Abstract

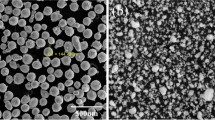

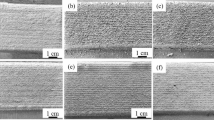

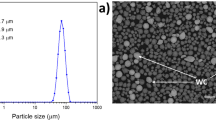

WC-reinforced Stellite-21 coatings were prepared on AISI H13 steel by laser cladding (LC). The microstructure, phases and hardness of obtained coatings were analyzed by super-depth of field microscope (SDFM), X-ray diffraction (XRD) and microhardness tester, respectively. The effects of WC mass fraction on the coefficients of friction (COF) and wear rate of WC-reinforced Stellite-21 coatings at 550 °C were investigated. The results indicated that the undissolved WC particles act as the skeleton for the Stellite-21 coating, which has a positive effect on the improvement of hardness. The average COFs of Stellite-21-10%WC, Stellite-21-20%WC and Stellite-21-30%WC coatings are 0.447, 0.383 and 0.349, respectively, and the corresponding wear rates are 192.4, 148.6 and 101.4 μm3 N−1 mm−1, respectively, showing that the wear resistance increases with the increase in the WC mass fraction, and the wear mechanism is combined by the adhesive wear, abrasive wear and slight oxidative wear.

Similar content being viewed by others

References

Fernandesa FAP, Heckb SC, Piconec CA, Casteletti LC. Surface and Coatings Technology, 2020, 381: 125216

Kashani H, Amadeh A, Ghasemi H M. Wear, 2007, 262: 800-806

Kumar S, Maity SR, Patnaik L. Ceramics International, 2020, 46: 17280-17294

Mellouli D ,Haddar N ,Koster A ,Ayedi H F. Engineering Failure Analysis, 2014, 45: 85-95

Anders P, Sture H, Jens B. Surface and Coatings Technology, 2005, 191: 216-227

Xue S,Yang T, Guo RD, Deng AL, Liu XD, Zheng LX. Engineering Failure Analysis, 2021, 120: 105083

Klobčara D, Tušeka J, Taljat B. Materials Science and Engineering A, 2008, 472:198-207

Wang B, Zhao XF, Li WZ, Qin M, Gu JF. Applied Surface Science, 2018, 431: 39-43

Beake BD, Ning L, Gey C, Veldhuis SC, Komarov A, Weaver A, Khanna M, Fox-Rabinovich GS. Surface and Coatings Technology, 2015, 279: 118-125

Yang HP, Wu XC, Cao GH, Yang Z. Surface and Coatings Technology, 2016, 307: 506-516

Chhabra P, Kaur M, Singh S. Materials Today: Proceedings,2020,33: 1518-1530

Liu B, Wang B, Yang XD, Zhao XF, Qin M, Gu JF. Applied Surface Science, 2019, 483: 45-51

Zhang WC, Liu LB, Zhang MT, Huang GX, Liang JS, Li X, Zhang LG. Transactions of Nonferrous Metals Society of China,2015,25: 3700-3707

Hao JB, Hu FT, Le XW, Liu H, Yang HF, Han, J. Journal of Materials Processing Technology,2020,291: 117036

Wu S, Liu ZH, Huang XF, Wu YF, Gong Y. International Journal of Refractory Metals and Hard Materials, 2021, 101: 105675

Lu HF, Cai J, Luo KY, Xing F, Zhang QL, Yao JH, Lu JZ. Surface and Coatings Technology,2021,408: 126808

Bartkowski D, Kinal G. International Journal of Refractory Metals and Hard Materials, 2016, 58: 157-164

Hassani FZ, Ketabchi M, Bruschi S, Ghiotti A. Journal of Materials Science, 2016, 51: 4495-4508

Ganesh P, Moitra A, Tiwari P, Sathyanarayanan S, Kumar H, Rai SK, Kaul R, Paul CP, Prasad RC, Kukreja LM. Materials Science and Engineering: A,2010,527: 3748-3756

Karmakar DP, Muvvala G, KumarNath A. Surface and Coatings Technology, 2020, 384:125331

Roy S, Sridharan N, Cakmak E, Ghaednia H, Gangopadhyay A, Qu J. Wear, 2021, 482: 203990

Lin YH, Lei YP, Li XQ, Zhi XH, Fu HG. Optics and letter in Engineering, 2016, 82: 48-55

Zeng XB, Wang QT, Chen CR, Lian GF, Huang X. Surface and Coatings Technology, 2021, 42: 127781

Erturk, AT, Sahin, M, Aras, M. Transactions of the Indian Institute of Metals, 2017, 70: 1233-1240

Bartkowski D, Bartkowska A. International Journal of Refractory Metals and Hard Materials, 2017, 64: 20-26

Karmakar DP, Muvvala G, Nath AK. Surface and Coatings Technology, 2021, 422: 127498

Kong WC, Li KM, Hu J. Optics & Laser Technology, 2021,142:107214

Xiao Q, Sun WL, Yang KX, Xing XF, Chen ZH, Zhou HN, Lu J. Surface and Coatings Technology, 2021,420: 127341

Xu PH, Zhu LD, Xue PS, Yang ZC, Wang SH, Ning JS, Meng GR, Lan Q, Qin SQ. Ceramics International,2022,48: 9218-9228

Fernández MR, García A, Cuetos JM, González R, Noriega A, Cadenas M. Wear, 2015, 324: 80-89

Van Acker K, Vanhoyweghen D, Persoons R, Vangrunderbeek J. Wear, 2005, 258: 194-202

Li WY, Yang XF, Xiao JP, Hou QM. Ceramics International,2021,47: 28754-28763

Farahmand P, Kovacevic R. Surface and Coatings Technology, 2015, 276: 121-135

Zhang KD, Deng JX, Meng R, Lei ST, Yu XM. International Journal of Refractory Metals and Hard Materials, 2016, 57: 101-114

Jeyaprakash N, Yang CH. Transactions of the Indian Institute of Metals, 2020,73:1527-1533

Hu YJ, Wang ZX, Pang M. Materials Today Communications, 2022,31:103357

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Peng, L., Dejun, K. Effect of WC Mass Fraction on Friction-Wear Performance of Laser-Cladded Stellite-21-WC Coatings at High Temperature. Trans Indian Inst Met 75, 3095–3104 (2022). https://doi.org/10.1007/s12666-022-02694-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02694-3