Abstract

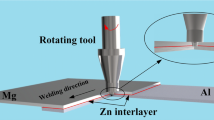

In this work, a novel friction-based welding technology was developed to weld Al/Cu bimetallic tubes. The macrostructure, microstructure evolutions, and mechanical properties of the joint under different welding speeds were investigated. Void defects are observed on the joint interface, especially at the welding speed 60 mm/min. From the Al side to the Cu side, the reaction layer can be divided into five layers. In addition, welding speed has an important influence on the microstructure evolution of reaction layer. Compression-shear testing results show that the shear strength decreases with the increase of the welding speed. The failure of compression-shear samples is first generated at the junction of hypereutectic layer and intermetallic compound (IMC) layer, and then, the crack propagates along the interface of the hypereutectic layer and IMC layer or through the hypereutectic layer to the eutectic layer.

Similar content being viewed by others

References

Tavassolimanesh A, Nia AA (2017) A new approach for manufacturing copper-clad aluminum bimetallic tubes by friction stir welding (FSW). J Manuf Process 30:374–384

Li WY, Wen Q, Yang XW, Wang YS, Gao DL, Wang WB (2017) Interface microstructure evolution and mechanical properties of Al/cu bimetallic tubes fabricated by a novel friction-based welding technology. Mater Des 134:383–393

Ma ZL, Zhang JL, Li DF (2003) Some problems of copper using in air conditioning and refrigeration system. Refrig Air Cond 3:66–70

Jin TX, Li GL, Cao YL, Xu R, Shao SQ, Yang BB (2015) Experimental research on applying the copper-clad aluminum tube as connecting tubes of air conditioners. Energy Build 97:1–5

Khojastehnezhad VM, Pourasl HH (2018) Microstructural characterization and mechanical properties of aluminum 6061-T6 plates welded with copper insert plate (Al/cu/Al) using friction stir welding. Trans Nonferrous Met Soc China 28:415–426

Tan CW, Jiang ZG, Li LQ, Chen YB, Chen XY (2013) Microstructural evolution and mechanical properties of dissimilar Al−cu joints produced by friction stir welding. Mater Design 51:466–473

Liu P, Shi Q, Wang W, Wang X, Zhang Z (2008) Microstructure and XRD analysis of FSW joints for copper T2/aluminium 5A06 dissimilar materials. Mater Lett 62:4106–4108

Shinde G, Gajghate S, Dabeer PS, Seemikeri CY (2017) Low cost friction stir welding: a review. Mater Today: Proceedings 4:8901–8910

Leitao C, Arruti E, Aldanondo E, Rodrigues DM (2016) Aluminium-steel lap joining by multipass friction stir welding. Mater Des 106:153–160

Sidhar H, Martinez NY, Mishra RS, Silvanus J (2016) Friction stir welding of Al-mg-li 1424 alloy. Mater Des 106:146–152

Carlone P, Astarita A, Palazzo GS, Paradiso V, Squillace A (2015) Microstructural aspects in al-cu dissimilar joining by FSW. Int J Adv Manuf Technol 79:1109–1116

Liu XC, Sun YF, Fujii H (2017) Clarification of microstructure evolution of aluminum during friction stir welding using liquid CO2 rapid cooling. Mater Des 129:151–163

Packer SM, Matsunaga M (2006) Friction stir welding equipment and method for joining X65 pipe. In: Proceedings of the 14th International Off shore and Polar Engineering Conference, 55–60

Maggiolini E, Tovo R, Susmel L, James MN, Hattingh DG (2016) Crack path and fracture analysis in FSW of small diameter 6082-T6 aluminium tubes under tension–torsion loading. Int J Fatigue 92:478–487

Doos QM, Wahab BA (2012) Experimental study of friction stir welding of 6061-T6 aluminum pipe. Int J Mech Eng Rob Res 1:143–156

Lammlein DH, Gibson BT, DeLapp DR, Cox C, Strauss AM, Cook GE (2012) The friction stir welding of small-diameter pipe: an experimental and numerical proof of concept for automation and manufacturing. Proc Inst Mech Eng B J Eng Manuf 226:383–398

Hattingh DG, von Welligh LG, Bernard D, Susmel L, Tovo R, James MN (2016) Semiau-tomatic friction stir welding of 38 mm OD 6082-T6 aluminium tubes. J Mater Process Technol 238:255–266

Kuang BB, Shen YF, Chen WH, Yao X, Xu HS, Gao JC, Zhang JQ (2015) The dissimilar friction stir lap welding of 1A99 al to pure cu using Zn as filler metal with “pinless” tool configuration. Mater Des 68:54–62

Zhang JQ, Shen YF, Yao X, Xu HS, Li B (2014) Investigation on dissimilar underwater friction stir lap welding of 6061-T6 aluminum alloy to pure copper. Mater Des 64:74–80

Lammlein DH, Gibson BT, DeLapp DR, Cox C, Strauss AM, Cook GE (2011) Friction stir welding of small diameter pipe: an experimental and numerical proof of concept for automation and manufacturing. Proc Inst Mech Eng B J Eng Manuf 226:383–398

Chen BX, Chen K, Hao W, Liang ZY, Yao JS, Zhang LT, Shan AI (2015) Friction stir welding of small-dimension Al3003 and pure cu pipes. J Mater Process Technol 223:48–57

Farha FA (2012) A preliminary study on the feasibility of friction stir back extrusion. Scr Mater 66:615–618

Liu T, Wang Q, Sui Y, Wang Q, Ding W (2016) An investigation into Interface formation and mechanical properties of aluminum-copper bimetal by squeeze casting. Mater Des 89:1137–1146

Funding

This study was financially supported by the National Natural Science Foundation of China (No. 51875470). The project was supported by the Fundamental Research Funds for the Central Universities (No. 3102017ZY005), the Natural Science Foundation of Shaanxi Province (No. 2018JM5159), and the National Key Research and Development Program of China (2016YFB1100104).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process Provided Funding information has to be tagged.

Rights and permissions

About this article

Cite this article

Yang, X., Li, W., Xu, Y. et al. Effect of welding speed on microstructures and mechanical properties of Al/Cu bimetal composite tubes by a novel friction-based welding process. Weld World 63, 127–136 (2019). https://doi.org/10.1007/s40194-018-0652-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0652-0