Abstract

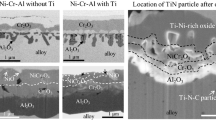

Ti2AlC ternary carbide is being explored for various high temperature applications due to its strength at high temperatures, excellent thermal-shock resistance, and high electrical conductivity. A potential advantage of Ti2AlC over conventional Al2O3-forming materials is the near-identical coefficient of thermal expansion (CTE) of Ti2AlC and α-Al2O3, which could result in superior spallation resistance and make Ti2AlC a promising option for applications ranging from bondcoats for thermal barrier coatings to furnace heating elements. In this study, isothermal and cyclic oxidation were performed in air to examine the oxidation behavior of Ti2AlC. Isothermal oxidation was performed at 1000, 1200 and 1400 °C for up to 25 h and cyclic oxidation consisted of 1,000 1-hour cycles at 1200 °C. Characteristics of the oxide scale developed in air, including mass change, residual stress in the α-Al2O3 scale, phase constituents and microstructure, were examined as functions of time and temperature by thermogravimetry, photostimulated luminescence, x-ray diffraction, scanning electron microscopy, and transmission electron microscopy via focused ion beam in situ lift-out. Above a continuous and adherent α-Al2O3 layer, a discontinuous-transient rutile-TiO2 scale was identified in the oxide scale developed at 1000 and 1200 °C, while a discontinuous-transient Al2TiO5 scale was identified at 1400 °C. The continuous α-Al2O3scale thickened to more than 15 μm after 25 h of isothermal oxidation at 1400 °C, and after 1,000 1-hour cycles at 1200 °C, yet remained adherent and protective. The compressive residual stress determined by photoluminescence for the α-Al2O3 scale remained under 0.65 GPa for the specimens oxidized up to 1400°C for 25 hours. The small magnitude of the compressive residual stress may be responsible the high spallation-resistance of the protective α-Al2O3 scale developed on Ti2AlC, despite the absence of reactive element additions.

Similar content being viewed by others

References

M. W. Barsoum, and T. El-Raghy, American Scientist 89, 334 (2001).

M. W. Barsoum, Progress in Solid State Chemistry 28, 201 (2000).

M. W. Barsoum, and T. El-Raghy, Journal of the American Ceramic Society 79, 1953 (1996).

M. W. Barsoum, T. El-Raghy, and L. U. J. Ogbuji, Journal of the Electrochemical Society 144, 2508 (1997).

Z. M. Sun, Y. C. Zhou, and M. S. Li, Corrosion Science 43, 1095 (2001).

Y. W. Bao, J. X. Chen, X. H. Wang, and Y. C. Zhou, Journal of the European Ceramic Society 24, 855 (2004).

X. H. Wang, and Y. C. Zhou, Acta Materialia 50, 3141 (2002).

X. H. Wang, and Y. C. Zhou, Corrosion Science 45, 891 (2003).

Z. J. Lin, M. J. Zhuo, Y. C. Zhou, M. S. Li, and J. Y. Wang, Scripta Materialia 54, 1815 (2006).

M. W. Barsoum, and M. Radovic, in Encyclopedia of Materials Science and Technology. K. H. J. Buschow, R. W. Cahn, M. C. Flemings, E. J. Kramer, S. Mahajan, P. Veyssiere, eds. (Elsevier Science).

R. Radovic, M. W. Barsoum, T. El-Raghy, S. Wiederhorn, and Luecke W, Acta Materialia 50, 1297 (2002).

M. A. Pietzka, and J. C. Schuster, Journal of Phase Equilibrium 15, 392 (1994).

M. W. Barsoum, D. Brodkin, and T. El-Raghy, Scripta Materialia 36, 535 (1997).

M. W. Barsoum, M. Ali, and T. El-Raghy, Metallurgical and Materials Transactions A A31, 1857 (2000).

X. H. Wang, and Y. C. Zhou, Zeitschrift fur MetaIlkunde 93, 66 (2002).

M. W. Barsoum, Journal of the Electrochemical Society 148, C544 (2001).

M. W. Barsoum, N. Tzenov, A. Procopio, T. El-Raghy, and M. Ali, Journal of the Eletrochemical Society 148, C551 (2001).

M. W. Barsoum, L. H. Ho-Duc, M. Radovic, and T. El-Raghy, Journal of the Electrochemical Society 150, B166 (2003).

X. H. Wang, and Y. C. Zhou, Oxidation of Metals 59, 303 (2003).

M. Sundberg, G. Malmqvist, A. Magnusson, and T. El-Raghy, Ceramics International 30, 1899 (2004).

S. Laxman, B. Franke, B. W. Kempshall, Y. H. Sohn, L. A Giannuzzi, and K. S. Murphy, Surface and Coatings Technology 177–178, 121 (2004).

B. A. Pint, Oxidation of Metals 45, 1 (1996).

Q. Ma, and D. R. Clarke, Journal of the American Ceramic Society 77, 298 (1994).

B. Pint, Unpublished Research.

B. Freudenberg, Journal of the American Ceramic Society 70, 1 (1987).

V. K. Tolpygo, J. R. Dryden, and D. R. Clarke, Acta Materialia 46, 927 (1998).

N. Mu, J. Liu, J. W. Byeon, Y. H. Sohn, and Y. L. Nava, Surface and Coatings Technology 188–189, 27 (2004).

C. Liu, A. M. Huntz, and J. L. Lebrun, Materials science & Engineering A A160, 113 (1993).

I. G. Wright, B. A. Pint, and P. F. Tortorelli, Oxidation of Metals 55, 333 (2001).

R. G. Munro, Journal of the American Ceramic Society 80, 1919 (1997).

P. Finkel, M. W. Barsoum, and T. El-Raghy, Journal of Applied Physics 87, 1701 (2000).

P. F. Tortorelli, K. L. More, E. D. Specht, B. A. Pint, and P. Zschack, Materials at High Temperatures 20, 303 (2003).

B. W. Veal, A. P. Paulikas, and R. C. Birtcher, Applied Physics Letters 89, 161916 (2006).

Z. J. Lin, M. J. Zhuo, Y. C. Zhou, M. S. Li, and J. Y. Wang, Journal of the American Ceramic Society 89, 2964 (2006).

Acknowledgements

The authors would like to thank Dr. B.A. Pint for assistance with cyclic oxidation testing and comparison data. J. Liu and W. Fischer have contributed to this study as an Amelia Earhart Fellow of Zonta International and a participant of NSF-RET program at UCF (EEC-0401926), respectively. M. P. Brady was funded at ORNL under the Fossil ARM program. ORNL is managed by UT-Battelle, LLC for the U.S. DOE under contract DE-AC05–00OR22725. Y. H. Sohn would also like to acknowledge financial support from NSF CAREER award (DMR-0238356). Assistant from Ms. Ashley Ewh, an undergraduate research assistant at UCF on manuscript preparation is sincerely appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Byeon, J.W., Liu, J., Hopkins, M. et al. Microstructure and Residual Stress of Alumina Scale Formed on Ti2AlC at High Temperature in Air. Oxid Met 68, 97–111 (2007). https://doi.org/10.1007/s11085-007-9063-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-007-9063-0