Abstract

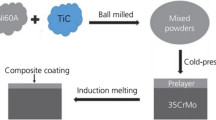

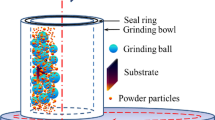

TiC–Ni composite coatings with different preheating temperatures were fabricated in situ on the H13 steel substrate by combustion synthesis combined with pseudo-heat isostatic press. The effects of preheating temperature on microstructure, surface porosity, mechanical properties and corrosion behaviour were investigated. The coatings were characterized by XRD, SEM–EDS and microhardness tester. The in situ composite coatings prepared at different preheating temperatures consisted of a network of Ni binder phase (white) and a spheroidal TiC phase (dark) embedded therein. The grain size of TiC, the proportion of the TiC-reinforced phase, surface hardness and interfacial bonding strength increased with increasing preheating temperature. The density and dimension of the AlNi3 phase after the immersion test decreased with an increase in preheating temperature. The corrosion mechanism of the coating was that the Ni binder phase was corroded by aluminium and the TiC phase got oxidized.

Similar content being viewed by others

References

Zhang X, He X, Han J, Qu W, and Kvalin V L, Mater Lett 56 (2002) 183.

Xiao G, Fan Q, Gu M, Wang Z, and Jin Z, Mat Sci Eng A Struct 382 (2004) 132.

Han J C, Zhang X H, and Wood J V, Mat Sci Eng A Struct 280 (2000) 328.

Fu Z, Mondal K, and Koc R S, Ceram Int 42 (2016) 9995.

Yang Y F, Wang H Y, Wang J G, and Jiang Q C, J Am Ceram Soc 91 (2008) 3813.

Dunmead S D, Readey D W, Semler C E, and Hol J B, J Am Ceram Soc 72 (1989) 2318.

Holt J B, J Mater Sci 21 (1986) 251.

Choi Y, and Rhee S W, J Mater Sci 30 (1995) 4637.

Manukyan K V, Lin Y C, Rouvimov S, McGinn P J, and Mukasyan A S, J Appl Phys 113 (2013) 024302.

Yang Y F, Wang H Y, Zhang J, Zhao R Y, Liang Y H, and Jiang Q C, J Am Ceram Soc 91 (2008) 2736.

Munir Z A, and Anselmi-Tamburini U, Mat Sci R 3 (1989) 277.

Yamada O, Miyamoto Y, and Koizumi M, J Am Ceram Soc 70 (1987) C-206.

Gopagoni S, Hwang J Y, Singh A R P, Mensah B A, Bunce N, Tiley J, Scharf T W, and Banerjee R, J Alloy Compd 509 (2011) 1255.

Azadmehr A, and Taheri-Nassaj E, J Non Cryst Solids 354 (2008) 3225.

Choi Y, and Rhee S W, J Mater Res 8 (1993) 3202.

Choi Y, and Rhee S W, J Mater Sci 28 (1993) 6669.

Saidi A, Chrysanthou A, Wood J V, and Kellie J L F, J Mater Sci 29 (1994) 4993.

Zhang W, Zhang X, Wang J, and Hong C, Mat Sci Eng A Struct 381 (2004) 92.

LaSalvia J C, Kim D K, and Meyers MA, Mat Sci Eng A Struct 206 (1996) 71.

Zarrinfar N, Shipway P H, Kennedy A R, and Saidi A, Scr Mater 46 (2002) 121.

Yang Y F, Wang H Y, Wang J G, and Jiang Q C, J Alloy Compd 509 (2011) 7060.

Durlu N, J Eur Ceram Soc 19 (1999) 2415.

Lemboub S, Boudebane S, Gotor F J, Haouli S, Mezrag S, Bouhedja S, Hesser G, Chadli H, and Chouchane T, Int J Refract Metals Hard Mater 70 (2018) 84.

Stolin A M, and Bazhin P M, Int J Self Propag High Temp Synth 23 (2014) 65.

Boromei I, Casagrande A, Tarterini F, Poli G, Veronesi P, and Rosa R, Surf Coat Technol 204 (2010) 1793.

Liu Z D, Tian J, Li B, and Zhao L P, Mat Sci Eng A Struct 527 (2010) 3898.

Odawara O, and Ikeuchi J, Trans Jpn Inst Met 27 (1986) 702.

Odawara O, Trans Jpn Inst Metals 26 (1985) 578.

Odawara O, J Am Ceram Soc 73 (1990) 629.

Yang Y W, Fu Z Y, and Yuan R Z, J Wuhan Univ Technol 18 (2003) 14.

He S, Fan X A, Chang Q, and Xiao L, Metall Mater Trans B 48 (2017) 1748.

Boutefnouchet H, Curfs C, Triki A, Boutefnouchet A, and Vrel D, Powder Technol 217 (2012) 443.

Yang Y F, Wang H Y, Zhao R Y, Liang Y H, Zhan L, and Jiang Q C, J Alloy Compd 460 (2008) 276.

Yang Y F, Wang H Y, Liang Y H, Zhao R Y, and Jiang Q C, Mat Sci Eng A Struct 474 (2008) 355.

Ye L L, Huang J Y, Liu Z G, Quan M X, and Hu Z Q, J Mater Res 11 (1996) 2092.

Choi Y, Lee J K, and Mullins M E, J Mater Sci 32 (1997) 1717.

Huang L, Wang H Y, Qiu F, and Jiang Q C, Mat Sci Eng A Struct 422 (2006) 309.

Li Y X, Bai P K, Wang Y M, Hu J D, and Guo Z X, Int J Refract Metals Hard Mater 27 (2009) 552.

Zhu G, Wang W, Wang R, Zhao C, Pan W, Huang H, Du D, Wang D, Shu D, Dong A, Sun B, Jiang S, and Pu Y, Materials 10 (2017) 1007.

Sierra C, and Vázquez A J, Sol Energ Mat Sol C 86 (2005) 33.

Riley D P, Intermetallics 14 (2006) 770.

Wang H, Zhang S, Zhu J, Huang J, Liu H, and Zhang H, J Therm Spray Tech 18 (2009) 103.

Yang S, Zhong M, and Liu W, Mat Sci Eng A Struct 343 (2003) 57.

Mogonye J E, Srivastava A, Gopagoni S, Banerjee R, and Scharf T W, Tribol Lett 64 (2016) 37.

Humenik M, and Parikh N M, J Am Ceram Soc 39 (1956) 60.

Ye D L, and Hu J H, Practical inorganic thermodynamics manual, Metallurgical Industry Press, Beijing (2002).

Merzhanov A G, an`ya I P, Dokl Akad Nauk SSSR 204 (1972) 366.

Wei M X, Wang S Q, Wang F, and Cui X H, Mater Des 30 (2009) 3041.

Boutefnouchet H, and Vrel D, Int J Self Propag High Temp Synth, 25 (2016) 67.

Wong J, Larson E M, Holt J B, Waide P A, Rupp B, and Frahm R, Science 249 (1990) 1406.

Munir Z A. J Mater Synth Process 1 (1993) 387.

Morsi K, J Mater Sci 47 (2012) 68.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51375353 and No. 51475346).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, C., Shi, J., Wei, J. et al. Effect of Preheating Temperature on the Microstructure and Corrosion Resistance of TiC–Ni Coating by CS/PHIP. Trans Indian Inst Met 72, 1869–1879 (2019). https://doi.org/10.1007/s12666-019-01664-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01664-6