Abstract

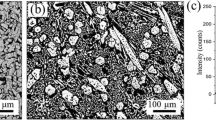

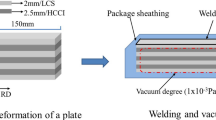

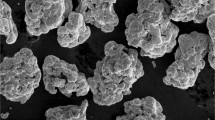

In this paper, the Hadfield steel matrix composite reinforced with dispersed high chromium cast iron (HCCI) was prepared by using the hot-rolling forming method. The microstructure and mechanical properties of the bimetal composites were analyzed. The experimental results showed that the brittle HCCI was necked and broken into uneven blocks or particles after hot-rolling deformation. The fractured hard HCCI was encased in Hadfield steel to form HCCI-reinforced Hadfield steel composite. Hot rolling results in good metallurgical bonding of the two metals, and Mn, Cr, Fe and Si elements were diffused at the interface. The wear property of the composite was higher than that of Hadfield steel. The hard HCCI played an important role in protecting the Hadfield steel matrix from wearing. The average impact toughness of the composite reached 38.2 J cm−2. The impact property of the composite was between Hadfield steel and HCCI, but significantly higher than that of as-cast iron.

Similar content being viewed by others

References

Xu L, Wang F, Lu F, Zhou Y, Chen C, and Wei S, Wear 476 (2021) 203655. https://doi.org/10.1016/j.wear.2021.203655

Jain A S, Chang H W, Tang X H, and Hinckley B, J Mater Sci 56 (2021) 1. https://doi.org/10.1007/s10853-020-05260-8

Atabaki M M, Jafari S, and Abdollah-pour H, J Iron Steel Res Int 19 (2012) 43. https://doi.org/10.1016/S1006-706X(12)60086-7

Rajicic B, Maslarevic A, Bakic G M, and Maksimovic V, Trans Indian Inst Metals 76 (2023) 1427. https://doi.org/10.1007/s12666-022-02860-7

Zhi X H, Xing J D, Fu H G, and Gao Y M, Mater Charact 59 (2008) 1221. https://doi.org/10.1016/j.matchar.2007.10.010

Cui J, Guo L, Lu H, and Li D Y, Wear 376 (2017) 587. https://doi.org/10.1016/j.wear.2016.12.031

Elghazaly W, Rashad R, Elmohr S, and Elghazaly S, Adv Mater Sci Eng 7 (2016) 1. https://doi.org/10.1155/2016/1203756

Gao X J, Jiang Z Y, Wei D B, and Kosasih B, Tribol Int 92 (2015) 117. https://doi.org/10.1016/j.triboint.2015.06.002

Chen C, et al., Tribol Int 121 (2018) 359. https://doi.org/10.1016/j.triboint.2018.01.044

Chen C, Lv B, Feng X Y, Zhang F C, and Beladi H, Mater Sci Eng A 729 (2018) 178. https://doi.org/10.1016/j.msea.2018.05.059

Zhang F C, Lv B, Wang T S, and Zheng C L, Mater Sci Technol 26 (2010) 223. https://doi.org/10.1179/174328408X363263

Niu L B, Hojamberdiev M, Xu Y H, and Hong W, J Mater Sci 45 (2010) 4532. https://doi.org/10.1007/s10853-010-4549-6

Ding Y, Cao R, and Yan Y J, Mater. Sci. Eng. A 773 (2020) 138727. https://doi.org/10.1016/j.msea.2019.138727

Huang M, Xu C, Fan G, Maawad E, Gan W, Geng L, Lin F, Tang G, Wu H, Du Y, and Li D, Acta Mater. 153 (2018) 235. https://doi.org/10.1016/j.actamat.2018.05.005

Mozaffari A, Danesh Manesh H, and Janghorban K, J Alloys Compd 489 (2010) 103. https://doi.org/10.1016/j.jallcom.2009.09.022

Azimi M, Toroghinejad M R, Shamanian M, and Kestens L A I, J Mater Sci 53 (2018) 12553. https://doi.org/10.1007/s10853-018-2510-2

Liu F, Jiang Y H, Han X, and Tan J, J Alloys Compd 618 (2015) 380. https://doi.org/10.1016/j.jallcom.2014.07.131

Li J S, Cheng G J, Yen H W, Yang Y L, Chang H Y, Wu C Y, Wang S H, and Yang J R, Mater Chem Phys 246 (2020) 122815. https://doi.org/10.1016/j.matchemphys.2020.122815

Li X, Sun Y H, Wang Z Q, and Jiang F C, J Alloys Compd 774 (2019) 656. https://doi.org/10.1016/j.jallcom.2018.10.074

Akdemir A, Kus R, and Simsir M, Mater Sci Eng A 516 (2009) 119. https://doi.org/10.1016/j.msea.2009.03.006

Avcı A, İlkaya N, Şimşir M, and Akdemir A, J Mater Process Technol 209 (2009) 1410. https://doi.org/10.1016/j.jmatprotec.2008.03.052

Huang T X, Li Z, Huang Y Q, Li Y, and Xiao P, Ceram Int 46 (2019) 2592. https://doi.org/10.1016/j.ceramint.2019.08.217

Funding

This work was funded by the Key scientific research projects of colleges and universities of Henan province (No. 24B430003), the Henan Science and Technology Plan Project (No. 232102230060) and the Doctoral Research Start-Up Fund of the Anyang Institute of Technology (No. BSJ2023003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, X., Yuan, G., Zhao, F. et al. Microstructure and Mechanical Properties of Hadfield Steel Matrix Composite Reinforced with Dispersed High Chromium Cast Iron. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-024-03332-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-024-03332-w