Abstract

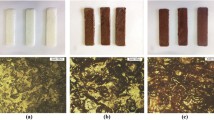

Different agro-industrial wastes were mixed with different plasticizers and extruded to form the pellets to be used further for development of biodegradable molded pots. Bulk density and macro-porosity are the important engineering properties used to determine the functional characteristics of the biodegradable pellets viz., expansion volume, water solubility, product colour, flowability and compactness. Significant differences in the functional properties of pellets with varying bulk densities (loose and tapped) and macro-porosities (loose, tapped) were observed. The observed mean bulk density of biodegradable pellets made from different formulations ranged between 0.213 and 0.560 g/ml for loose fill conditions and 0.248 to 0.604 g/ml for tapped fill conditions. Biodegradable pellets bear a good compaction for both loose and tapped fill methods. The mean macro-porosity of biodegradable pellets ranged between 1.19 and 54.48 % for loose fill condition and 0.29 to 53.35 % for tapped fill condition. Hausner ratio (HR) for biodegradable pellets varied from 1.026 to 1.328, indicating a good flowability of biodegradable pellets. Pearson’s correlation between engineering properties and functional properties of biodegradable pellets revealed that from engineering properties functional properties can be predicted.

Similar content being viewed by others

References

Ainsworth P, Ibanoglu S, Plunkett A, Ibanoglu E, Stojceska V (2007) Effect of brewers spent grain addition and screw speed on the selected physical and nutritional properties of an extruded snack. J Food Eng 81(4):702–709

Anonymous (1979) Classification of rocks and soils for engineering geological mapping. Part I: rock and soil materials. Bull Int Assoc Eng Geol 4(19):364–371

AOAC (1995) Official methods of analysis. U.S.A Assoc of Official Anal Chem, Washington

ASABE S269.4 (2002) Cubes, pellets, and crumbles-definitions and methods for determining density, durability, and moisture content. Am Soc Agric Biol Eng St. Joseph US

Avella MD, Pace E, Immirzi B, Impallomeni G, Malinconico M, Santagata G (2007) Addition of glycerol plasticizer to seaweeds derived alginates: influence of microstructure on chemical–physical properties. Carbohydr Polym 69(3):503–511

Barletta BJ, Knight KM, Barbosa-Canovas GV (1993) Compaction characteristics of agglomerated coffee during tapping. J Texture Stud 24(3):253–268

BSI (2010) EN 15210–15211:2009-solid biofuels-determination of mechanical durability of pellets and briquettes. BSI, London

Carr E (1965) Evaluating flow properties of solids. Chem Eng 72(2):163–168

Carvalho CWP, Takeiti CY, Onwulata CI, Pordesimo LO (2010) Relative effect of particle size on the physical properties of corn meal extrudates: effect of particle size on the extrusion of corn meal. J Food Eng 98(1):103–109

Chaplin MF (2003) Fiber and water binding. Proc Nutr Soc 62:223–227

Charunuch C, Limsangouan N, Prasert W, Wongkrajang K (2014) Optimization of extrusion conditions for ready-to-eat breakfast cereal enhanced with defatted rice bran. Int Food Res J 21(2):713–722

Chevanan N, Womac AR, Bitra VS (2008) Loose-Filled and Tapped Densities of Chopped Switchgrass, Corn Stover and Wheat Straw. ASABE Paper No. 084085. St. Joseph, MI

Christoph R, Schmidt B, Steinberner U, Dilla W (2000) Glycerol. Ullmann’s encyclopedia of industrial chemistry. Wiley, Weinheim, p 2

Cuq B, Gontard N, Guilbert S (1998) Proteins as agricultural polymers for packaging production. Cereal Chem 75(1):1–9

Desrumaux A, Bouvier JM, Burri J (1998) Corn grits particle size and distribution effects on the characteristics of expanded extrudates. J Food Sci 63(5):857–863

Dreese PC, Hoseney RC (1982) Baking properties of bran fractions from brewer’s spent grains. Cereal Chem 59(2):89–91

Evans MR, Hensley DL (2004) Plant growth in plastic, peat, and processed poultry feather fiber growing containers. Hortic Sci 39(5):1012–1014

Evans MR, Karcher D (2004) Properties of plastic, peat, and processed poultry feather fiber growing containers. Hortic Sci 39(5):1008–1011

Fan J, Mitchell JR, Blanchard JMV (1996) The effect of sugars on the extrusion of maize grits: I. The role of the glass transition in determining product density and shape. Int J Food Sci Technol 31(1):55–65

Gamlath S, Ravindran G (2009) Extruded products with fenugreek (trigonella foenum-graecium) chickpea and rice: physical properties, sensory acceptability and glycaemic index. J Food Eng 90(1):44–52

Garcia RA, Flores RA, Mazenko CE (2007) Factors contributing to the poor bulk behavior of meat and bone meal and methods for improving these behaviours. Bioresour Technol 98(15):2852–2858

Grey RO, Beddow JK (1969) On the Hausner ratio and its relationship to some properties of metal powders. Powder Technol 2(6):323–326

Hamel S, Krumm W (2008) Near-wall porosity characteristics of fixed beds packed with wood chips. Powder Technol 188(1):55–63

Haridas RP, Hemamalini R (1991) Effect of incorporating wheat bran on rheological characteristics and bread making quality of flour. J Food Sci Technol 28(2):92–97

Hayes GD (1987) Food engineering data handbook. Longman Scientific and Technical, New York

Igathinathane C, Jaya ST, Sokhansanj S, Bi X, Lim CJ, Melin S, Mohammad E (2010) Simple and inexpensive method of wood pellets macro-porosity measurement. Bioresour Technol 101(16):6528–6537

Keshi KJ, Huang Q (2009) Engineering Zein films with controlled surface morphology and hydrophilicity. J Agric Food Chem 57:2186–2192

Kowalska E, Wielgosz Z, Pelka J (2002) Use of post-life waste and production waste in thermoplastic polymer compositions. Polym Polym Compos 10(1):83–91

Krochta JM (2002) Proteins as raw materials for films and coatings: definitions, current status, and opportunities. Protein-based films and coatings 1–41

Malinconico M, Immirzi B, Massenti S, Mantia LFP, Mormile P, Petti (2002) L Blends of polyvinylalcohol and functionalized polycaprolactone. A study of the melt extrusion and post-cure of films suitable for protected cultivation. J Mater Sci 37(23):4973–4978

Manisha J, Srivastava T, Saxena DC (2012) Extrusion processing of deoiled rice bran in the development of biodegradable molded sheets. School J Agric Sci 2(8):163–178

Mendonca S, Grossmann MVE, Verhe R (2000) Corn bran as a fiber source in expanded snacks. LWT Food Sci Technol 33(1):2–8

Mohanty AK, Misra M, Hinrichsen (2000) Biofibres, biodegradable polymers and biocomposites: an overview. Macromol Mat Eng 276–277(1):1–24

Nalladurai K, Morey VR (2009) Factors affecting strength and durability of densified biomass products. Biomass Bioenerg 33(3):337–359

Nehru C, Alvin R, Venkata W, Bitra SP, Igathinathane C, Yuechuan T, Petre MIY, Shahab S (2010) Bulk density and compaction behavior of knife mill chopped switchgrass, wheat straw, and corn stover. Bioresour Technol 101(1):207–214

Oladeji JT (2012) A comparative study of effects of some processing parameters on densification characteristics of briquettes produced from two species of corncob. Pac J Sci Technol 13(1):182–192

Petukhov M, Cregut D, Soares CM, Serrano L (1999) Local water bridges and protein conformational stability. Protein Sci 8(10):1982–1989

Podzeck F (1998) Particle–particle adhesion in pharmaceutical powder handling. Imperial College Press, London, pp 95–114

Rabier F, Temmerman M, Bohm T, Hartmann H, Jensen PD, Rathbauer J, Carrasco J, Fernndez M (2006) Particle density determination of pellets and briquettes. Biomass Bioenergy 30(11):954–963

Schussele A, Bauer-Brandl A (2003) Note on the measurement of flowability according to the European pharmacopoeia. Int J Pharm 257(1–2):301–304

Sengar SH, Mohod AG, Khandetod YP (2012) Performance evaluation of kiln for cashew nut shell carbonization and liquid. Int J Energ Eng 2(3):78–85

Stojceska V, Ainsworth P, Plunkett A, Ibanoglu E, Ibanoglu S (2008) Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready to- eat expanded snacks. J Food Eng 87(4):554–563

Tanya MR (2006) Water structure and interactions with protein surfaces. Curr Opin Struct Biol 16(2):152–159

Wu Q, Sakabe H, Isobe S (2003) Processing and properties of low cost corn gluten meal/wood fiber composite. Ind Eng Chem Res 42(26):6765–6773

Wypych G (2012) Handbook of Plasticizers (2nd edition). William Andrew Publishing, Boston. SN 978-1-895198-50-8, 11, 307–419

Yamauchi M, Masuda S, Kihara M (2006) Recycled pots using sweet potato distillation lees. Res Conser Recycl 47(2):183–194

Yamazaki WT (1953) An alkaline water retention capacity test for the evaluation of cooking baking potentialities of soft winter wheat flours. Cereal Chem 30(3):242–246

Yanniotis S, Petraki A, Soumpasi E (2007) Effect of pectin and wheat fibers on quality attributes of extruded cornstarch. J Food Eng 80(2):594–599

Zayas JF (1997) Solubility of proteins. In Functionality of proteins in food (pp. 6–75). Springer Berlin Heidelberg

Acknowledgments

The first author is grateful to Council of Scientific and Industrial Research (CSIR), New Delhi, Govt. of India for providing financial assistance in the form of Senior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Highlights

1. As these pellets are actually extruded forms of biological materials like deoiled rice bran, paddy husk, potato peel and banana peel along with glycerol and Cashew Nut Shell Liquid (CNSL) as plasticizer, microscopic pores and channels within them cannot be avoided which makes the pellets hygroscopic in nature which not only affects the volume but also influences its mass.

2. Determining the effect of fill volume and fill method (loose and tapped) on the macro-porosity, bulk density and specific weight of biodegradable pellets helps to understand the handling, storage and packaging of these pellets.

3. Correlation of engineering and Functional properties of the biodegradable pellets made from different formulations determines the functional characteristics of the biodegradable pellets viz., expansion volume, water solubility, product colour, flowability and compactness

4. Component analysis helps in the grouping of different samples.

Rights and permissions

About this article

Cite this article

Jan, K., Riar, C.S. & Saxena, D.C. Engineering and functional properties of biodegradable pellets developed from various agro-industrial wastes using extrusion technology. J Food Sci Technol 52, 7625–7639 (2015). https://doi.org/10.1007/s13197-015-1938-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1938-5