Abstract

Though there are a variety of experimental techniques available for residual stress measurements, diffraction-based measurements have the unique advantage of estimating the individual components of the residual strain matrix in a crystalline material. This is then converted to residual stresses with appropriate continuum elasticity model(s) and X-ray elastic constants. In particular, measurements based on electron or neutron diffractions have their complexities or availability issues. The laboratory X-ray diffraction, on the other hand, may provide an easy resource and an effective tool. Such measurements range from two tilt methods to more extended d-sin2ψ measurements and multiple {hkil} grazing incident X-ray diffraction. Measurements can even be conducted on single crystals with micro-Laue diffraction and extended to stress ODF (orientation distribution function) calculations. These techniques are unquestionably extremely specialized, where measurement uncertainty plays an important role in the effectiveness plus reproducibility of the data. Unfortunately, standard textbooks or review articles typically describe some, but not all, of the techniques. In this overview, different techniques of X-ray diffraction for the determination of residual stresses in crystalline material have been summarized. It is hoped that potential users may benefit from the deliberations.

Similar content being viewed by others

References

Heindlhofer K, Evaluation of Residual Stress, McGraw-Hill Book Company (1948).

Osgood W R, Residual Stresses in Metals and Metal Construction, Reinhold Publishing Corporation (1954).

Almen J O, and Black P H, Residual Stresses and Fatigue in Metals, McGraw-Hill (1963).

Noyan I C, and Cohen J B, Residual Stress: Measurement by Diffraction and Interpretation, Springer (2013).

Withers P J, and Bhadeshia, H K D H, Residual Stress. Part 1, 355.

Cullity B D, Elements of X-ray Diffraction, Addison-Wesley Publishing (1956).

Verlinden B, Driver J, Samajdar I, and Doherty R D, Thermo-Mechanical Processing of Metallic Materials, Elsevier (2007).

Schneider E, Hauk V, Structural and Residual Stress Analysis by Nondestructive Methods, Elsevier, Amsterdam (1997), p 522.

Macherauch E, Adv Surf Treat 4 (2014) 1.

van Houtte P, and de Buyser L, Acta Metall Mater 41 (1993) 323.

Withers P J, and Bhadeshia H, Residual Stress. Part 1—Measurement Techniques (2016).

Bragg W L, Proc R Soc Lond Ser A Contain Pap Math Phys Charact 89 (1913) 248.

Loffe A F, and Kirpitcheva M, Phil Mag 43 (1922) 204.

Aksenov G J, Appl Phys (USSR) 6 (1929) 3.

Rossini N S, Dassisti M, Benyounis K Y, and Olabi A-G, Mater Des 35 (2012) 572.

Thool K, Patra A, Fullwood D, Krishna K V M, Srivastava D, and Samajdar I, Int J Plast 133 (2020) 102785.

Heyn E, J Inst Met 12 (1914) 1.

Creţu S S, and Popinceanu N G, Wear 105 (1985) 153.

Wawszczak R, Baczmański A, Braham C, Seiler W, Wróbel M, Wierzbanowski K, and Lodini A, Philos Mag 91 (2011) 2263.

Ortiz A L, Tian J W, Villegas J C, Shaw L L, and Liaw P K, Acta Mater 56 (2008) 413.

Bruno G, Ceretti M, Girardin E, Giuliani A, and Manescu A, Scr Mater 51 (2004) 999.

Carpenter K, and Tabei A, Materials 13 (2020) 255.

Zijlstra G, Groen M, Post J, Ocelík V, and de Hosson J T M, Mater Des 105 (2016) 375.

Noyan I C, Huang T C, and York B R, Crit Rev Solid State Mater Sci 20 (1995) 125.

Wang Z, and Gong B, Residual Stress in the Forming of Materials. Handbook of Residual Stress and Deformation of Steel (2002), p 141.

Bock H, Mechanische Eigenschaften von Wolframkarbid-Kobalt-Legierungen (1976).

Thomas G, Electron Microscopy and Strength of Crystals (1963).

Jiang J, Britton T B, and Wilkinson A J, Acta Mater 61 (2013) 5895.

Byeon J W, Liu J, Hopkins M, Fischer W, Garimella N, Park K B, Brady M P, Radovic M, El-Raghy T, and Sohn Y H, Oxid Met 68 (2007) 97.

Jain L, Bajpai R, Basu R, Misra D S, and Samajdar I, Cryst Growth Des 17 (2017) 1514.

Kumar G, Kanjarla A K, Lodh A, Singh J, Singh R, Srivastava D, Dey G K, Saibaba N, Doherty R D, and Samajdar I, Metall Mater Trans A 47 (2016) 3882.

van Acker K, de Buyser L, Celis J-P, and van Houtte P, J Appl Crystallogr 27 (1994) 56.

Marra W C, Eisenberger P, and Cho A Y, J Appl Phys 50 (1979) 6927.

Peng J, Ji V, Seiler W, Tomescu A, Levesque A, and Bouteville A, Surf Coat Technol 200 (2006) 2738.

Kohli D, Rakesh R, Sinha V P, Prasad G J, and Samajdar I, J Nucl Mater 447 (2014) 150.

Welzel U, Ligot J, Lamparter P, Vermeulen A C, and Mittemeijer E J, J Appl Crystallogr 38 (2005) 1.

Mukherjee D, Tewary U, Kumar S, Karagadde S, Verma R K, Sambandam M, and Samajdar I, Mater Sci Technol 36 (2020) 1020.

Kumar G, Kanjarla A K, Lodh A, Singh J, Singh R, Srivastava D, Dey G K, Saibaba N, Doherty R D, and Samajdar I, Metall Mater Trans A Phys Metall Mater Sci (2016). https://doi.org/10.1007/s11661-016-3526-3.

Kumar G, Lodh A, Singh J, Singh R, Srivastava D, Dey G K, and Samajdar I, CIRP J Manuf Sci Technol 19 (2017) 176.

Su R, Li L, Wang Y D, Nie Z H, Ren Y, Zhou X, and Wang J, AIP Adv 8 (2018) 55126.

Lodh A, Tak T N, Prakash A, Guruprasad P J, Hutchinson C, and Samajdar I, Metall Mater Trans A Phys Metall Mater Sci (2017). https://doi.org/10.1007/s11661-017-4280-x.

Lodh A, Tak T N, Prakash A, Guruprasad P J, Keralavarma S M, Benzerga A A, Hutchinson C, and Samajdar I, Metall Mater Trans A Phys Metall Mater Sci (2019). https://doi.org/10.1007/s11661-019-05421-8.

Lodh A, Tewary U, Singh R P, Tak T N, Prakash A, Alankar A, Guruprasad P J, and Samajdar I, Metall Mater Trans A Phys Metall Mater Sci (2018). https://doi.org/10.1007/s11661-018-4964-x.

Lodh A, Tak T N, Prakash A, Guruprasad P J, Hutchinson C, and Samajdar I, Metall Mater Trans A 48 (2017) 5317.

Kallend J S, and Huang Y C, Met Sci 18 (1984) 381.

Dorman M, Toparli M B, Smyth N, Cini A, Fitzpatrick M E, and Irving P E, Mater Sci Eng A 548 (2012) 142.

Sahoo S K, Hiwarkar V D, Krishna K V M, Samajdar I, Pant P, Pujari P K, Dey G K, Srivastav D, Tiwari R, and Banerjee S, Mater Sci Eng A 527 (2010) 1427.

He B B, Two-Dimensional X-ray Diffraction, John Wiley & Sons (2018).

Borbély A, and Groma I, Appl Phys Lett 79 (2001) 1772.

Ungár T, and Borbély A, Appl Phys Lett 69 (1996) 3173.

Vermeulen A C, Adv X-ray Anal 44 (2001) 128.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Residual Stress and Ewald Sphere Construction

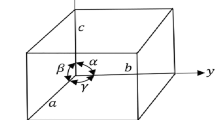

Let’s consider (see Fig. 11) the diffracting crystal at the center of Ewald sphere of 1/λ with incident beam entering from point A satisfying Bragg’s law. B defines the origin of reciprocal lattice. At no stress state condition, diffracted beam exits from point D. Therefore, length of vector DB is equal to \({\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 {d_{hkl} }}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{${d_{hkl} }$}}\). According to state of residual stress, diffraction peak will shift. Assuming compressive state here for the same crystal, diffracted beam now exits from point C and length of vector CB is equal to \({\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 {d_{{hkl, {\text{RS}}}} }}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{${d_{{hkl, {\text{RS}}}} }$}}\). The length difference between vector DB and CB arises from residual stress.

Rights and permissions

About this article

Cite this article

Lodh, A., Thool, K. & Samajdar, I. X-ray Diffraction for the Determination of Residual Stress of Crystalline Material: An Overview. Trans Indian Inst Met 75, 983–995 (2022). https://doi.org/10.1007/s12666-022-02540-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02540-6