Abstract

Nowadays, the need to use multilayered materials in various industries due to their unique properties, such as resistance to wear, corrosion, and weight lightening, is augmenting. In this paper, the production of bimetallic aluminum (AA 1050)/commercially pure Cu tubes by cold parallel tube-shaped channel angular pressing (PTCAP) process was considered for the first time. The PTCAP process was performed in three passes, and the bonding properties, microstructure, and microhardness were evaluated in each pass. The microstructure and mechanical properties of PTCAPed samples were examined by optical microscopy (OM), scanning electron microscope (SEM), energy-dispersive X-ray spectroscopy (EDS), Vickers microhardness test, and shear punch test. According to the results, the Cu and Al PTCAPed tubes’ microhardness was improved by 125 and 87%, respectively. Besides, after three passes, the mean size of grains of the copper tube decreased from 58 to 6 μm. Therefore, based on the Hall–Petch relationship, the main reason for the increase in microhardness can be stated as the significant reduction in grain size. According to the shear punch test results, after three passes of PTCAP, the shear strength between the two layers was increased by 208%. Finally, both tubes were well bonded as a bilayer tubes at higher passes.

Similar content being viewed by others

References

Findik F, Recent developments in explosive welding. Mater. Des. 32 (3), (2011) 1081–1093.

W. Schulz, J. Worringer, and D. Osborn, “Process for the manufacture of cladded metal pipes.” Google Patents, 24-Aug-1999.

Park H J, Na K H, Cho N S, Lee Y S, and Kim S-W, A study of the hydrostatic extrusion of copper-clad aluminium tube. J. Mater. Process. Technol. 67 (1–3), (1997) 24–28.

Lu L, Yuan D, Tang Y, and Cheng J, Slave rotation analysis of miniature inner grooved copper tube through rotary swaging process. Int. J. Adv. Manuf. Technol. 61 (1), (2012) 185–193.

Zhang Q, Jin K, and Mu D, Tube/tube joining technology by using rotary swaging forming method. J. Mater. Process. Technol. 214 (10), (2014) 2085–2094.

Kocich R, Macháčková A, Kunčická L, and Fojtík F, Fabrication and characterization of cold-swaged multilayered Al–Cu clad composites. Mater. Des. 71 (2015) 36–47.

Zhang Q, Zhang Y, Cao M, Ben N, Ma X, and Ma H, Joining process for copper and aluminum tubes by rotary swaging method. Int. J. Adv. Manuf. Technol. 89 (1), (2017) 163–173.

Mohebbi M S, and Akbarzadeh A, Fabrication of copper/aluminum composite tubes by spin-bonding process: experiments and modeling. Int. J. Adv. Manuf. Technol. 54 (9), (2011) 1043–1055.

Guo X, Wang H, Liu Z, Wang L, Ma F, and Tao J, Interface and performance of CLAM steel/aluminum clad tube prepared by explosive bonding method. Int. J. Adv. Manuf. Technol. 82 (1), (2016) 543–548.

Chitkara N R, and Aleem A, Extrusion of axi-symmetric bi-metallic tubes: some experiments using hollow billets and the application of a generalised slab method of analysis. Int. J. Mech. Sci. 43 (12), (2001) 2857–2882.

Chen Z, Ikeda K, Murakami T, Takeda T, and Xie J-X, Fabrication of composite pipes by multi-billet extrusion technique. J. Mater. Process. Technol. 137 (1–3), (2003) 10–16.

Krishna B V, Venugopal P, and Rao K P, Co-extrusion of dissimilar sintered P/M preforms—An explored route to produce bimetallic tubes. Mater. Sci. Eng. A 407 (1–2), (2005) 77–83.

Ghadimi S, Sedighi M, Djavanroodi F, and Asgari A, Experimental and numerical investigation of a Cu–Al bimetallic tube produced by ECAP. Mater. Manuf. Process. 30 (10), (2015) 1256–1261.

Wang X, Li P, and Wang R, Study on hydro-forming technology of manufacturing bimetallic CRA-lined pipe. Int. J. Mach. Tools Manuf. 45 (4–5), (2005) 373–378.

Sun X-J, Jie T A O, and Guo X-Z, Bonding properties of interface in Fe/Al clad tube prepared by explosive welding. Trans. Nonferrous Met. Soc. China 21 (10), (2011) 2175–2180.

Guo X, Tao J, Wang W, Li H, and Wang C, Effects of the inner mould material on the aluminium–316L stainless steel explosive clad pipe. Mater. Des. 49 (2013) 116–122.

Mohebbi M S, and Akbarzadeh A, Accumulative spin-bonding (ASB) as a novel SPD process for fabrication of nanostructured tubes. Mater. Sci. Eng. A 528 (1), (2010) 180–188.

L. S. Tóth, M. Arzaghi, J. J. Fundenberger, B. Beausir, O. Bouaziz, R. Arruffat-Massion, Severe plastic deformation of metals by high-pressure tube twisting. Scr. Mater. 60 (3), (2009) 175–177.

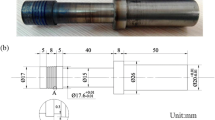

Faraji G, Mosavi M, and Seop H, Tubular channel angular pressing ( TCAP ) as a novel severe plastic deformation method for cylindrical tubes. Mater. Lett. 65 (19–20), (2011) 3009–3012.

Faraji G, Babaei A, Mashhadi M M, and Abrinia K, Parallel tubular channel angular pressing ( PTCAP ) as a new severe plastic deformation method for cylindrical tubes. Mater. Lett. 77 (2012) 82–85.

Faraji G, Mashhadi M M, Bushroa A R, and Babaei A, TEM analysis and determination of dislocation densities in nanostructured copper tube produced via parallel tubular channel angular pressing process. Mater. Sci. Eng. A 563 (2013) 193–198.

Kasaeian-naeini M, Hashemi R, and Hosseini A, Lubrication performance of rapeseed oil-based nano-lubricants in parallel tubular channel angular pressing process. J. Cent. South Univ. 26 (2019) 1042–1049.

H.-S. A. P. M. Alloys, “Properties and selection: Nonferrous alloys and special-purpose materials,” 1990.

Salehi J, Rezaeian A, and Toroghinejad M R, Fabrication and characterization of a bimetallic Al/Cu tube using the tube sinking process. Int. J. Adv. Manuf. Technol. 96 (1), (2018) 153–159.

Fronczek D M, et al., Microstructural and phase composition differences across the interfaces in Al/Ti/Al explosively welded clads. Metall. Mater. Trans. A 48 (9), (2017) 4154–4165.

Zhang T T, et al., Investigation of interface bonding mechanism of an explosively welded tri-metal titanium/aluminum/magnesium plate by nanoindentation. Jom 70 (4), (2018) 504–509.

A. Tajyar and A. Masoumi, “Experimental analysis of bonding strength in shape rolling of Al-Cu bimetallic circular pipes into square tubes,” Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci., vol. 231, no. 22, pp. 4087–4098, 2017.

Tajyar A, and Masoumi A, Investigation of mechanical properties of bimetallic square tubes produced by shape rolling of Al/Cu circular pipes. J. Mech. Sci. Technol. 30 (9), (2016) 4299–4306.

Kim I K, and Hong S I, Mechanochemical joining in cold roll-cladding of tri-layered Cu/Al/Cu composite and the interface cracking behavior. Mater. Des. 57 (2014) 625–631.

V. Yousefi Mehr, M. R. Toroghinejad, and A. Rezaeian, “The effects of oxide film and annealing treatment on the bond strength of Al-Cu strips in cold roll bonding process,” Mater. Des., vol. 53, pp. 174–181, 2014.

Eivani A R, Shojaei A, Salehi M T, Jafarian H R, and Park N, On the evolution of microstructure and fracture behavior of multilayered copper sheet fabricated by accumulative roll bonding. J. Mater. Res. Technol. 10 (2021) 291–305.

P. Eslami, A. Karimi Taheri, and M. Zebardast, “A comparison between cold-welded and diffusion-bonded Al/Cu bimetallic rods produced by ECAE process,” J. Mater. Eng. Perform., vol. 22, no. 10, pp. 3014–3023, 2013.

Lapovok R, Ng H P, Tomus D, and Estrin Y, Bimetallic copper-aluminium tube by severe plastic deformation. Scr. Mater. 66 (12), (2012) 1081–1084.

Li X, Zu G, Ding M, Mu Y, and Wang P, Interfacial microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding and annealing. Mater. Sci. Eng. A 529 (1), (2011) 485–491.

Chen C Y, Chen H L, and Hwang W S, Influence of interfacial structure development on the fracture mechanism and bond strength of aluminum/copper bimetal plate. Mater. Trans. 47 (4), (2006) 1232–1239.

Eivani A R, Shojaei A, Park N, and Jafarian H R, Fabrication of Cu-CuG nanocomposites with enhanced mechanical strength and reduced electrical resistivity. J. Mater. Res. Technol. 11 (2021) 650–666.

Shirzad S, Hashemi R, and Rajabi M, Finite Element Simulation of the Parallel Tubular Channel Angular Pressing Process for Al–Cu Bimetallic Tube with Experimental Verification. Trans. Indian Inst. Met. 75 (1), (2022) 91–100.

G. H. Faraji and M. M. MOUSAVI, “Plastic deformation analysis in parallel tubular channel angular pressing (PTCAP),” J. Adv. Mater. Process. (JOURNAL Mater. Sci., vol. 1, no. 4, pp. 23–32, 2013.

V. Tavakoli, M. Afrasiab, G. Faraji, and M.M. Mashhadi, Severe mechanical anisotropy of high strength ultrafine grained Cu-Zn tubes processed by parallel tubular channel angular pressing (PTCAP). Mater. Sci. Eng: A 625, (2015) 50–55.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alaie, M.A., Kasaeian-Naeini, M., Hashemi, R. et al. Fabrication of AA1050/CP-Cu Bimetallic Tubes using Parallel Tube-Shaped Channel Angular Pressing Technique and Assessing its Mechanical Properties and Microstructure. Trans Indian Inst Met 76, 1937–1948 (2023). https://doi.org/10.1007/s12666-023-02897-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02897-2