Abstract

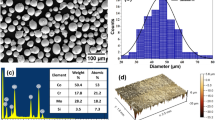

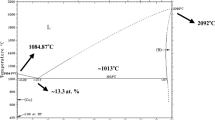

To improve the microhardness and wear resistance of Q235 steel, Stellite6/WC composite coatings were prepared on the surface of Q235 steel by laser cladding mixed powder (Stellite6, WC, W, and C powder) on its surface. The microstructure and mechanical properties of directly added WC and in situ synthesized WC were analyzed and compared by scanning electron microscope(SEM), X-ray diffractometer(XRD), microhardness tester, and friction and wear testing machine. The results showed that the main phases of the composite coatings were the γ-Co, Cr7C3, CoCx, WC, and W2C. The change of microhardness in the middle and lower parts of the composite coatings prepared by in-situ synthesized WC was smaller than that of the directly added WC. The best wear resistance was obtained for the composite coating with 12 wt% WC direct addition, which was slightly better than the composite coating with 3 wt% W in-situ. This is because when the amount of W was more than 6 wt%, some W particles could not be completely synthesized in situ in the friction test, and are easy to fall off, and the wear resistance of the cladding layer decreased sharply.

Similar content being viewed by others

References

Karmakar, D.P., Muvvala, G., Nath, A.K.: High-temperature abrasive wear characteristics of H13 steel modified by laser remelting and cladded with stellite 6 and stellite 6/30% WC. Surf. Coat. Technol. 422, 127498 (2021). https://doi.org/10.1016/j.surfcoat.2021.127498

Li, W., Xu, P.Q., Wang, Y.Y., Zou, Y., Gong, H.Y., Lu, F.G.: Laser synthesis and microstructure of micro- and nano-structured WC reinforced co-based cladding layers on titanium alloy. J. Alloys Compd. 749, 10–22 (2018). https://doi.org/10.1016/j.jallcom.2018.03.235

Han, T., Xiao, M., Zhang, Y., Shen, Y.: Effect of cr content on microstructure and properties of Ni-Ti-xCr coatings by laser cladding. Optik. 179, 1042–1048 (2019). https://doi.org/10.1016/j.ijleo.2018.11.044

Wang, G.Y., Zhang, J.Z., Shu, R.Y., Yang, S.: High temperature wear resistance and thermal fatigue behavior of Stellite-6/WC coatings produced by laser cladding with co-coated WC powder. Int. J. Refract. Met. Hard Mater. 81, 63–70 (2019). https://doi.org/10.1016/j.ijrmhm.2019.02.024

Weng, F., Yu, H.J., Liu, J.L., Chen, C.Z., Dai, J.J., Zhao, Z.H.: Microstructure and wear property of the Ti5Si3/TiC reinforced co-based coatings fabricated by laser cladding on Ti-6Al-4V. Opt. Laser Technol. 92, 156–162 (2017). https://doi.org/10.1016/j.optlastec.2017.01.014

Hu, M., Tang, J.C., Chen, X.G., Ye, N., Zhao, X.Y., Xu, M.M.: Microstructure and properties of WC-12Co composite coatings prepared by laser cladding. Trans. Nonferrous Met. Soc. China. 30(4), 1017–1030 (2020). https://doi.org/10.1016/s1003-6326(20)65273-6

Li, X., Zhang, C.H., Zhang, S., Wu, C.L., Liu, Y., Zhang, J.B., Babar Shahzad, M.: Manufacturing of Ti3SiC2 lubricated co-based alloy coatings using laser cladding technology. Opt. Laser Technol. 114, 209–215 (2019). https://doi.org/10.1016/j.optlastec.2019.02.001

Bartkowski, D., Kinal, G.: Microstructure and wear resistance of Stellite-6/WC MMC coatings produced by laser cladding using yb:YAG disk laser. Int. J. Refract. Met. Hard Mater. 58, 157–164 (2016). https://doi.org/10.1016/j.ijrmhm.2016.04.017

Chen, L., Chen, W.G., Li, D.Y., Jing, P.Y., Yin, H.Z., Wu, H.J., Xie, Y., Wang, X.N.: Effect of nano-La2O3 doping on the tribological behavior of laser cladded WC-12Co coating on 65Mn steel under water lubrication condition. Tribol. Int. 169, 107428 (2022). https://doi.org/10.1016/j.triboint.2022.107428

Ezquerra, B.L., Lozada, L., van den Berg, H., Wolf, M., Sánchez, J.M.: Comparison of the thermal shock resistance of WC based cemented carbides with Co and Co-Ni-Cr based binders. Int. J. Refract. Met. Hard Mater. 72, 89–96 (2018). https://doi.org/10.1016/j.ijrmhm.2017.12.021

Bartkowski, D., Młynarczak, A., Piasecki, A., Dudziak, B., Gościański, M., Bartkowska, A.: Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding. Opt. Laser Technol. 68, 191–201 (2015). https://doi.org/10.1016/j.optlastec.2014.12.005

Xu, G.J., Kutsuna, M.: Cladding with stellite 6 + WC using a YAG laser robot system. Surf. Eng. 22(5), 345–352 (2013). https://doi.org/10.1179/174329406X98430

Quan, X.M., Ding, L.: Microstructure and property of In-Situ TiC Reinforced Co-Based Composite Coatings by Laser Cladding. Sci. Adv. Mater. 11(12), 1798–1805 (2019). https://doi.org/10.1166/sam.2019.3610

Shu, D., Li, Z.G., Zhang, K., Yao, C., Li, D., Dai, Z.: In-situ synthesized high volume fraction WC reinforced Ni-based coating by laser cladding. Mater. Lett. 195, 178–181 (2017). https://doi.org/10.1016/j.matlet.2017.02.076

Wu, P., Du, H.M., Chen, X.L., Li, Z.Q., Bai, H.L., Jiang, E.Y.: Influence of WC particle behavior on the wear resistance properties of Ni–WC composite coatings. Wear. 257(1–2), 142–147 (2004). https://doi.org/10.1016/j.wear.2003.10.019

Tian, Z.H., Zhao, Y.T., Jiang, Y.J., Ren, H.P.: Microstructure and properties of Inconel 625 + WC composite coatings prepared by laser cladding. Rare Met. 40(8), 2281–2291 (2020). https://doi.org/10.1007/s12598-020-01507-0

Zhou, S.W., Xu, T.Y., Hu, C., Wu, H., Liu, H.L., Ma, X.Q.: A comparative study of tungsten carbide and carbon nanotubes reinforced Inconel 625 composite coatings fabricated by laser cladding. Opt. Laser Technol. 140, 106967 (2021). https://doi.org/10.1016/j.optlastec.2021.106967

Li, W.Y., Yang, X.F., Xiao, J.P., Hou, Q.M.: Effect of WC mass fraction on the microstructure and friction properties of WC/Ni60 laser cladding layer of brake discs. Ceram. Int. 47(20), 28754–28763 (2021). https://doi.org/10.1016/j.ceramint.2021.07.035

Ortiz, A., García, A., Cadenas, M., Fernández, M.R., Cuetos, J.M.: WC particles distribution model in the cross-section of laser cladded NiCrBSi + WC coatings, for different wt% WC. Surf. Coat. Technol. 324, 298–306 (2017). https://doi.org/10.1016/j.surfcoat.2017.05.086

Liu, J.D., Sun, W.L., Huang, Y.: Effect of carbon nanotubes content on microstructure and properties of WC/Ni laser cladding coatings. Surf. Eng. 37(5), 650–657 (2020). https://doi.org/10.1080/02670844.2020.1812481

Zhou, S.F., Xu, Y.B., Liao, B.Q., Sun, Y.J., Dai, X.Q., Yang, J.X., Li, Z.Y.: Effect of laser remelting on microstructure and properties of WC reinforced Fe-based amorphous composite coatings by laser cladding. Opt. Laser Technol. 103, 8–16 (2018). https://doi.org/10.1016/j.optlastec.2018.01.024

Dai, Q.L., Luo, C.B., You, F.Y.: Crack Restraining Methods and their Effects on the Microstructures and Properties of Laser Cladded WC/Fe Coatings. Materials. 11(12) (2018). https://doi.org/10.3390/ma11122541

Li, Q.T., Lei, Y.P., Fu, H.G.: Laser cladding in-situ NbC particle reinforced Fe-based composite coatings with rare earth oxide addition. Surf. Coat. Technol. 239, 102–107 (2014). https://doi.org/10.1016/j.surfcoat.2013.11.026

Zhang, M.M., Liu, B., Bai, P.K.: Microstructure and properties of laser cladding of 316L stainless steel on hydraulic support tube. J. Meas. Sci. Instrum. 8(2), 154–161 (2017). https://doi.org/10.3969/j.issn.1674-8042-2017-02-007

Ren, M.F., Li, R.F., Zhang, X.Q., Gu, J.Y., Jiao, C.: Effect of WC particles preparation method on microstructure and properties of laser cladded Ni60-WC coatings. J. Mater. Res. Technol. 22, 605–616 (2023). https://doi.org/10.1016/j.jmrt.2022.11.120

Xia, Y.L., Chen, H.N., Liang, X.D., Lei, J.B.: Circular oscillating laser melting deposition of nickel-based superalloy reinforced by WC: Microstructure, wear resistance and electrochemical properties. J. Manuf. Process. 68, 1694–1704 (2021). https://doi.org/10.1016/j.jmapro.2021.06.074

Farahmand, P., Liu, S., Zhang, Z., Kovacevic, R.: Laser cladding assisted by induction heating of Ni–WC composite enhanced by nano-WC and La2O3. Ceram. Int. 40(10), 15421–15438 (2014). https://doi.org/10.1016/j.ceramint.2014.06.097

Siddiqui, A.A., Dubey, A.K.: Recent trends in laser cladding and surface alloying. Opt. Laser Technol. (2021). 134https://doi.org/10.1016/j.optlastec.2020.106619

Ma, Q.S., Li, Y.J., Wang, J., Liu, K.: Homogenization of Carbides in Ni60/WC Composite Coatings made by Fiber laser remelting. Mater. Manuf. Processes. 30(12), 1417–1424 (2015). https://doi.org/10.1080/10426914.2015.1026353

Ferozhkhan, M.M., Kumar, K.G., Ravibharath, R.: Metallurgical study of stellite 6 cladding on 309-16L Stainless Steel. Arab. J. Sci. Eng. 42(5), 2067–2074 (2017). https://doi.org/10.1007/s13369-017-2457-7

Wang, C.Y., Luo, K.Y., Bu, X.Y., Su, Y.Y., Cai, J., Zhang, Q.L., Lu, J.Z.: Laser shock peening-induced surface gradient stress distribution and extension mechanism in corrosion fatigue life of AISI 420 stainless steel. Corros. Sci. 177 (2020). https://doi.org/10.1016/j.corsci.2020.109027

Yong, Y.W., Fu, W., Zhang, X., Deng, Q.L., Yang, J.G.: In-situ synthesis of WC/TaC Reinforced Nickel-Based Composite Alloy Coating by Laser Cladding. Rare Metal Materials and Engineering. 46(11), 3176–3181 (2017)

Shen, X.H., Peng, H., Xue, Y.N., Wang, B.L., Su, G.S., Zhu, J., Li, A.H.: Microstructure and Properties of WC/Ni-Based laser-clad Coatings with different WC content values. Materials. 15(18) (2022). https://doi.org/10.3390/ma15186309

Wu, Q.L., Li, W.G., Zhong, N., Gang, W., Haishan, W.: Microstructure and wear behavior of laser cladding VC–Cr7C3 ceramic coating on steel substrate. Mater. Design. 49, 10–18 (2013). https://doi.org/10.1016/j.matdes.2013.01.067

Li, Z.Y., Yan, H., Zhang, P.L., Guo, J.L., Yu, Z.S., Ringsberg, J.W.: Improving surface resistance to wear and corrosion of nickel–aluminum bronze by laser-clad TaC/Co-based alloy composite coatings. Surf. Coat. Technol. 405, 126592 (2021). https://doi.org/10.1016/j.surfcoat.2020.126592

Xu, P.H., Zhu, L.D., Xue, P.S., Yang, Z.C., Wang, S.H., Ning, J.S., Meng, G.R., Lan, Q., Qin, S.Q.: Microstructure and properties of IN718/WC-12Co composite coating by laser cladding. Ceram. Int. 48(7), 9218–9228 (2022). https://doi.org/10.1016/j.ceramint.2021.12.108

Cao, Q.Z., Fan, L., Chen, H.Y., Hou, Y., Dong, L.H., Ni, Z.W.: Wear behavior of laser cladded WC-reinforced Ni-based coatings under low temperature. Tribol. Int. 176, 107939 (2022). https://doi.org/10.1016/j.triboint.2022.107939

Raahgini, C., Verdi, D.: Abrasive wear performance of laser cladded Inconel 625 based metal matrix composites: Effect of the vanadium carbide reinforcement phase content. Surf. Coat. Technol. 429, 127975 (2022). https://doi.org/10.1016/j.surfcoat.2021.127975

Funding

This work was supported by the Natural Science Foundation of Hebei Province (No. E2021209026).

Author information

Authors and Affiliations

Contributions

Conceptualization: Haoqiang Zhang, Suoxia Hou; Methodology: Chengxiang Ren, Suoxia Hou; Formal analysis and investigation: Chengxiang Ren, Zhifeng Li; Writing - original draft preparation: Hao Liu, Chengxiang Ren; Writing - review and editing: Hao Liu; Funding acquisition: Haoqiang Zhang. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics Approval

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, H., Liu, H., Ren, C. et al. Microstructure and Properties of the Stellite6/WC Composite Coatings Prepared by Laser Cladding. Lasers Manuf. Mater. Process. 10, 645–658 (2023). https://doi.org/10.1007/s40516-023-00228-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-023-00228-3