Abstract

The present work demonstrated the removal of hexavalent chromium from aqueous solutions on synthesized graphene oxide (GO) from graphite. The prepared GO was characterized by various analytical techniques such as X-ray diffraction, scanning electron micrograph, Fourier transformed infrared and zero point change. The entire metal adsorption study was conducted through batch mode with keeping constant stirring rate (150 rpm). The operating variables such as pH (2–8), contact time (1–60 min), adsorbent dose (0.005 g–0.01 g L−1) and initial concentration (5–80 µg L−1) were considered, and optimized variables were fixed at maximum percentage of removal. The studied results ascertained that the maximum removal (92.8%) was achieved at acidic pH(4). The equilibrium of Cr(VI) adsorption data was nicely fitted with Langmuir model with maximum adsorption capacity (qm) 1.222 µg g−1. The sorption kinetics was nicely explained with pseudo-first-order and intraparticle diffusion mechanism. Thermodynamics of Cr(VI) adsorption revealed that the adsorption was spontaneous, endothermic and entropy-driven process. Therefore, it is concluded that graphene oxide could be an effective and efficient alternative toward removal of Cr(VI) from aqueous solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rapid growth of industrial development leads to excessive heavy metal load in the environment (Bhattacharya et al. 2019). Many industries including tannery, electroplating, metal extraction, paints and pigments, chrome industries, etc., serve as the excellent source of heavy metals. Among the different toxic metals, chromium is considered as a potent toxic metal. It exists mainly in hexavalent [Cr(VI)] and trivalent [Cr(III)] states in the aquatic body. Hexavalent chromium is almost 1000 times greater toxic than trivalent chromium (Karthik and Meenakshi 2014). However, different forms of chromium in aquatic medium mainly depend on the pH of the aquatic body. Under acidic pH, chromium exists as negative species such as Cr2O4, HCrO4−, Cr2O72−, HCr2O7−. (Khan et al. 2017). In aquatic medium, the chemistry of chromium also revealed that hexavalent chromium Cr(VI) is thermodynamically more stable than trivalent chromium Cr(III) (Dhal et al. 2013) and also Cr(VI) is dynamic and migrated easily from soil to water or vice versa (Zhang et al. 2018), whereas Cr(III) does not show such mobility.

When aquatic body is contaminated with Cr(VI), it causes many health problems such as irritation, dermatitis, vomiting, nausea. Toxicological study revealed that hexavalent chromium may cause mutagenic, carcinogenic and teratogenic effects (Duranoğlu et al. 2012; Alemayehu et al. 2011). Chromium mainly enters in the human body through food, water and even through respiratory system, and it is mainly present as trivalent state [Cr(III)] in the blood and maintains the blood metabolism (Ali et al. 2016). The tolerable limit of Cr(VI) is 50 µg L−1 in potable water; however, 100 µg L−1 is for the inland surface water (Khan et al. 2017). The recommended dose of daily dietary intake (DDI) of chromium is 50–200 µg day−1 (Ali et al. 2016). However, World Health Organization (WHO) stipulated the discharge standard of Cr(VI) into inland is 0.2 mg L−1 and drinking water must be below 0.05 mg L−1 (Duranoğlu et al. 2012) and as per USEPA, it should be 0.1 mg L−1 (Lyu et al. 2017). Therefore, it is imperative that the level of Cr(VI) from contaminated water should be reduced below permissible limit. There are numerous methods available through which Cr(VI) can be removed such as reverse osmosis, electrodialysis, precipitation, ion-exchange, ultrafiltration (Owlad et al. 2009). However, above-mentioned methods have many limitations such as generation of excessive sludge formation and high operational cost. However, the above problems can be overcome by introducing adsorption technique which is very easy to operate, sludge free environment and low cost (Samiey et al. 2014).

Previous studies (Mondal and Nayek 2019; Mondal et al. 2019a) highlighted that many such easily available biosorbents like rice bran, fly ash, spent activated clay, activated rice husk carbon, saw dust, floating macrophytes and magnolia leaf, etc., have been used for removal of Cr(VI) from aqueous medium. However, none of the adsorbent shows excellent performance toward significant Cr(VI) removal efficiency as well as adsorption capacity. Very recently, Mondal et al. (2019b, c; Mondal and Basu 2019) reported that Cr(VI) can be removed by using mosambi peel, chicken feather and human hair. Therefore, more new materials should be developed so that effective Cr(VI) removal can be achieved. Carbon atoms arranged in a systematic hexagonal layer form as when such layer arranged one by one to from graphite and force behind the binding between two layers is Van der Waals force. This special form of carbon is called graphite. It is an allotropic form of carbon. When a single hexagonal layer is separated from graphite, it is known as graphene. Graphite can be converted to graphene oxide which is the functionalized form of graphene. Recently, it is highlighted that graphene and graphene oxide can act as an excellent absorbent for removal of dye (Li et al. 2011a, b) arsenic (Chandra et al. 2010) and fluoride (Li et al. 2011a, b), heavy metals (Deng et al. 2010), from aqueous solutions. Keeping in mind the above fact, the present research is formulated in such a way that graphene oxide can be formed from graphite and the same is used for removal of Cr(VI) from laboratory made solution through batch study with varying initial concentration absorbent dose, contact time, pH and temperature.

Materials and methods

Preparation of Graphene Oxide (GO)

Modified Hummers and Offeman’s (1958) method was used for synthesis of GO. Initially, 2.0 g of graphite flakes along with 2.0 g of NaNO3 and 90 mL concentrated H2SO4 were mixed and kept in ice bath and stirring for 1 h. Then, very slowly 12.0 g KMnO4 was added an again stirring for next 3.0 h. The entire reaction chamber was kept at less than 15 °C. The mixture was then diluted by adding cold water and temperature maintained at 35 °C with continuous stirring. Then, the mixture was transfer to a reflux system at 98 °C for 10–15 min. After that the temperature was changed to 30°C which resulted in a brown colored solution. Finally, the mixture was treated with H2O2 which transformed the color to bright yellow. The brown color solution was added to a beaker containing 200 mL of water and stirred for 1 h. After stirring, the mixture was kept undisturbed for 3–4 h for complete settling. The settled material was repeatedly washed and centrifugation with 10% HCl followed by deionized water until a gel-like substance was obtained. Finally, the material was vacuum dried at 60 °C for 7 h and powders GO was stored in a dry container.

Determination of pHzpc

Zero point charge is a very important parameter for predicting the exact mechanism of adsorption by varying pH of the reaction mixture. In this study, zero point charge was determined by the solid addition method (Mondal 2010). 0.1 M KNO3 solution was taken in different conical flasks, and pH of the flask was adjusted from 1.0 to 10.0 by using 0.5 N HNO3 or 0.1 N KOH. Then, 0.5 g of GO was added to each flask which was securely capped immediately and stirred for 48 h. The pH values of the supernatant liquid were noted after 48 h.

Batch experiments

After varying all the operating variables, final solution was treated with 1–5 diphenyl carbazide and purple color was measured by UV-Spectrophotometer. The percentage of removal was calculated by following equation (Eq. 1)

where Cinitial and Cfinal are the concentrations of Cr(VI) at the initial and at the end of the adsorption process.

XRD, FTIR and SEM study

Different analytical instruments were used such as scanning electron microscope (SEM) (HITACHI-S-530), Fourier transform infrared spectroscopy (FTIR) (BRUKER, Tensor 27) and X-ray diffraction (XRD) (D500 Siemens (Germany).

Isotherms, kinetics and thermodynamic study

Equilibrium of Cr(VI) adsorption data fitted with Freundlich, Langmuir and D-R isotherms model. Equilibrium data were analyzed by fitting the data in the linear equations, and constants of different isotherm equations were evaluated. Kinetics of Cr(VI) adsorption onto GO was evaluated by applying linear form of pseudo-first-order, pseudo-second-order and intraparticle diffusions. The thermodynamics of Cr(VI) adsorption was studied through entropy, enthalpy and free energy calculation.

Results and discussion

Characterization of graphene oxide

UV–vis spectroscopy study

After synthesis of GO from graphite, the optical absorption measurements were carried out by UV–visible spectrometric signature (Fig. 1) that clearly demonstrated the formation of GO which agrees with the literature value (Choi et al. 2010). Figure 1 clearly highlighted that there is a sharp peak at 237 nm which is the results of π–π* transition of the atomic C–C bond. However, there is a small peak at 300 nm which is perhaps due to π–π* transition of aromatic carbon–carbon bond as reported by previous researcher (Xu et al. 2013).

Scanning electron microscopy (SEM)

The scanning electron micrograph (Fig. 2a) of graphene oxide indicates a very rough and heterogamous surface structure. However, originally graphene has a layer structure. On fictionalization, GO exhibits a three-dimensional network of randomly oriented sheet-like structures with a wrinkled texture and hierarchical pores with a wide size distribution which may be the preferable sites for heavy metal binding (Liu et al. 2019). After chromium removal, SEM structure of GO showed a more smooth surface (Fig. 2b) which may be due to chromium adsorption on the surface GO. Almost similar reason has been expressed by the earlier researcher (Li et al. 2013). Very recently, Janik et al. (2018) reported almost similar type of TEM structure of graphene oxide modified with amino silanes.

X-ray diffraction (XRD) study

The XRD pattern of graphite and graphene oxide is presented in Fig. 3a and b, respectively. The XRD pattern GO was dominated by single broad peak at 2θ = 25.1, which correspond to an interlayer distance of 0.84 nm. Almost similar observation was reported by the earlier researchers (Gohel et al. 2017).

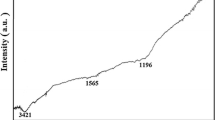

Fourier transform infrared spectroscopy (FTIR) study

The intense band at 3296 cm−1 attributed the O-H stretching vibration and the bands at 1705 cm−1 attributed C=N stretching vibration and the bands at 1043 cm−1 signify the skeletal vibrations from unoxidized graphitic domains (Fig. 4a). The band at 1037 cm−1 indicates C–O stretching vibrations. Moreover, other characteristics peaks at 1570 cm−1 correspond to the carbon–carbon double bond vibration spectrum of porphyring and the peak at 1043 cm−1 possibly due to –C–O stretching frequency. On the other hand, another sharp peak was recorded at 1705 cm−1 which is corroborated with the –C=N stretching frequency of porphyring ring. The disappearance of the peak at 463 cm−1 clearly indicates that in graphene oxide –C–O functional groups may completely be involved toward binding of chromium (Fig. 4b). Kumar et al. (2013) demonstrated almost similar findings in their research.

Zero point charge (pHzpc)

From Figure S1, it was clear that the zero point charge of GO is 2.134. This indicate that at this particular pH, the surface of GO has no net charge. However, above this pH surface of GO behaves as negative surface and below this pH surface behaves as positive surface (Nayak et al. 2017).

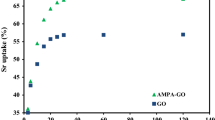

Effect of initial concentration

Adsorption experiments were conducted by varying the initial concentration 5, 10, 20, 40 and 80 mg L−1 to investigate the influence of initial concentration with keeping other conditions constant (Fig. 4). As can be revealed from Figures S2, the removal efficiency decreased with increasing initial concentrations of Cr(VI). This is probably due to quick saturation of limited available adsorbent sites at higher concentration (Dehghani et al. 2015). At lower concentration, the removal of Cr(VI) is maximum due to the ratio of the available surface area of adsorbent to the initial number of moles of Cr(VI) ions that is large (Goharshadi and Moghaddam 2015).

Effect of adsorbent dose

The influence of graphene oxide dose on removal of Cr(VI) at 30 °C is presented in Figure S3. Study results highlight that when adsorbent dose increases from 0.005 to 0.01 g, the removal of Cr(VI) increased from 31.56 to 92.8% (figure S3). However, further increase in adsorbent dose does not favor the Cr(VI) removal. Initially, removal increase with increasing adsorbent dose is probably due to availability of higher adsorption sites (Kan et al. 2017). But further increase in adsorbent dose, covered the available adsorption sites which reduced the effective adsorption (Esposito et al. 2001). Almost similar observation was reported by Dehghani et al. (2015), for removal of Cr(VI) by single- and multi-walled carbon nanotube. They explained that initial increment of Cr(VI) removal is due to the large number of vacant adsorption sites and the greater surface area hence favoring more Cr(VI) ion adsorption.

Effect of pH

pH plays a remarkable role to maintain the overall acidity or alkalinity of the aqueous solution during removal of metal ions through adsorption mechanism (Dehghani et al. 2015). The present investigation was conducted by varying the pH of the solution from pH 2 to 8 (Fig. S4). Study results indicate that at lower pH(4), maximum (92.8%) removal occurred. However, at higher pH(8), percentage of Cr(VI) removal drastically reduced to 18.38% (Fig. S4). This is quite possible, because the surface of graphene oxide is generally covered with functional groups containing oxygen-like epoxy and hydroxyl groups (Samuel et al. 2018). With the increasing pH, the availability of OH− ions concentration increases which competes with Cr(VI) ions (Zhu et al. 2011; Zhang et al. 2013). Therefore, percentage of Cr(VI) removal decreases at higher pH (Parlayici et al. 2015). On the other hand, in highly acidic medium, Cr(VI) exists as oxo-anionic form (Barrera-Díaz et al. 2012; Albadarin et al. 2012). Very recently, Samuel et al. (2019) reported that hexavalent chromium can be removed at pH 2 by using chitosan-grafted graphene oxide nanocomposite. Cr(VI) ion is mainly available in the form of HCrO4− at the pH range from 1 to 4 (Liu et al. 2019). However, purely oxo-anion, CrO42− will be available in the pH range 4–7 (Yang et al. 2014; Dehghani et al. 2015). On the other hand, the species CrO42− that is the main form of Cr(VI) will exist at pH > 7, at that time it is associated with small and tiny concentration of HCrO4− and H2CrO4, respectively (Argum et al. 2007).

Effect of contact time

The present research was conducted for removal of Cr(VI) on graphene oxide as a function of contact time (1–60 min) at a constant temperature 40 °C (Fig. S5). From the figure S5, it is clear that removal efficiency of Cr(VI) ions from aqueous solution increases rapidly up to 40 min. The higher adsorption of initial stages is perhaps due to higher availability of adsorption sites which saturates with progress of adsorption reaction (Goharshadi and Moghaddam 2015).

Effect of temperature

Temperature is one of most crucial factors which directly influence the mobility and transfer of metal ions in aqueous medium (Wang et al. 2019a, b). The effect of temperature was conducted by varying the temperature from 25 to 70 °C (Fig S6). Figure S6 shows that the percentage of Cr(VI) removal increased with increasing temperature. The higher rate of removal at higher temperature may be due to the lower kinetic energy of Cr2O72− at lower temperature. Therefore, the contact between Cr2O72− and active sites of graphene is very weak at low temperature leading to lower removal efficiency. Conversely, at higher temperature, the kinetic energy of the active species Cr2O72− overcomes the attraction potential energy between Cr2O72− and active sites available on graphene (Goharshadi and Moghaddam 2015).

Equilibrium modeling

The equilibrium data of Cr(VI) adsorption on graphene oxide were fitted on various isotherm models. In the present study, three isotherms were used such as Freundlich, Langmuir and D-R models. The linearized form of Langmuir, Freundlich and D-R isotherm equations is expressed in Eqs. 2–4:

where qm is the maximum uptake (mg g−1), qe the uptake capacity at equilibrium (mg g−1), Ce the equilibrium solution concentration (mg L−1), KL and KF are the Langmuir (L mg−1) and Freundlich (mg g−1)(L mg−1)1/n constant, respectively, and ‘n’ is the adsorption intensity.

Table 1 depicts the Cr(VI) adsorption by graphene oxide at constant temperature. The output of Langmuir constant (qm and b) and correlation coefficient (R2) is presented in Table 1. As can be seen from Table 1, the adsorption isotherm of Cr(VI) exhibited Langmuir behavior, which indicates a monolayer adsorption. The adsorption of Cr(VI) by graphene oxide is well fitted with both Freundlich and Langmuir models; therefore, the Langmuir–Freundlich equation was also applied to test the entire data sets.

Adsorption kinetics

To predict the kinetics of Cr(VI) adsorption by graphene oxide, pseudo-first-order, pseudo-second-order (HO and McKay 1999) and intraparticle diffusion kinetics models were used to check the fittings of the equilibrium data (Table 2). In Table 2, it is clearly revealed that the experimental data nicely fitted with pseudo-first-order kinetic model with R2 value 0.863. These information highlighted that the adsorption of Cr(VI) on to GO is favorable, and the same is endorsed by the pseudo-second-order equation (Hubbe et al. 2019; Aksu 2001). On the other hand, pseudo-first-order and intraparticle diffusion model are moderately fitted with the experimental data (Table 2). Almost similar observation was reported by Jiang et al. (2011).

Thermodynamics of Cr(VI) adsorption

The sorption of Cr(VI) on the GO was evaluated by the calculation of different thermodynamic parameters such as standard enthalpy (ΔH0), standard entropy (ΔS0) and standard free energy (ΔG0), and these are evaluated by following equations:

where Kc is obtained from the ratio of the concentration of Cr(VI) in the solid and liquid phases. R is the gas constant, and T is the temperature. Results revealed that initially adsorption of Cr(VI) decreases with increasing temperature which is again reflected from the variation of initial free energy change (Table 3). However, at intermediate temperature (333 K), free energy change is maximum (ΔG = − 3586.05 kJ mol−1) that means the adsorption is thermodynamically favorable at this temperature. Mondal et al. (2017) also reported such temperature dependence Cr(VI) adsorption by Aspergillus niger biomass. Very recently, Arslan et al. (2019) highlighted that magnetic particle-loaded micro-sized chitinous egg shells can remove Cr(VI) from aqueous solution.

Comparison of GO with other adsorbents for Cr(VI) adsorption

Hexavalent chromium adsorption capacity is usually determined by Langmuir and Freundlich adsorption isotherms, and it is normally reported as mg g−1. It is noted that Cr(VI) adsorbed onto other materials has been reported in the literature. Previous literature demonstrated that various materials such as modified groundnut hull (Oswalude and Tella 2016); carbon from mango kernel (Rai et al. 2016); chitosan micro-/nano-particles (Dima et al. 2015); osage orange (Pehlivan et al. 2012) have been used for removal of Cr(VI) from aqueous solution. In this study, a comparison of adsorption capacity of different adsorbents with GO is presented in Table 4. From Table 4, it is clear that very high adsorption capacity was recorded for GO, whereas adsorbents like fly ash, bentonite clay, calcined bauxite, etc., show moderate and clarified sludge, TiO2, biochar, etc., (Rajapaksha et al. 2018) exhibited low level of adsorption capacity. The present adsorbent (GO) shows low level of adsorption capacity, and it is better than fly ash and bentonite clay adsorbents.

Regeneration study

The performance of exhausted adsorbent and their subsequent use can be done through regeneration process (Wang et al. 2019a, b). The regeneration experiment was conducted by 0.1 (N) NaOH solutions. Experimental results revealed that desorption of Cr(VI) from the surface of the exhausted adsorbents is very difficult. The regeneration experimental results revealed that maximum 56.20% desorption was achieved (Figure not provided). However, the above results are one cycle regeneration with very short span of time (30 min). Almost similar regeneration status of graphene oxide/polyamidoamine dendrimers by using 0.5 M NaOH was reported by Liu et al. (2019) after one cycle. Therefore, it is strongly recommended that for achieving higher level of regeneration both duration and multi-cycling regeneration should be done. Previous research (Han et al. 2019) highlighted that GO-related adsorbent can be regenerated by using 0.5 M NaOH or HCl solution also.

Conclusion

From the present study, it can be concluded that stable graphene oxide (GO) can be prepared from graphite under laboratory condition which again proved from spectroscopic study. Study outcome also demonstrated that GO has enough potentiality toward capture of Cr(VI) from aqueous medium. Isotherm study revealed that the adsorption Cr(VI) onto GO is dominated by monolayer adsorption with adsorption capacity 1.222 mg g−1 under acidic condition (pH 4). In addition, the kinetics of Cr(VI) adsorption clearly revealed that the pseudo-second-order kinetic model accurately described the kinetic adsorption process. The kinetics of hexavalent chromium adsorption is followed pseudo-first-order kinetics and intraparticle diffusion mechanism. The thermodynamic study suggests the adsorption reaction is endothermic and entry-driven process. Therefore, conversion of graphite to graphene oxide provides a new strategy for the removal of hexavalent chromium from aqueous solutions. However, more research is needed for complete unfolding the versatility of GO and also try to enhance the adsorption capacity.

References

Aksu Z (2001) Equilibrium and kinetic modeling of Cadmium (II) biosorption by C. vulgaris in a batch system: effect of temperature. Sep Purif Technol 21:285–294

Albadarin AB, Mangwandi C, Al-MuhtasebbcGavin AH, Stephen MW, Mohammad JA, Ahmad NM (2012) Kinetic and thermodynamic of chromium ions adsorption onto low-cost dolomite adsorbent. Chem Eng J 179:193–202

Alemayehu E, Tiele-Bruhn S, Lennartz B (2011) Adsorption behaviour of Cr(VI) onto macro and micro-vesicular volcanic rocks from water. Sep Purif Technol 78:55–61

Ali A, Saeed K, Maboob F (2016) Removal of chromium(VI) from aqueous medium using chemically modified banana peels as efficient low-cost adsorbent. Alex Eng J 55:2933–2942

Arfaoui A, Frini-Srasra N, Srasra E (2008) Modelling of the adsorption of the chromium ion by modified clays. Desalination 222(1–3):474–481

Argum ME, Dursun S, Ozdemir C, Karatas M (2007) Heavy metal adsorption by modified Oak sawdust: thermodynamics and kinetics. J Hazard Mater 141:77–85

Arslan G, Sargin I, Kaya M (2019) Hexavalent chromium removal by magnetic particle-loaded micro-sized chitinous egg shells isolated from ephippia of water flea. Int J BiolMacromol. https://doi.org/10.1016/j.ijbiomac2019.01.180

Baral SS, Das SN, Rath P, Chaudhury GR (2007) Chromium(VI) removal by calcined bauxite. Biochem Eng J 34(1):69–75

Baran A, Bicak E, Baysal SH, Onal S (2006) Comparative studies on the adsorption of Cr(VI) ions on to various sorbents. Bioresour Technol 98(3):661–666

Barrera-Díaz CE et al (2012) A review of chemical, electrochemical and biological methods for aqueous Cr(VI) reduction. J Hazard Mater 223–224:1–12

Bhattacharya AK, Naiya TK, Mandal SN, Das SK (2008) Adsorption, kinetics and equilibrium studies on removal of Cr (VI) from aqueous solutions using different low-cost adsorbents. Chem Eng J 137(3):529–541

Bhattacharya A, Gupta A, Kaur A, Malik D (2019) Alleviation of hexavalent chromium by using microorganisms: insight into the strategies and complications. Water Sci Technol 79(3):411–424

Chandra V, Park J, Chun Y, Lee JW, Hwang IC, Kim KS (2010) Water-dispersible magnetite-reduced graphene oxide composites for arsenic removal. ACS Nano 4:3979–3986

Choi E-Y, Han TH, Hong J, Kim JE, Lee SH, Kim HW, Kim SO (2010) Noncovalent functionalization of graphene with end-functional polymers. J Mater Chem 10:1907–1912

Debnath S, Ghose UC (2008) Kinetics, isotherm and thermodynamics for Cr(III) and Cr(VI) adsorption from aqueous solutions by crystalline hydrous titanium oxide. J Chem Thermodyn 40(1):67–77

Dehghani MH, Mohammadtaher M, Bajpai AK, Heibati B, Tyagi I, Asif M, Agarwal S, Gupta VK (2015) Removal of Noxious Cr(VI) ions using single-walled carbon nanotubes and multi-walled carbon nanotubes. Chem Eng J 279:344–352

Deng X, Lu L, Li H, Luo F (2010) The adsorption properties of Pb(II) and Cd(II) on functionalized graphene prepared by electrolysis method. J Hazard Mater 183:923–930

Dhal B, Thatoi HN, Das NN, Pandey BD (2013) Chemical and microbial remediation of hexavalent chromium from contaminated soil and mining/metallurgical solid waste: a review. J Hazard Mater 250–251:272–291. https://doi.org/10.1016/j.jhazmat.2013.01.048

Dima JB, Seguiros C, Zaritzky NE (2015) Hexavalent chromium removal in contaminated water using reticulated chitosan micro/nanoparticles from seafood processing wastes. Chemosphere 141:100–111

Duranoğlu D, Kaya IGB, Beker U, Senkal BF (2012) Synthesis and adsorption properties of polymeric and polymer-based hybrid adsorbent for hexavalent chromium removal. Chem Eng J 181–182:103–112

Esposito A, Pagnanelli F, Lodi A, Solisio C, Vegliò F (2001) Biosorption of heavy metals by Sphaeronatans: an equilibrium study at different pH and biomass concentrations. Hydrometa 60(2):129–141

Goharshadi EK, Moghaddam MB (2015) Adsorption of hexavalent chromium ions from aqueous solution by grapheme nanosheets: kinetic and thermodynamic studies. Int Environ Sci Technol 12:2153–2160

Gohel VD, Rajput A, Gahlot S, Kulshrestha V (2017) Removal of toxic metal ions from potable water by graphene oxide composites. Macromol Symp 376:1700050. https://doi.org/10.1002/masy201700050

Guerra DL, Viana RR, Airoldi C (2009) Application of natural and modified hectorite clays as adsorbents to removal of Cr(VI) from aqueous solution—thermodynamic and equilibrium study. J Hazard Mater 172(1):507–552

Han X, Liu Y, Xiong L, Huang H, Zhang Q, Li L, Xi Yu, Wei L (2019) Facile assembly of polyaniline/graphene oxidecomposite hydrogels as adsorbent for Cr(VI) removal. Polym Compos. https://doi.org/10.1002/pc.25161

Ho YS, McKay G (1999) Batch lead(II) removal from aqueous solution by peat: equilibrium and kinetics. Process Saf Environ Prot 77:165–173

Hubbe MA, Azizian S, Douven S (2019) Implications of apparent pseudo-second-order adsorption kinetics onto cellulosic materials: a review. BioResources 14(3):75827626

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339

Janik P, Zawisza B, Talik E, Sitko R (2018) Selective adsorption and determination of hexavalent chromium ions using graphene oxide modified with amino silanes. Microchim Acta 185:117. https://doi.org/10.1007/s00604-017-2640-2

Jiang HX, Wang JS, Guo Liu Y, Li X, Ming Zeng G, Lei Bao Z, Xia Zeng X, Wei Chen A, Long F (2011) Adsorption of chromium(VI) by ethylenediamine-modified cross-linked magnetic chitosan resin: isotherms, kinetics and thermodynamics. J Hazard Mater 185:306–314

Kan C-C, Ibe AH, Rivera KKP, Aroza RO (2017) Hexavalent chromium removal from aqueous solution by adsorbents synthesized from groundwater treatment residuals. Sustain Environ Res 27:163–171

Karthik R, Meenakshi S (2014) Facile synthesis of cross linked-chitosan-grafed-polyaniline composite and its Cr(VI) uptake studies. Int J Biol Macromol 6(7):210–219

Khan SA, Riaz-ur-Rehman MA, Khan MA (1995) Adsorption of chromium(III), chromium(VI) and silver(I) on bentonite. Waste Manag 15(4):271–282

Khan TA, Nazir M, Ali I, Kuwar A (2017) Removal of chromium(VI) from aqueous solution using gum-nano zinc oxide biocomposite adsorbent. Arab J Chem 10:52388–52398

Kumar PA, Ray M, Chakraborty S (2007) Hexavalent chromium removal from wastewater using aniline formaldehyde condensate coated silica gel. J Hazard Mater 143(1–2):24–32

Kumar ASK, Kakan SS, Rajesh N (2013) A novel amine impregnated grapheme oxide adsorbent for the removal of hexavalent chromium. Chem Eng J 230:328–337

Li YH, Liu T, Du Q, Sin J, Xia Y, Wang Z, Zheng W, Wang K, Zhu H, Wu D (2011a) Adsorption of cationic red X-GRL from aqueous solutions by graphene: equilibrium kinetics and thermodynamics study. Chem Biochem Eng 25:483–491

Li YH, Zhang P, Du Q, Peng X, Liu T, Wary Z, Xia Y, Zheng W, Wang K, Zhu H, Wu D (2011b) Adsorption of fluoride from aqueous solution by grapheme. J Colloid Interface Sci 363:348–354

Li L, Fan L, Sun M, Qiu H, Li X, Duan H, Luo C (2013) Adsorbent for chromium removal based on graphene oxide functionalized with magnetic cyclodextrin–chitosan. Colloids Surf B Biointerfaces 107:76–78

Liu H, Zhang F, Peng Z (2019) Adsorption mechanism of Cr(VI) onto GO/PAMAMs composites. Sci Rep 9:3663. https://doi.org/10.1038/s41598-019-40344-9

Lyu H, Tang J, Huang Y, Gai L, Zeng EY, Liber K, Gong Y (2017) Removal of hexavalent chromium from aqueous solutions by a novel biochar supported nanoscale iron sulfide composite. Chem Eng J 322:516–524. https://doi.org/10.1016/j.cej.2017.04.058

Mi X, Huang G, Xie W, Wang W, Liu Y, Gao J (2012) Preparation of graphene oxide aerogel and its adsorption for Cu2+ ions. Carbon 50(13):4856–4864

Mondal MK (2010) Removal of Pb(II) from aqueous solution by adsorption using activated tea waste. Korean J Chem Eng 27(1):144–151

Mondal NK, Basu S (2019) Potentiality of waste human hair towards removal of chromium(VI) from solution: kinetic and equilibrium studies. Appl Water Sci 9:49. https://doi.org/10.1007/s13201-019-0929-5

Mondal NK, Nayek P (2019) Hexavalent chromium accumulation kinetics and physiological responses exhibited by Eichhornia sp. and Pistia sp. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-019-02418-z

Mondal NK, Samanta A, Dutta S, Chattaraj S (2017) Optimization of Cr(VI) biosorption onto Aspergillus niger using 3-level Box-Behnken design: equilibrium, kinetic, thermodynamic and regeneration studies. J Genet Eng Biotechnol 15(1):151–160. https://doi.org/10.1016/J.jgeb2017.01.006

Mondal NK, Samanta A, Roy P, Das B (2019a) Optimization study of adsorption parameters for removal of Cr(VI) using Magnolia leaf biomass by response surface methodology. Sustain Water Resour Manag 5(4):1627–1639

Mondal NK, Basu S, Sen K, Debnath P (2019b) Potentiality of mosambi (Citrus limetta) peel dust toward removal of Cr(VI) from aqueous solution: an optimization study. Appl Water Sci 9(4):116. https://doi.org/10.1007/s13201-019-0997-6

Mondal NK, Basu S, Das B (2019c) Decontamination and optimization study of hexavalent chromium on modified chicken feather using response surface methodology. Appl Water Sci 9:50. https://doi.org/10.1007/s13201-019-0930-z

Nayak B, Samant A, Patel R, Misra PK (2017) Comprehensive understanding of the kinetics and mechanism of fluoride removal over a potent nanocrystalline hydroxyapatite surface. ACS Omega 2:8118–8128

Oswalude SO, Tella AC (2016) Removal of hexavalent chromium from aqueous solutions by adsorption on modified groundnut hull. Beni-Sucf Univ J Basic Appl 5(4):377–388

Owlad M, Aroua MK, Wan AWD, Baroutian S (2009) Removal of hexavalent chromium-contaminated water and wastewater: a review. Water Air Soil Pollut 200:59–77. https://doi.org/10.1007/s11270-008-9893-7

Parlayici S, Eskizeybek V, Avci A, Pehlivan E (2015) Removal of Chromium(VI) using activated carbon-supported- functionalized carbon nanotubes. J Nanostuct Chem 5:255–263

Pehlivan E, Pehlivan E, Kahraman HT (2012) Hexavalent chromium removal by Osage Orange. Food Chem 133(4):1478–1484

Rai MK, Shahi G, Meena V, Meena R, Meena S, Chakraborty S, Singh RS, Rai BN (2016) Removal of hexavalent chromium Cr(VI) using activated carbon prepared from mango kernel activated with H3PO4. Resour Eff Technol 2(1):563–570

Rajapaksha AU, Alam MS, Chen H, Alessi DS, Igalanithana AD, Tsang DCW, Ok YS (2018) Removal of hexavalent chromium in aqueous solutions using biochar: chemical and spectroscopic investigations. Sci Total Environ 625(1):1567–1573

Rao M, Parwate AV, Bhole AG (2002) Removal of Cr6+ and Ni2+ from aqueous solution using bagasse and fly ash. Waste Manag 22:821–830

Samiey B, Cheng CH, Wu J (2014) Organic-inorganic hybrid polymers as adsorbents for removal of heavy metal ions from solutions: a review. Materials 7(2):673–726

Samuel MS, Shah S, Subramaniyan V, Qureshi T, Bhattacharya J, PradeepSingh ND (2018) Preparation of graphene oxide/chitosan/ferrite nanocomposite for chromium(VI) removal from aqueous solution. Int J Biol Macromol 119:540–547

Samuel MS, Bhattacharya J, Raj S, Santhanam N, Singh H, Pradeep Singh ND (2019) Efficient removal of chromium(VI) from aqueous solution using chitosan grafted graphene oxide (CS-GO) nanocomposite. Int J Biol Macromol 121:285–292. https://doi.org/10.1016/j.ijbiomac.2018.09.170

Wang H, Yuan X, Wu Y, Huang H, Zeng G, Liu Y, Wang X, Lin N, Qi Y (2013) Adsorption characteristics and behaviors of graphene oxide for Zn(II) removal from aqueous solution. Appl Surf Sci 279:432–440

Wang X, Xu J, Liu J, Liu J, Xia F, Wang C, Dahlgren RA, Liu W (2019a) Mechanism of Cr(VI) removal by magnetic greigite/biochar composites. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2019.134414

Wang Y, Zhang N, Chen D, Ma D, Liu G, Zou X, Chen Y, Shu R, Song Q, Lv W (2019b) Facile synthesis of acid-modified UiO-66 to enhance the removal of Cr(VI) from aqueous solutions. Sci Total Environ 682:118–127. https://doi.org/10.1016/j.scitotenv.2019.04.4070048-9697

Xu S, Yang L, Wu P (2013) One-pot, green, rapid synthesis of flower like gold nanoparticles/ reduced graphene oxide composite with regenerated silk fibroin as efficient oxygen reduction electrocatalysts. ACS Appl Mater Interface 5:654–662

Yang JB, Yu MQ, Qiu T (2014) Adsorption thermodynamics and kinetics of Cr(VI) on KIP210 resin. J Ind Eng Chem 20:480–486

Ying L, Qinyan Y, Baoyu G, Qian L, Chunling L (2008) Adsorption thermodynamic and kinetic studies of dissolved chromium onto humic acids. Colloids Surf B Biointerfaces 65:25–29

Zhang LH, Sun Q, Liu DH, Lu AH (2013) Magnetic hollow carbon nanospheres for removal of chromium ions. J Mater Chem A 1:9477–9483

Zhang K, Li H, Xu X, Yu H (2018) Synthesis of reduced graphene oxide/NiO nanocomposites for the removal of Cr(VI) from aqueous water by adsorption. Microporous Mesoporous Mater 255:7–14. https://doi.org/10.1016/j.micromeso.2017.07.037

Zhao G, Li J, Ren X, Chen C, Wang X (2011) Few-layered graphene oxide nanosheets as superior sorbents for heavy metal ion pollution management. Environ Sci Technol 45:10454–10462

Zhu J, Wei S, Gu H, Rapole SB, Wang Q, Luo Z, Haldolaarachchige N, Young DP, Guo Z (2011) One-pot synthesis of magnetic graphene nanocomposites decorated with core@ double-shell nanoparticles for fast chromium removal. Environ Sci Technol 46:977–985

Acknowledgements

Authors are gratefully acknowledged to the Department of Science and Technology, Government of West Bengal for financial support (WBDST Grants No. F. No. ST/P/SNT/15G-10/2015). The authors are thankful to all faculty members and nonteaching staff of the Department of Environmental Science, University of Burdwan, West Bengal, India for providing infrastructural facilities and active moral support toward completion of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mondal, N.K., Chakraborty, S. Adsorption of Cr(VI) from aqueous solution on graphene oxide (GO) prepared from graphite: equilibrium, kinetic and thermodynamic studies. Appl Water Sci 10, 61 (2020). https://doi.org/10.1007/s13201-020-1142-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-020-1142-2