Abstract

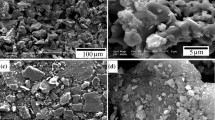

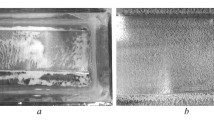

In the present study, the effects of an alumina layer and its thickness on the bonding behavior of Al/Al strips were evaluated. To achieve this, aluminum strips were anodized at different times to generate alumina layers with various thicknesses. Furthermore, some samples were produced with alumina powder and the bond strength of these samples was compared with that of samples produced by the alumina layer. After the cold roll bonding process, peel test was carried out to evaluate the bond strength and weld efficiency of Al strips. The results of the peel test indicated that using a thin alumina layer (5 μm) led to a decrease in weld efficiency. However, by increasing the thickness of the alumina layer, weld efficiency also increased, reaching a higher level compared to Al strips without the anodized layer. Moreover, using alumina powder caused the deterioration of the bond strength compared with the samples fabricated by anodized alumina layer.

Similar content being viewed by others

References

Torralba J M, da Cost C E, and Velasco F, J Mater Process Technol 133 (2003) 203

Dobrzanski L A, WEodarczyk A, and Adamiak M, J Mater Process Technol 175 (2006) 186

Abdel Aziz M, Mahmoud T S, and Abdel Aal A, Mater Sci Eng A 486 (2008) 313

Lee D W, and Kim B K, Mater Lett 58 (2004) 378

Lu C, Tieu K, and Wexler D, J Mater Process Technol 209 (2009) 4830

Alizadeh M, and Paydar M H, J Alloys Compd 492 (2010) 231

Yazdani A, and Salahinejad E, Mater Des 32 (2011) 3137

Alizadeh M, J Alloys Compd 509 (2011) 2243

Jamaati R, and Toroghinejad M R, Mater Sci Eng A 527 (2010) 4146

Rezayat M, Akbarzadeh A, and Owhadi A, Compos A 43 (2012) 261

Jamaati R, Toroghinejad M R, Dutkiewicz J, and Szpunar J A, Mater Des 35 (2012) 37

Jamaati R, and Toroghinejad M R, Mater Des 31 (2010) 4816

Shabani A, Toroghinejad M R, and Shafyei A, Mater Sci Eng A 558 (2012) 386

Dehkordi H, Toroghinejad M R, and Raeissi K, Mater Sci Eng A 585 (2013) 460

Ahmadi A, Toroghinejad M R, and Najafizadeh A, Mater Des 53 (2014) 13

Jamaati R, and Toroghinejad M R, Mater Sci Eng A 527 (2010) 2320

Alizadeh M, J Mater Sci 47 (2012) 4689

Madaah-Hosseini H R, and Kokabi A H, Mater Sci Eng A 335 (2002) 186

Alizadeh M, and Paydar M H, Mater Des 30 (2009) 82

Rezayat M, and Akbarzadeh A, Mater Des 36 (2012) 874

Akramifard H R, Mirzadeh H, and Parsa M H, Mater Sci Eng A 613 (2014) 232

Shabani A, Toroghinejad M R, and Shafyei A, Mater Des 40 (2012) 212

Yousefi Mehr V, Toroghinejad M R, and Rezaeian A, Mater Des 53 (2014) 174

Eizadjou M, Manesh H, and Janghorban K, Mater Des 30 (2009) 4156

H. Danesh Manesh, and A. Karimi Taheri, Mater Des 24 (2003) 617

Vaidyanath L R, Nicholas M G, and Milner D R, Br Weld J 6 (1959) 13

Mohamed H A, and Washburn J, Weld J 54 (1975) 302

Long L, Kotobu N, and Fuxing Y, Sci Technol Adv Mater 9 (2008) 1

Cepeda-Jimenez C M, Pozuelo M, Garcia-Infanta J M, Ruano O A, and Carreno F, Mater Sci Eng A 496 (2008) 133

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dehlordi, H.F., Toroghinejad, M.R. & Raeissi, K. An Investigation of the Bonding Behavior of Aluminum Strips in the Presence of an Alumina Layer During the Cold Roll Bonding Process. Trans Indian Inst Met 72, 685–691 (2019). https://doi.org/10.1007/s12666-018-1520-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1520-8