Abstract

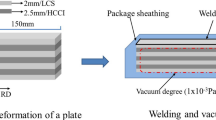

The objective of this study is to clad low-carbon steel (LCS) to high-chromium cast iron (HCCI) by using hot rolling process. The results show that the brittle HCCI can achieve plastic deformation when being cladded with LCS. The carbides of HCCI layer were broken, fractured, and refined. However, some carbide pits could be observed between the fractured carbides. The deformation mechanism of carbides was based on dislocation slip mechanism. The metallurgical bonding between HCCI and LCS was achieved under the hot-roll bonding conditions without macro-cracks and unbonded area at the interface. The atoms of Fe, Cr, Mn, and C diffused at the interface, and a decarburization zone was found near the interface on the LCS side. The highest shear strength was 312 MPa, and the failure of the shear test specimen occurred at the HCCI side when the amount of reduction increased to 40% and 50%.

Similar content being viewed by others

References

Elanchezhian C, Ramnath B V, Ramakrishnan G, Sripada K N, Mural-idharan M, Kishore V, Mater Today Proc 5 (2018) 1211.

Anderson P M, Bingert J F, Misra A, Hirth J P, Acta Mater 51 (2003) 6059.

Tang X H, Chung R, Li D Y, Hinckley B, Dolman K, Wear 267 (2009) 116.

Wu X J, Xing J D, Fu H G, Zhi X H, Mater Sci Eng A 457 (2007) 180.

Carpenter S D, Carpeter D, Pearce J, Mater Chem Phys 85 (2004) 32.

Wang Y, Gou J F, Chu R Q, Zhen D X, Liu S Y, Tribol Int 85 (2004) 32.

Liu F, Jiang Y H, Xiao H, Tan, J Alloy Comp 618 (2015) 380.

Fernández I, Belzunce F J, Mater Charact 59 (2008) 669.

Bedolla Jacuinde A, Rainforth W M, Wear 250 (2001) 449.

Gahr K, Doane D, Metall Trans A 11 (1980) 613.

Sare I R, Mater. Sci Tech-Lond 19 (2013) 412.

Li Y C, Li P, Wang K, Li H Z, Gong M Y, Tong W P, Vacuum 156 (2018) 59.

Ding H S, Liu S Q, Zhang H L, Guo J J, Mater Des 90 (2016) 958.

Jiang J P, Li S B, Hu S J, Zhou Y, Mater Chem Phys 214 (2018) 80.

Efremenko V, Shimizu K, Chabak Y, Metall Mater Trans A 44 (2013) 5435.

Chung R J, Tang X, Li D Y, Hinckley B, Dolman K, Wear 267 (2009) 356.

Ma S Q, Xing J D, He Y L, Li Y F, Huang Z F, Liu G Z, Geng Q J, Mater Chem Phys 161 (2015) 65.

Oh H S, Lee S H, Jung J Y, Ahn S H, Metall Matr Trans A 32 (2001) 515.

Kim C K, Lee S H, Jung J Y, Metall Matr Trans A 37 (2006) 633.

Sallam H, Abd EI-Aziz K, Abd EI-Raouf H, Elabanna E, Mater Des 52 (2013) 974.

Xiao X F, Ye S P, Yin W X, Xue Q, J Iron Steel Res Int 19 (2012) 13.

Xiong B W, Cai C C, Wan H, Lu B P, Mater Des 32 (2011) 2978.

Xiong B W, Cai C C, Wan H, Lu B P, J Alloy Compd 509 (2011) 6700.

Eroglu M, Kurt B, Mater Sci Tech-Lond 23 (2007) 171.

Gao X J, Jiang Z Y, Wei D B, Jiao S H, Kosasih B, Tribol Int 92 (2015) 117.

Gao X J, Jiang Z Y, Wei D B, Jiao S H, Chen D F, Xu J Z, Zhang X M, Gong D Y, Mater Des 63 (2014) 650.

Xie G L, Sheng H, Han J T, Liu J, Mater Des 31 (2010) 3062.

Xie G L, Han J T, Liu L, Jiang Z Y, Mater Sci Eng A 527 (2010) 6251.

Liu F, Jiang Y, Lu D, Xiao H, Tan J, Mater Sci Tech-lond 31 (2015) 295.

Masahashi N, Watanabe S, Hanada S, Komatsu K, Kimura G, Metall Mater Trans A 37 (2006) 1665.

Xu J Z, Gao X J, Jiang Z Y, Wei D P, Steel Res Int 87 (2016) 780.

Jiang Z Y, Gao X J, Li S L, Zhang H M, Chen D F, Xu J Z, J Iron Steel Res Int 22 (2015) 438.

Pei Y, Song R B, Zhang Y C, Huang L, Cai C H, Wen W, Zhao Z Y, Yu P, Quan S Y, Su S R, Chen C, Mater Sci Eng A 779 (2020) 139150.

Zareie Rajani H, Mousavi S, Mater Sci Eng A 556 (2012) 454.

Liu B X, An Q, Yin F X, Wang S, Chen C X, J Mater Sci 54 (2019) 11357.

Li Y C, Gong M Y, Wang K, Li P, Yang X, Tong W P, Mater Sci Eng A 718(2018) 260.

Acknowledgements

This work was supported by the National Key Research and Development Program of China [Grant number 2018YFA0707304].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, G., Zhu, X., Han, P. et al. Microstructure and Mechanical Properties of High-Chromium Cast Iron/Low-Carbon Steel Composite Prepared by Hot Rolling Process. Trans Indian Inst Met 74, 2761–2769 (2021). https://doi.org/10.1007/s12666-021-02350-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02350-2