Abstract

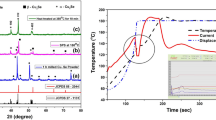

This article reports the evolution of Cu2Se thermoelectric compound during high-energy ball milling and spark plasma sintering process. The elemental copper (Cu) and selenium (Se) powders with appropriate stoichiometric ratios (Cu 66.66 at.% and Se 33.34 at.%) were milled in the high-energy ball mill at different milling times. The XRD studies of the ball-milled powders show the phase evolution with increasing milling time. The XRD analysis of 1, 5, 10 and 20 h mechanically milled powders is identified as Cu + Se, CuSe + Cu + Se, Cu3Se2 + Cu and β-Cu2Se phases, respectively. Diffusion-controlled reaction mechanism is proposed for the formation of β-Cu2Se phase after multiple intermediate phases. DTA studies also report the phase formation of α-Cu2Se from the elemental powder and intermediate phases. Spark plasma-sintered sample has shown the formation of α-Cu2Se compound irrespective of the milling time and initial phase.

Similar content being viewed by others

References

Yang C -T, Hsiang H -I, and Tu J -H, Adv Powder Technol 27 (2016) 959.

Rau H, and Rabenau A, J Solid State Chem 1 (1970) 515.

Koren B, Friedman O, Maman N, Hayun S, Ezersky V, and Golan Y, RSC Adv 12 (2022) 277.

Gulay L, Daszkiewicz M, Strok O, and Pietraszko A, Chem Met Alloy (2011) 200.

Li M, Cortie D L, Liu J, Yu D, Islam S M K N, Zhao L, Mitchell D R G, Mole R A, Cortie M B, Dou S, and Wang X, Nano Energy 53 (2018) 993.

Ducka A, Trawiński B, Bochentyn B, Dubiel A, and Kusz B, Mater Res Bull 133 (2021) 111042.

Singh V V, and Singh A K, Dalt Trans 44 (2015) 725.

Zhao K, Guan M, Qiu P, Blichfeld A B, Eikeland E, Zhu C, Ren D, Xu F, Iversen B B, Shi X, and Chen L, J Mater Chem A 6 (2018) 6977.

Shi D, Geng Z, Shi L, Li Y, and Lam K, J Mater Chem C 8 (2020) 10221.

Li M, Islam S M K N, Yahyaoglu M, Pan D, Shi X, Chen L, Aydemir U, and Wang X, InfoMat 1 (2019) 108.

Yu J, Zhao K, Qiu P, Shi X, and Chen L, Ceram Int 43 (2017) 11142.

Hu Q, Zhang Y, Zhang Y, Li X- J, and Song H, J Alloys Compd 813 (2020) 152204

Hu Q, Zhu Z, Zhang Y, Li X- J, Song H, and Zhang Y, J Mater Chem A 6 (2018) 23417

Liu K, Liu H, Wang J, and Shi L, J Alloys Compd 484 (2009) 674.

Liao W -W, Yang L, Chen J, Zhou D -L, Qu X, Zheng K, Han G, Zhou J -B, Hong M, and Chen Z -G, Chem Eng J 371 (2019) 593.

Yang L, Chen Z -G, Han G, Hong M, Zou Y, and Zou J, Nano Energy 16 (2015) 367.

Liu W, Shen L, Shai X, Sun L, Lu J, Chen J, Ge W, and Deng S, CrystEngComm 21 (2019) 6850.

Liu W, Shen L, Shai X, Tang Y, Chen Z, Sun L, Ge W, and Deng S, J Alloys Compd 791 (2019) 60.

Su X, Fu F, Yan Y, Zheng G, Liang T, Zhang Q, Cheng X, Yang D, Chi H, Tang X, and Uher C, Nat Commun 5 (2014) 1.

Zhao K, Duan H, Raghavendra N, Qiu P, Zeng Y, Zhang W, Yang J, Shi X, and Chen L, Adv Mater 29 (2017) 1701148.

Zhao L, Wang X, Fei F Y, Wang J, Cheng Z, Dou S, Wang J, and Snyder G J, J Mater Chem A 3 (2015) 9432.

Ji Y -H, Ge Z -H, Li Z, and Feng J, J Alloys Compd 680 (2016) 273.

Ohtani T, Motoki M, Koh K, and Ohshima K, Mater Res Bull 30 (1995) 1495.

Schilz J, Riffel M, Pixius K, and Meyer H -J, Powder Technol 105 (1999) 149.

Li J, Liu G, Wu X, He G, Yang Z, and Li J, Ceram Int 44 (2018) 22172.

Glazov V M, Pashinkin A S, and Fedorov V A, Inorg Mater 36 (2000) 641.

Murugasami R, Vivekanandhan P, Kumaran S, Kumar R S, and Tharakan T J, Adv Powder Technol 28 (2017) 506.

Cullity B D, Elements of X-ray Diffraction, Addison-Wesley Publishing (1956).

Yang L, Chen Z -G, Han G, Hong M, and Zou J, Acta Mater 113 (2016) 140

Taghvaei A H, Ghajari F, Markó D, and Prashanth K D, J Magn Magn Mater 395 (2015) 354.

Varol T, and Canakci A, Powder Technol 246 (2013) 462.

Vivekanandhan P, Murugasami R, Kalahasti V R S S, and Kumaran S, Powder Technol 319 (2017) 129.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

N, T., S, K. Phase Evolution Mechanism of Cu2Se Compound During Mechanical Milling and Spark Plasma Sintering Process. Trans Indian Inst Met 76, 937–944 (2023). https://doi.org/10.1007/s12666-022-02773-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02773-5