalent magnesium ions. Despite a decrease in efficiency of biosorption in the presence of the salts, the sorbent potential is still high and it may still efficiently remove heavy metals from water solutions.

3.6 Influence of surface-active agents

Waste water containing heavy metals often also contain various organic compounds, especially surface-active compounds. At that stage of research the influence of the presence of anionic (example of SDBS) and cationic (example of CTAB) surfactants upon the process of Cu2+ and Cr3+ ions biosorption on beech sawdust was tested (Fig. 6).

SDBS particles may adsorb on hydrophobic sorbent surface, constituting additional places of cation binding. At below 1CMC (2 mM) SDBS concentration, the presence of surfactant in solution slightly improved the biosorption efficiency of sawdust. This is due to the molecules of SDBS may influence the biosorbent and produce additional binding sites for heavy metal ions. Values above critical micellar concentration (1 CMC) creation of micellar structures in solutions occur that have the ability of adsorbing metal ions on their surfaces and thereby disable its sorption on sorbent surface (Aksu et al. 2010; Witek-Krowiak et al. 2010). This results in a higher decrease in biosorption efficiency, up to 5.1 and 11.8 % and in cases of Cu2+ and Cr3+ ions. The presence of cationic surfactant (CTAB) in solution caused higher decrease of biosorption efficiency (12.3 and 33.8 % of Cu2+ and Cr3+ ions). Cationic surfactant molecules adsorbed on sorbent surface could repel positively charged heavy metal ions which caused decrease of efficiency of removing them from the solution. However, concentrations of surface-active compounds in waste water are not that high and application of biosorption for purifying waste water of heavy metal ions is possible even with the presence of surfactants.

3.7 Desorption

Desorption is an important issue, because it enables reusing sorbent in process and recovering of valuable heavy metals. Usually, various chelating agents (i.e. EDTA), acids, bases are used as eluting agents. In this work the efficiency of four eluents (distilled water, 0.1 M HCl, 0.1 M HNO3, 0.1 M EDTA) (Table 6) was tested. The largest recovery of heavy metals was obtained for 0.1 M HCl (over 97 %) and also for 0.1 M HNO3 (over 95 %). Chelating agent EDTA occurred to be less efficient (recovery 71–75 %). Desorption using distilled water was almost neglected.

In order to test the possibility of reusing given sorbent, four sorption–desorption measurement cycles using 0.1 M HCl as eluent were performed (Fig. 7). In all sorbent-metal ion pairs an insignificant decrease in sorption ability was observed after each cycle (within 5–10 % boundaries). Decrease of sorption ability may be caused by interaction of metal ions with functional groups, which may result in irreversible masking of active places on sorbent surfaces. However, after four cycles the decrease of the efficiency did not exceed 30 % which is a very good result and indicates that beech sawdust may be a suitable sorbent for removing heavy metal ions from water solutions.

4 Conclusion

Beech sawdust is a potential sorbent of heavy metals (Cu2+, Cr3+). The equilibrium is described best by Langmuir model, maximum sorption capacity at pH 5 and a temperature of 20 °C for beech sawdust was 30.22 mg g−1 for Cu2+ ions and 41.86 mg g−1 for Cr3+ ions. Biosorption of heavy metals is a process strongly related to temperature. Determined thermodynamic parameters suggest that in the case of that sorbent and those heavy metals, spontaneous and endothermic processes are involved. Despite the decrease in efficiency of biosorption in the presence of inorganic salts (NaCl and MgCl2) and organic compounds (cationic and anionic surface-active compounds, CTAB and SDBS), the sorbent potential is still high and it may still efficiently remove heavy metals from water solutions. HCl occurred to be a good agent enabling desorption of heavy metal ions from biosorbent surface, enabling reusing it in consecutive sorption–desorption cycles with little loss of sorption capacity.

References

Acar FN, Eren Z (2006) Removal of Cu(II) ions by activated poplar sawdust (Samsun Clone) from aqueous solutions. J Hazard Mater 137:909–914

Ahmet S, Mustafa T (2008) Biosorption of total chromium from aqueous solution by red algae (Ceramium virgatum): equilibrium, kinetic and thermodynamic studies. J Hazard Mater 160:349–355

Aksu Z, Ertugrul S, Dönmez G (2010) Methylene blue biosorption by Rhizopus arrhizus: effect of SDS (sodium dodecylsulfate) surfactant on biosorption properties. Chem Eng J 158:474–481

Amuda OS, Giwa AA, Bello IA (2007) Removal of heavy metal from industrial wastewater using modified activated coconut shell carbon. Biochem Eng J 36:174–181

An HK, Park BY, Kim DS (2001) Crab shell for the removal of heavy metals from aqueous solution. Water Res 35:3551–3556

Andrabi SMA (2011) Sawdust of lam tree (Cordia africana) as a low–cost, sustainable and easily available adsorbent for the removal of toxic metals like Pb(II) and Ni(II) from aqueous solution. Eur J Wood Prod 69:75–83

Batista APS, Romão LPC, Arguelho MLPM, Garcia CAB, Alves JPH, Passos EA (2009) Biosorption of Cr(III) using in natura and chemically treated tropical peats. J Hazard Mater 163:517–523

Blázquez G, Martín-Lara MA, Dionisio-Ruiz E, Tenorio G, Calero M (2011) Evaluation and comparison of the biosorption process of copper ions onto olive stone and pine bark. J Ind Eng Chem 17:824–833

Elangovan R, Philip L, Chandraraj K (2008a) Biosorption of chromium species by aquatic weeds: kinetics and mechanism studies. J Hazard Mater 152:100–112

Elangovan R, Philip L, Chandraraj K (2008b) Biosorption of hexavalent and trivalent chromium by palm flower (Borassus aethiopum). Chem Eng J 141:99–111

Hansen HK, Arancibia F, Gutiérrez C (2010) Adsorption of copper onto agriculture waste materials. J Hazard Mater 180:442–448

Ho YS (2006) Second–order kinetic model for the sorption of cadmium onto tree fern: a comparison of linear and non-linear methods. Water Res 40:119–125

Kamari A, Wan Ngah WS, Wong LW (2009) Shorea dasyphylla sawdust for humic acid sorption. Eur J Wood Prod 67:417–426

Karaoglu MH, Zor S, Ugurlu M (2010) Biosorption of Cr(III) from solutions using vineyard pruning waste. Chem Eng J 159:98–106

Lagergren S, Sven K (1898) Zur theorie der sogenannten adsorption gelöster stoffe. Vetenskapsakad Handl. 24:1–39

Larous S, Meniai AH, Lehocine MB (2005) Experimental study of the removal of copper from aqueous solutions by adsorption using sawdust. Desalination 185:483–490

Li Q, Zhai J, Zhang W, Wang M, Zhou J (2007) Kinetic studies of adsorption of Pb(II), Cr(III) and Cu(II) from aqueous solution by sawdust and modified peanut husk. J Hazard Mater 141:163–167

Lugo–Lugo V, Barrera-Díaz C, Ureña-Núñez F, Bilyeu B, Linares-Hernández I (2012) Biosorption of Cr(III) and Fe(III) in single and binary systems onto pretreated orange peel. J Environ Manage 112:120–127

Meena AK, Kadirvelu K, Mishra GK, Rajagopal C, Nagar PN (2008) Adsorptive removal of heavy metals from aqueous solution by treated sawdust (Acacia arabica). J Hazard Mater 150:604–611

Nanseu-Njiki CHP, Dedzo GK, Ngameni E (2010) Study of the removal of paraquat from aqueous solution by biosorption onto Ayous (Triplochiton schleroxylon) sawdust. J Hazard Mater 179:63–71

Ofomaja AE (2010) Intraparticle diffusion process for lead(II) biosorption onto mansonia wood sawdust. Bioresour Technol 100:5868–5876

Ofomaja AE (2011) Kinetics and pseudo–isotherm studies of 4-nitrophenol adsorption onto mansonia wood sawdust. Ind Crop Prod 33:418–428

Ofomaja AE, Ho YS (2008) Effect of temperatures and pH on methyl violet biosorption by mansonia wood sawdust. Bioresour Technol 99:5411–5417

Ofomaja AE, Unuabonah EI (2011) Adsorption kinetics of 4-nitrophenol onto a cellulosic material, mansonia wood sawdust and multistage batch adsorption process optimization. Carbohyd Polym 83:1192–1200

Ofomaja AE, Unuabonah EI, Oladoja NA (2010) Competitive modeling for the biosorptive removal of copper and lead ions from aqueous solution by mansonia wood sawdust. Bioresour Technol 101:3844–3852

Rafatullah M, Sulaiman O, Hashim R, Ahmad A (2009) Adsorption of copper(II) chromium(III) nickel(II) and lead(II) ions from aqueous solutions by meranti sawdust. J Hazard Mater 170:969–977

Rahman MS, Islam MR (2009) Effects of pH on isotherms modeling for Cu(II) ions adsorption using maple wood sawdust. Chem Eng J 149:273–280

Reddy DHK, Seshaiah K, Reddy AVR, Lee SM (2012) Optimization of Cd(II), Cu(II) and Ni(II) biosorption by chemically modified Moringa oleifera leaves powder. Carbohydr Polym 88:1077–1086

Schiewer S, Patil SB (2008) Modeling the effect of pH on biosorption of heavy metals by citrus peels. J Hazard Mater 157:8–17

Sciban M, Klasnja M (2004) Wood sawdust and wood originate materials as adsorbents for heavy metal ions. Holz Roh-Werkst 62:69–73

Sciban M, Klasnja M, Skrbic B (2006a) Modified hardwood sawdust as adsorbent of heavy metal ions from water. Wood Sci Technol 40:217–227

Sciban M, Klasnja M, Skrbic B (2006b) Modified softwood sawdust as adsorbent of heavy metal ions from water. J Hazard Mater 136:266–271

Srinivasa Rao P, Suresh Reddy KVN, Kalyani S, Krishnaiah A (2007) Comparative sorption of copper and nickel from aqueous solutions by natural neem (Azadirachta indica) sawdust and acid treated sawdust. Wood Sci Technol 41:427–442

Šváb M, Sukdolová K, Švábová M (2011) Competitive adsorption of toxic metals on activated carbon. Cent Eur J Chem 9:437–445

Wan Ngah WS, Hanafiah MAKM (2008) Adsorption of copper on rubber (Hevea brasiliensis) leaf powder: kinetic, equilibrium and thermodynamic studies. Biochem Eng J 39:521–530

Witek–Krowiak A (2011) Analysis of influence of process conditions on kinetics of malachite green biosorption onto beech sawdust. Chem Eng J 171:976–985

Witek-Krowiak A, Reddy DHK (2013) Removal of microelemental Cr(III) and Cu(II) by using soybean meal waste—Unusual isotherms and insights of binding mechanism. Bioresour Technol 127:350–357

Witek-Krowiak A, Mitek M, Pokomeda K, Szafran RG, Modelski SZ (2010) Biosorption of cationic dyes by beech sawdust II. Effect of parameters on the process efficiency. Chem Proc Eng 31:421–432

Witek–Krowiak A, Szafran RG, Modelski SZ (2011) Biosorption of heavy metals from aqueous solutions onto peanut shell as a low-cost biosorbent. Desalination 265:126–134

Acknowledgments

The work was financed by a statutory activity subsidy from the Polish Ministry of Science and Higher Education for the Faculty of Chemistry of Wroclaw University of Technology (S10033/Z0307).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Witek-Krowiak, A. Application of beech sawdust for removal of heavy metals from water: biosorption and desorption studies. Eur. J. Wood Prod. 71, 227–236 (2013). https://doi.org/10.1007/s00107-013-0673-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0673-8